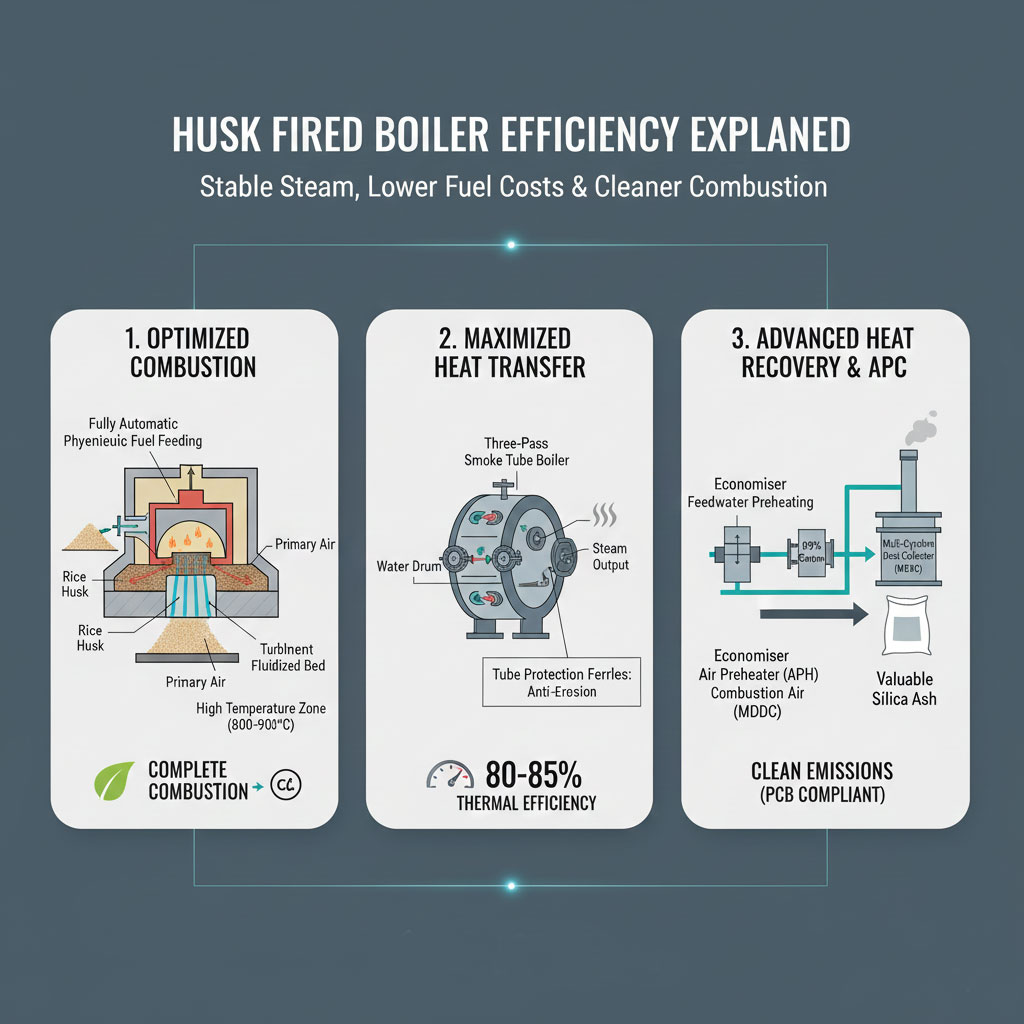

Husk Fired Boiler Efficiency Explained: How to Achieve Stable Steam, Lower Fuel Cost & Cleaner Combustion

In the competitive landscape of Indian manufacturing, optimizing operational efficiency is no longer an option, but a necessity. For steam-intensive industries, this directly translates to how effectively their boilers convert fuel into usable steam. While rice husk offers an undeniable cost advantage as a fuel, the true long-term benefit comes from a highly efficient Husk Fired Boiler that guarantees stable steam, maximum fuel savings, and clean combustion.

At IndianBoilers.com, we specialize in engineering Husk Fired Boilers that excel in these critical areas. Let’s break down the science behind their superior performance.

1. Optimized Combustion: The Heart of Efficiency

The first step to efficiency lies in burning the fuel completely and effectively. Husk, with its unique properties (low density, high volatile matter, high ash), demands a specialized approach.

- A. Advanced Combustion Technologies:

- Internal Furnace with Top Feed System: For capacities typically up to 6 TPH, IndianBoilers.com utilizes a robust internal furnace design. Husk is fed pneumatically from the top, creating a stable, controlled fuel bed. Primary air from below the grate ensures initial combustion, while carefully distributed secondary air above the fuel bed completes the combustion of volatile gases. This two-stage air supply mechanism ensures maximum heat release.

- Fluidized Bed Combustion (FBC): For larger capacities (from 4 TPH upwards), FBC technology is paramount. Here, the husk is introduced into a hot bed of inert material (like sand) that is “fluidized” by high-velocity air. The turbulent mixing in the bed ensures:

- Uniform Temperature Distribution: Consistent combustion across the entire bed.

- Long Residence Time: Husk particles spend more time in the high-temperature zone, ensuring complete burnout.

- High Combustion Efficiency: FBC can achieve 95% combustion efficiency, leaving minimal unburnt carbon in the ash.

- B. Automated Fuel Feeding:

- Consistent Supply: Fully automatic pneumatic feeding systems ensure a continuous and uniform supply of husk to the furnace, preventing fluctuations in the fuel bed that can lead to unstable steam pressure or incomplete combustion. This contrasts sharply with manual feeding, which is prone to inconsistencies.

- Optimized Air-Fuel Ratio: Modern boilers integrate combustion air control systems that automatically adjust primary and secondary air flows based on steam demand, optimizing the air-to-fuel ratio for peak efficiency.

2. Maximized Heat Transfer: Turning Heat into Usable Steam

Once the heat is generated, the boiler’s design dictates how efficiently that heat is transferred to the water to produce steam.

- A. Three-Pass Design:

- Our Husk Fired Boilers typically employ a three-pass design. This means the hot flue gases travel through the boiler a minimum of three times before exiting to the stack. Each “pass” allows for more contact time between the hot gases and the water-filled tubes, maximizing heat absorption.

- Wet Back Design: A “wet back” arrangement (where the back end of the furnace is surrounded by water) further increases the heat transfer area and reduces radiation losses, contributing significantly to overall efficiency.

- B. Tube Protection Against Silica Ash:

- The Silica Challenge: Husk contains a high percentage of silica ash (up to 25%, which is abrasive. Without protection, this ash can erode boiler tubes, reducing their lifespan and diminishing heat transfer efficiency.

- Protective Ferrules: IndianBoilers.com strategically places special ferrules (protective inserts) at the entrance of smoke tubes. These ferrules bear the brunt of the abrasive action, shielding the main tube material and maintaining optimal heat transfer surfaces for a longer operational life.

- C. Minimal Radiation Losses:

- The use of robust insulation and, in the case of internal furnace designs, the “wet back” configuration, significantly minimizes heat loss from the boiler’s surface to the ambient air. Lower radiation losses mean more heat is directed towards steam generation.

3. Advanced Heat Recovery & Air Pollution Control (APC)

True efficiency extends beyond the main boiler unit to integrated systems that recover waste heat and ensure clean emissions.

- A. Economiser (Feedwater Preheating):

- The Principle: An economiser uses the residual heat from the outgoing flue gases (which would otherwise be wasted) to pre-heat the boiler’s incoming feedwater.

- The Benefit: For every 6 C rise in feedwater temperature, boiler efficiency increases by approximately 1%. This directly translates to less fuel required to bring the water to boiling point, leading to substantial savings.

- B. Air Preheater (APH):

- The Principle: Similar to an economiser, an APH recovers heat from the flue gases to pre-heat the combustion air before it enters the furnace.

- The Benefit: Pre-heated combustion air results in a hotter, more efficient flame, promoting complete combustion and further increasing boiler thermal efficiency. An APH can boost efficiency by 2% – 5% depending on the flue gas temperature drop.

- C. High-Efficiency Multi-Cyclone Dust Collector (MCDC):

- Cleaner Combustion: Husk boilers require effective ash management. A well-designed MCDC, placed after the boiler, efficiently separates fine silica ash particles from the flue gases. This ensures that only cleaner gases are discharged to the atmosphere, complying with strict Pollution Control Board (PCB) norms.

- Valuable Byproduct: The collected ash, primarily silica-rich Rice Husk Ash (RHA), can be a valuable raw material for industries like cement and construction.

The IndianBoilers.com Efficiency Promise: Stable Steam, Lower Costs, Cleaner Future

By meticulously optimizing combustion, maximizing heat transfer, and integrating advanced heat recovery and pollution control systems, IndianBoilers.com ensures our Husk Fired Boilers deliver:

- Stable & Consistent Steam Output: Essential for uninterrupted industrial processes.

- Significantly Lower Fuel Costs: Achieving a thermal efficiency of 78% – 85% (with APH/Economizer) means less husk is needed per tonnes of steam, maximizing your fuel savings.

- Cleaner Emissions: Compliance with environmental regulations and a reduced carbon footprint, aligning your business with a sustainable future.

Choosing an efficient Husk Fired Boiler isn’t just about opting for a cheaper fuel; it’s about investing in a technically superior system that drives down operational costs and elevates your environmental responsibility.

Ready to revolutionize your steam generation with unparalleled efficiency?

Contact IndianBoilers.com today for a detailed consultation and see how our Husk Fired Boilers can transform your operational economics.