Rice Husk Fired Boiler vs. Coal/Diesel: A Head-to-Head for Indian Plants

For decades, coal and diesel (furnace oil) have been the backbone of industrial steam generation in India. However, with volatile fossil fuel prices, increasing environmental regulations, and a strong push for sustainability, Rice Husk Fired Boilers are emerging as a superior alternative.

At IndianBoilers.com, we understand that investment decisions are driven by hard numbers. This guide provides a direct comparison of Rice Husk, Coal, and Diesel boilers across critical parameters: Operating Cost, Maintenance, and Payback Period—tailored for the Indian industrial context.

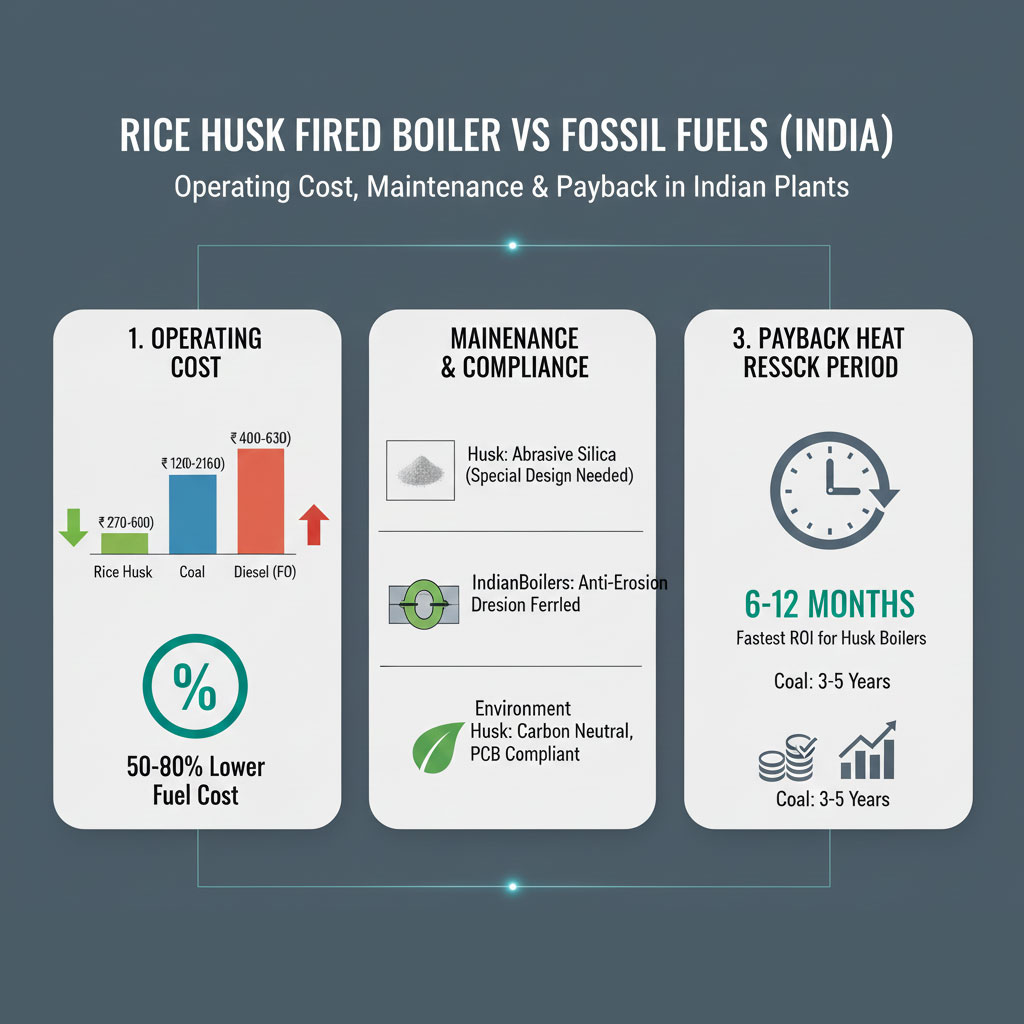

1. Operating Cost: The Game Changer

This is where Rice Husk Boilers deliver their most significant impact. The vast difference in fuel cost drastically alters the economic landscape for steam generation.

A. Fuel Cost per Tonne of Steam (Illustrative Example)

Let’s consider a typical 4 TPH boiler operating for 20 hours a day, 300 days a year (total 24,000 tonnes of steam per annum). Fuel prices are illustrative and subject to market fluctuations but reflect general trends in India.

| Parameter | Rice Husk Fired Boiler | Coal Fired Boiler | Oil Fired Boiler |

| Fuel Type | Rice Husk (biomass) | Non-Coking Coal | Furnace Oil (FO) / HSD |

| Typical Fuel Price (per tonne/litre) | ₹ 1,000 – 2,000(or near zero for rice mills) | ₹ 8,000 – 12,000 | ₹ 50 – 70 per litre |

| Efficiency | 75% – 80% | 70% – 75% | 85% – 90% |

| Fuel Consumption per TPH of Steam | approx 270 – 300 kg | approx 150 – 180 kg | approx 80 – 90 Litres |

| Fuel Cost per TPH of Steam | ₹ 270 – 600 | ₹ 1,200 – 2,160 | ₹ 4,000 – 6,300 |

| Annual Fuel Cost for 24,000 TPH | ₹ 64.8 Lacs – 1.44 Crores | ₹ 2.88 Lacs – 5.18 Crores | ₹ 9.6 Lacs – 15.12 Crores |

Key Takeaway: Even at the higher end of the husk price, the annual fuel cost for a Rice Husk Fired Boiler is often 50% to 90% lower than coal and significantly less than diesel. For rice mills using their own husk, the fuel cost is virtually zero.

B. Auxiliary Power Consumption (APC)

- Rice Husk: Requires higher APC due to pneumatic conveying fans for fuel feeding and often larger ID/FD fans to handle the voluminous flue gases.

- Coal: Moderate APC for fuel feeders and ID/FD fans.

- Diesel: Lowest APC as fuel is pumped directly, and air requirements are lower.

Mitigation: While husk boilers have higher APC, the immense fuel cost savings easily offset this. Many plants even use a small back-pressure turbine with their husk boiler to generate captive power, making the system energy neutral or even a power generator.

C. Manpower

- Rice Husk: Automatic feeding systems (pneumatic/screw) reduce manual labour for fuel loading. Ash handling can also be automated.

- Coal: Requires significant labour for manual coal feeding and ash removal in older designs. Modern AFBC boilers automate much of this.

- Diesel: Requires minimal manpower.

2. Maintenance & Operational Challenges

Each fuel presents unique maintenance considerations.

A. Boiler Maintenance

| Factor | Rice Husk Fired Boiler | Coal Fired Boiler | Diesel Fired Boiler |

| Ash Handling | High volume, highly abrasive silica ash. Requires specialized Multi-Cyclone Dust Collectors (MCDC) and protective ferrules/caps in tubes. More frequent tube cleaning. | High volume, but less abrasive ash than husk. | Minimal ash. Easiest in terms of ash handling. |

| Tube Erosion | Higher risk due to abrasive silica ash if not properly designed. IndianBoilers’ specific designs (ferrules, proper velocity control) mitigate this. | Moderate risk. | Very low risk. |

| Scaling/Sooting | Lower tendency for hard scaling if water treatment is good. Soot blowing needed. | Moderate scaling, regular soot blowing. | Low sooting, easiest to clean. |

| Refractory Life | High furnace temperatures demand quality refractory. Life generally good with proper operation. | Good. | Excellent. |

IndianBoilers.com Advantage: Our Huskpower boilers are specifically engineered for Indian rice husk, incorporating features like robust MCDC, anti-erosion ferrules, and optimal flue gas velocity control to minimize maintenance challenges and extend boiler life.

B. Environmental Compliance & Emissions

- Rice Husk: Carbon neutral. Minimal SOx. NOx and Particulate Matter (PM) easily managed with MCDC. Complies with current and future environmental norms.

- Coal: High CO2, SOx, NOx, and PM. Requires expensive pollution control equipment (ESP/Bag Filters, FGD) for compliance, especially for larger units.

- Diesel: Moderate CO2, SOx, NOx,. Generally easier to meet emission norms for smaller units, but still a fossil fuel.

3. Payback Period: The Decisive Factor

The Payback Period is the time it takes for the cost savings to cover the initial investment. This is where Husk Fired Boilers truly shine in the Indian context.

A. Initial Capital Cost (Illustrative for a 4 TPH Boiler)

| Boiler Type | Initial Capital Cost (Illustrative) |

| Rice Husk Fired Boiler | ₹ 80 Lacs – 1.2 Crores |

| Coal Fired Boiler | ₹ 70 Lacs – 1.1 Crores |

| Diesel Fired Boiler | ₹ 60 Lacs – 90 Lacs |

Note: Capital costs can vary significantly based on automation, pressure, and specific features.

B. Calculating Payback

Assuming a Rice Mill using its own husk (near-zero fuel cost) and comparing it to buying a new Coal Fired Boiler:

- Annual Fuel Savings (Husk vs. Coal): approx ₹ 2.88 Crores – ₹ 5.18Crores (from section 1.A)

- Additional Capital Cost for Husk Boiler (vs. Coal): approx ₹ 10 Lacs (Husk boiler might be slightly more due to specialized feeding/ash handling)

Estimated Payback Period for Husk Boiler: Given the massive fuel savings, the additional capital cost for a Husk Fired Boiler can be recovered in as little as 6 months to 1 year, making it one of the fastest ROI investments for an Indian industrial plant. Even for units purchasing husk, the payback is typically within 1-2 years.

Conclusion: The Smart Switch

For Indian industries, the choice is clear:

- Rice Husk Fired Boilers offer unparalleled operating cost savings, rapid payback periods, and strong environmental advantages. While initial capital or maintenance requires attention, these are overwhelmingly offset by fuel cost benefits.

- Coal Fired Boilers face increasing scrutiny, volatile prices, and high pollution control costs.

- Diesel Fired Boilers are easy to operate but are the most expensive, making them unsuitable for continuous, high-volume steam generation.

By choosing a Rice Husk Fired Boiler from IndianBoilers.com, you’re not just buying a machine; you’re investing in a future of sustainable, cost-effective, and compliant industrial operations.

Ready to calculate your exact savings?

Contact Indianboilers.com experts today for a personalized financial projection for your plant.