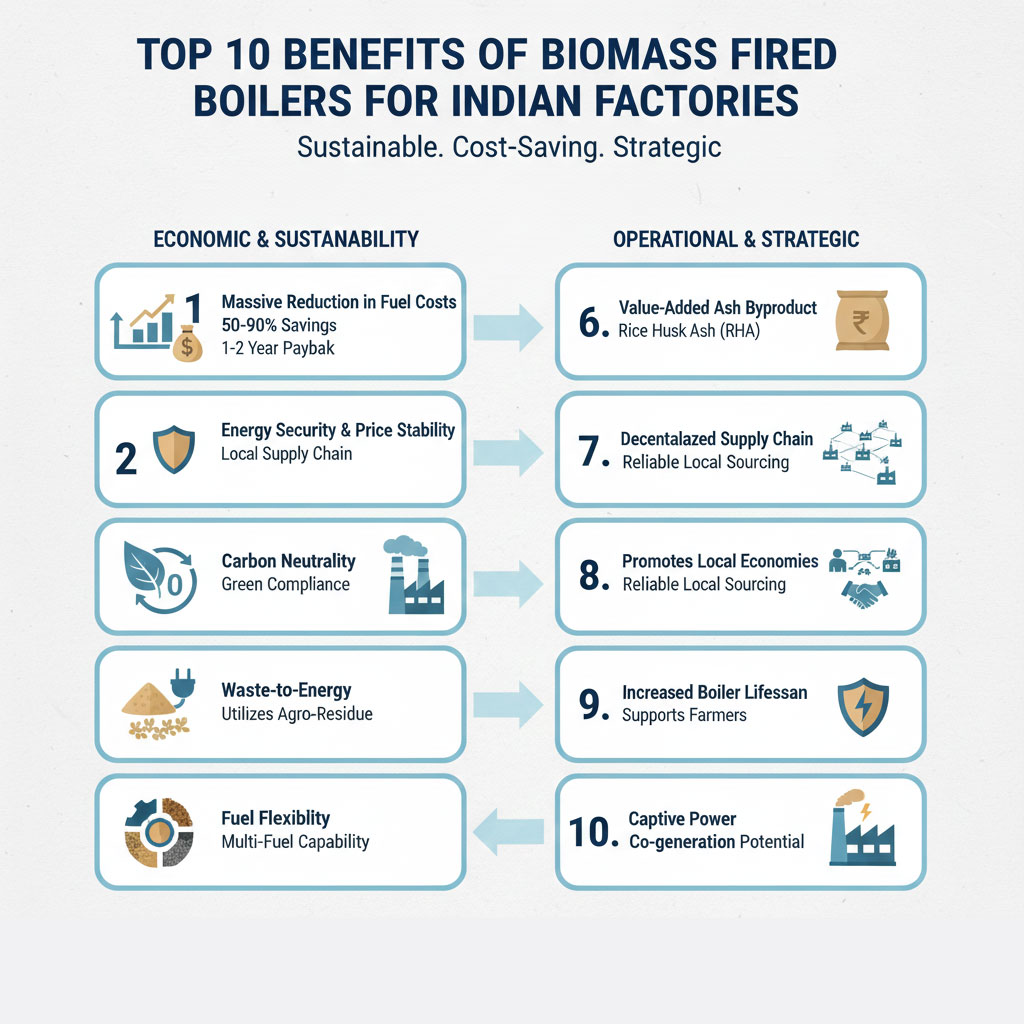

Top 10 Benefits of Biomass Fired Boilers for Indian Factories

The transition from fossil fuels to biomass in industrial steam generation is rapidly accelerating across India. For factory owners and plant managers, adopting a Biomass Fired Boiler (especially those designed for fuel like rice husk, bagasse, and wood chips) is not just an environmental choice—it is a shrewd economic and strategic decision.

Here are the top 10 compelling benefits of installing a biomass-fired hot water boiler from IndianBoilers.com in your factory:

1. Massive Reduction in Fuel Operating Costs (Highest ROI)

Biomass fuels, being agricultural waste products, are significantly cheaper than coal, furnace oil, or diesel. For factories located near agricultural hubs or those that generate their own waste (like rice mills or sugar mills), the fuel cost can be near-zero. This immense reduction in the operational fuel bill results in the fastest Return on Investment (ROI), often achieving payback periods of 1 to 2 years.

2. Energy Security and Price Stability

Indian factories are constantly exposed to volatile global crude oil and coal prices. Biomass is a domestic, local resource.

- Insulation from Global Markets: You are protected from international price hikes, geopolitical events, and currency fluctuations.

- Predictable Budgeting: Localized pricing allows for more accurate and stable long-term energy budgeting.

3. Achieving Carbon Neutrality and Green Compliance

Biomass is the bedrock of corporate sustainability.

- Closed Carbon Cycle: Burning biomass releases CO2 that was absorbed during the plant’s growth, leading to a net-zero carbon contribution. This is crucial for meeting corporate Environmental, Social, and Governance (ESG) mandates and securing international supply contracts.

- Regulatory Compliance: It helps factories meet India’s increasingly stringent emission norms and pollution control board (PCB) requirements without expensive SOx scrubbers or NOx control systems.

4. Utilization of Agricultural Waste (Waste-to-Energy)

Biomass boilers solve the problem of agricultural waste disposal, turning a liability into an asset. This is particularly relevant in India, where waste disposal is a major challenge. Using biomass prevents practices like the burning of crop residue, which is a significant source of air pollution.

5. Fuel Flexibility in Modern Boiler Design

Advanced biomass boilers, particularly those utilizing Fluidized Bed Combustion (FBC) technology, are engineered for high fuel flexibility.

- Your boiler can efficiently burn a mix of rice husk, groundnut shells, bagasse, wood pellets, and even low-grade coal, ensuring steam generation continues even if one local fuel source becomes temporarily unavailable or expensive.

6. Value-Added Ash Byproducts

Unlike coal ash, the ash produced by many biomass fuels, especially Rice Husk Ash (RHA), is a marketable commodity.

- RHA is rich in silica (SiO2) and is highly sought after by the cement, concrete, and refractory industries, creating an additional revenue stream that further offsets boiler operational costs.

7. Decentralized and Reliable Supply Chain

Biomass is available in almost every state in India, close to agricultural processing units. This decentralized sourcing model reduces the dependency on long-distance, complex logistics networks required for coal or oil, making the supply more resilient and reliable.

8. Promotion of Local Economies

Sourcing biomass fuels directly supports local farmers, traders, and transportation networks in the nearby rural economy. This aligns industrial operations with local social responsibility goals and builds goodwill within the community.

9. Increased Boiler Lifespan with Specialized Technology

Modern biomass boilers are specifically engineered to handle the unique properties of agro-fuels (e.g., high silica, low density).

- Features like specialized combustion chambers, anti-erosion mechanisms (e.g., ferrules in husk boilers), and high-efficiency Multi-Cyclone Dust Collectors (MCDC) protect critical boiler components, ensuring extended operational life and reduced downtime compared to traditional designs attempting to burn challenging fuels.

10. Potential for Captive Power Generation

Biomass boilers, particularly those generating higher pressure steam, are excellent candidates for co-generation or trigeneration.

- Factories can install a small back-pressure or extraction-condensing turbine to generate captive electricity using the steam, effectively transforming the boiler into an integrated heat and power (CHP) unit, maximizing energy efficiency and minimizing reliance on expensive grid power.

Ready to calculate the substantial savings a Biomass Fired Boiler can bring to your factory?

Contact IndianBoilers.com today for a complimentary energy audit and ROI projection.