Why Rice Husk is India’s Most Practical Biomass Fuel

Rice husk, the outer shell of the rice grain, forms about 20% of the paddy weight. Its practicality stems from a perfect alignment of availability, cost, and logistics within India’s massive agro-industrial ecosystem.

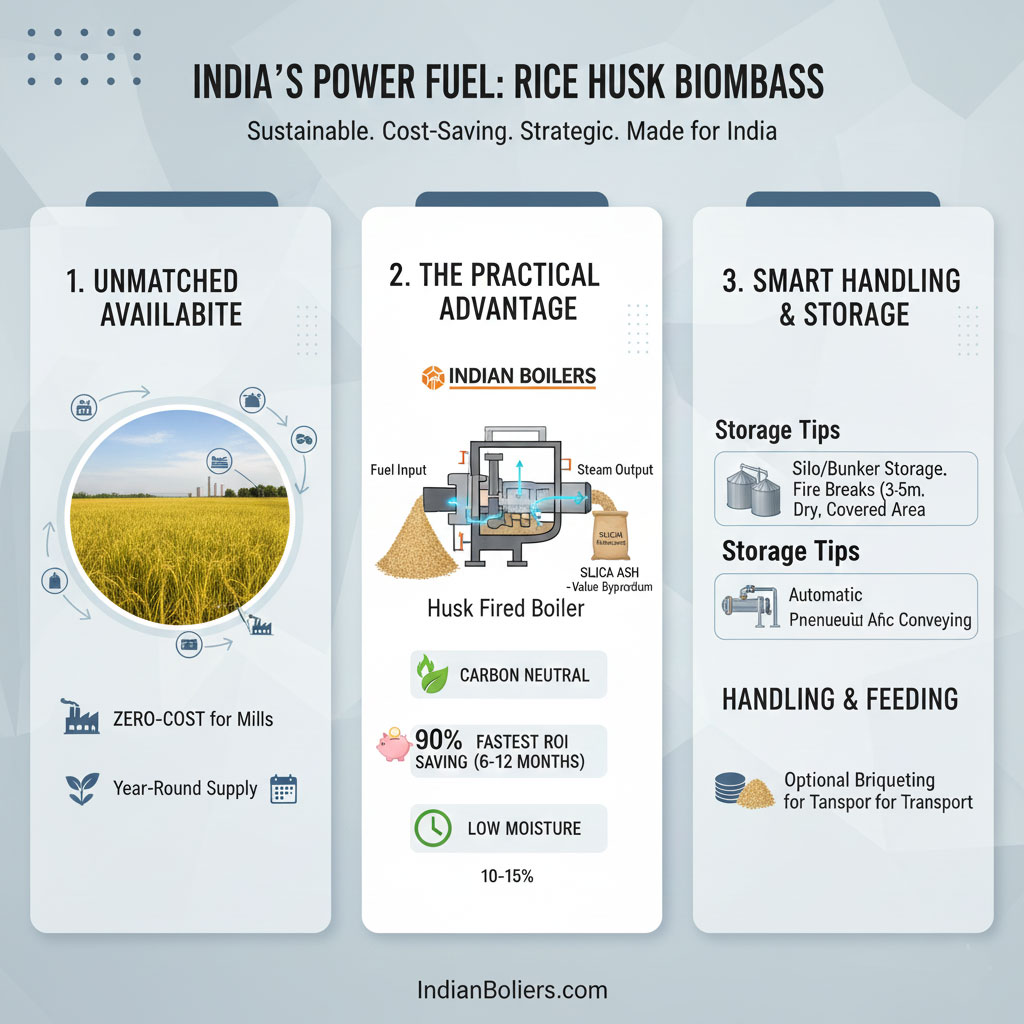

1. Unmatched Availability and Cost Advantage

India is one of the world’s largest rice producers, guaranteeing a massive, decentralized, and year-round supply of husk.

| Factor | Rice Husk Advantage | Strategic Implication for Industry |

| Availability | Produced in millions of tonnes annually as a non-seasonal, non-cyclical waste product of rice milling. | Highly Reliable Supply Chain: Industries located near rice belts (e.g., Punjab, Haryana, Andhra Pradesh, West Bengal) have a stable, local fuel source, reducing supply risk. |

| Cost | Often a zero-cost fuel for rice mills, as it is a necessary waste product they must dispose of. For other industries, it is significantly cheaper than coal, oil, or gas. | Drastic Cost Reduction: The fuel cost component of steam generation plummets, leading to a much faster Return on Investment (ROI) on the boiler. |

| Carbon Footprint | It is a Carbon-Neutral Fuel. The CO2 released during combustion was absorbed by the rice plant during its growth cycle. | Sustainability Compliance: Helps industries meet evolving corporate sustainability goals and potentially qualify for green financing or carbon offset programs. |

2. Comparative Edge Against Other Biomass

While other biomass fuels like Bagasse or Wood Chips are used, Rice Husk offers unique advantages for non-sugar industries:

| Property | Rice Husk | Sugarcane Bagasse | Why Husk is often More Practical |

| Primary Source | Rice Mills (Decentralized, widespread) | Sugar Mills (Centralized, seasonal) | Wider Geographic Availability and less seasonal price fluctuation for most non-sugar industries. |

| Moisture Content | Low 10% – 15% | High (up to 50% when wet) | Higher Net Calorific Value for combustion, requiring minimal or no pre-drying, improving boiler efficiency. |

| Fuel Density | Low (Loose form) | Medium (Fibrous) | For rice mills, it’s used directly where it’s created, eliminating the need for complex, costly densification processes often needed for Bagasse transport. |

Note: While Rice Husk has a lower calorific value (approx 3,200 – 3,800kcal/kg than coal approx 6,000 kcal/kg, its near-zero cost often outweighs the slightly lower energy density, making it economically superior.

3. Handling & Storage Tips for Rice Husk Biomass

Due to its unique properties—low bulk density, flammability, and high silica ash—Rice Husk requires specific handling and storage protocols to ensure safety and preserve its quality.

A. Storage Best Practices (Preventing Loss and Fire)

| Challenge | IndianBoilers.com Recommended Solution |

| Low Bulk Density | Use Dedicated Silos or Bunkers: Loose rice husk occupies a large volume (approx 2.5 to 3 m3 per tonne). Utilize high-volume, purpose-built storage that is close to the boiler to minimize conveying distances. |

| Fire Hazard | Stockpile Separation & Fire Breaks: Store husk in designated piles with a 3 – 5 meter distance between them. Implement fire safety measures, including fire extinguishers, and ensure storage is away from open flames, sparks, and heat sources. |

| Moisture Control | Dry Storage/Elevated Platforms: Although rice husk is naturally low in moisture, protect it from rain. Store large piles under covered sheds or on raised concrete/pallet platforms to prevent ground moisture absorption, which degrades its calorific value. |

| Ageing & Quality | Implement FIFO (First-In, First-Out): Rotate inventory to ensure older husk is used first. Although husk is stable, proper rotation maintains consistent fuel quality for boiler operation. |

B. Handling and Feeding

- Pneumatic Conveying: Given its lightweight, loose form, the most efficient way to transport husk from storage to the boiler is via a Fully Automatic Pneumatic Feeding System. This uses high-velocity air (via a fan) to move the material through pipelines, minimizing spillage and labour.

- Densification (Optional): For industries far from rice mills, the high transportation cost of loose husk can be prohibitive. In this case, purchasing Rice Husk Briquettes or Pellets is advised. Densification increases the bulk density from approx 150 kg/m3 (loose) to approx 600 – 800 kg/m3 (pellets), making transport cost-effective.

- Dust Mitigation: Since rice husk handling generates fine dust, ensure the feeding system is enclosed and a dust collection or suppression system is installed in the loading and unloading areas to maintain plant hygiene and safety.

By strategically utilizing this practical, abundant, and cost-effective fuel source, Indian industries can achieve significant operational savings while contributing positively to the nation’s energy independence and environmental goals.

Are you interested in a detailed comparison of the boiler technologies (like Top Feed vs. FBC) used to efficiently burn rice husk?