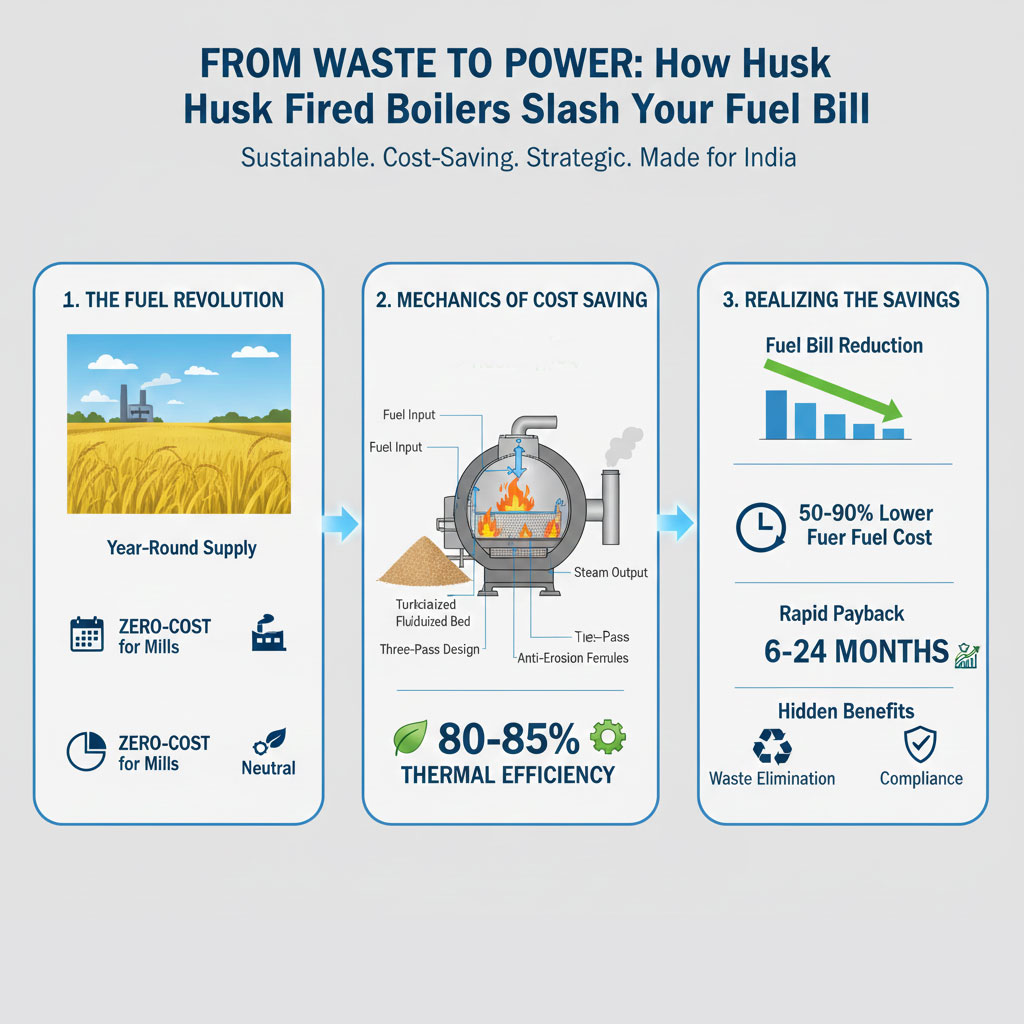

From Waste to Power: How Husk Fired Boilers Slash Your Fuel Bill

In India’s dynamic industrial landscape, the quest for operational efficiency often boils down to one critical factor: fuel cost. Traditional reliance on fossil fuels like coal, diesel, and furnace oil has left many businesses vulnerable to volatile market prices and increasing environmental pressures.

But what if your biggest waste product could become your most valuable energy source? At IndianBoilers.com, we specialize in making this a reality with our advanced Husk Fired Boilers. This isn’t just about burning waste; it’s about transforming agricultural residue into consistent, low-cost steam, fundamentally reshaping your energy economics.

1. The Fuel Revolution: Understanding Husk as a Power Source

The journey from waste to power begins with recognizing the inherent value in rice husk. India produces over 100 million tonnes of rice husk annually, an agricultural byproduct often seen as a disposal problem.

A. The Hidden Energy in Husk

- Abundance & Local Availability: Rice mills across India generate a consistent, year-round supply of husk. For mills, it’s a zero-cost waste product. For other industries, local sourcing means lower transportation costs and a stable supply chain, insulated from international market volatility.

- Carbon Neutrality: Husk is a biomass fuel, meaning the CO2 released during its combustion is equivalent to what the rice plant absorbed during its growth. This makes it a carbon-neutral energy source, helping industries meet their environmental commitments without compromising output.

- Price Stability: Unlike crude oil or international coal markets, local biomass prices are significantly more stable and predictable, allowing for better long-term budgeting and operational security.

B. Why “Waste” is Actually “Wealth”

Consider a typical rice mill. They spend money to dispose of husk or face environmental penalties for improper disposal. By installing a husk-fired boiler, they eliminate disposal costs and convert that waste into free energy. This dual benefit—waste elimination and energy generation—is a powerful economic driver.

2. The Mechanics of Cost Saving: How Husk Boilers Maximize Efficiency

Simply burning husk isn’t enough; the key to cutting your fuel bill lies in advanced boiler design that extracts maximum energy from this unique fuel. IndianBoilers.com specializes in engineering that delivers optimal performance.

A. Specialized Combustion for Low-Cost Fuel

Husk’s low bulk density and high ash content (18%-25% silica) are challenges that traditional boilers cannot handle efficiently. Our Husk Fired Boilers employ specialized combustion technologies:

- Internal Furnace Top Feed Design: For small to medium capacities (0.5 – 6TPH), husk is pneumatically fed from the top into a large, enclosed internal furnace. This ensures sufficient residence time for complete combustion, minimizing unburnt fuel losses. Primary and secondary air supply is meticulously controlled to maximize efficiency and achieve thermal efficiencies of 78% – 80%.

- Fluidized Bed Combustion (FBC) Technology: For larger capacities (4 TPH and above), FBC creates a turbulent bed of inert material (e.g., sand) where husk burns rapidly and completely. This technology handles varying fuel quality exceptionally well and can achieve efficiencies of 80% – 85% or higher.

The Cost-Saving Link: Efficient combustion means every kilogram of husk yields more usable steam, directly reducing the total amount of fuel you need to buy or consume.

B. Maximized Heat Transfer & Recovery

Our boilers are designed to capture every possible unit of heat:

- Three-Pass Design: Flue gases travel through three distinct passes, maximizing contact with the boiler water and transferring more heat.

- Wet Back Design: A fully wet back furnace ensures all surfaces exposed to heat are surrounded by water, minimizing radiation losses—a common efficiency drain in dry back designs.

- Air Preheaters (APH) & Economisers: These optional (but highly recommended) heat recovery units preheat combustion air or feedwater using waste heat from the flue gases, further boosting overall thermal efficiency by $5\%$ – $10\%$.

The Cost-Saving Link: More heat recovery means less fuel is needed to reach the desired steam temperature and pressure.

C. Smart Ash Management for Uninterrupted Operation

Husk’s high silica ash, if not managed correctly, can lead to costly downtime and maintenance. Our designs include:

- High-Efficiency Multi-Cyclone Dust Collectors (MCDC): These capture up to 99% of fly ash particles before they can erode boiler tubes or exit the chimney.

- Anti-Erosion Ferrules: Special protective caps are placed at smoke tube inlets to shield them from the abrasive silica, significantly extending boiler lifespan and reducing maintenance frequency.

- Automatic Ash Removal: This system ensures continuous operation without manual intervention, minimizing labour costs and maximizing boiler uptime.

The Cost-Saving Link: Reduced wear and tear, coupled with automated systems, means lower maintenance costs and higher operational availability, translating directly to continuous production and fewer unexpected expenses.

3. Realizing the Savings: A Rapid ROI for Your Plant

The culmination of these technical advantages is a drastic reduction in your operational expenses and an incredibly fast return on investment.

A. Direct Fuel Bill Reduction

For many Indian industries, switching from coal or diesel to rice husk can reduce fuel costs by 50% to 90%. For a rice mill, the fuel bill can effectively drop to zero.

B. Swift Payback Period

Despite a potentially higher initial capital investment for specialized husk boilers (compared to basic fossil fuel boilers), the overwhelming fuel savings lead to payback periods of often 6 months to 2 years—a return unmatched by most industrial machinery investments.

C. Beyond the Fuel Bill: Hidden Savings & Benefits

- Reduced Waste Disposal Costs: For industries generating husk, eliminate landfill fees or disposal challenges.

- Environmental Compliance: Avoid penalties and gain a “green” advantage, appealing to environmentally conscious consumers and supply chains.

- Energy Security: Rely on a stable, local fuel source rather than unpredictable global markets.

Conclusion: Transform Your Waste, Transform Your Profits

The era of burning expensive, polluting fossil fuels as a primary energy source is drawing to a close. Husk Fired Boilers offer Indian industries a powerful, sustainable, and economically superior alternative. They don’t just reduce your fuel bill; they turn your waste into a consistent, reliable power source, securing your operational costs and positioning your business for a greener, more profitable future.

Ready to unlock the power of your waste and dramatically cut your fuel expenses?

Contact IndianBoilers.com today to explore how a custom-designed Husk Fired Boiler can revolutionize your energy strategy.