Biomass & Husk Fired Boilers: The Future of Industrial Steam in India

The industrial sector in India is at a crossroads. Facing relentless pressure from rising fossil fuel costs, unpredictable global energy markets, and increasingly strict environmental mandates, businesses are mandated to seek new, resilient energy solutions. The answer is already abundant, local, and sustainable: Biomass, particularly Rice Husk.

At IndianBoilers.com, we believe that Biomass Fired Steam Boiler and Husk Fired Boilers are not just an alternative—they represent the definitive future of clean, cost-effective industrial steam generation in India.

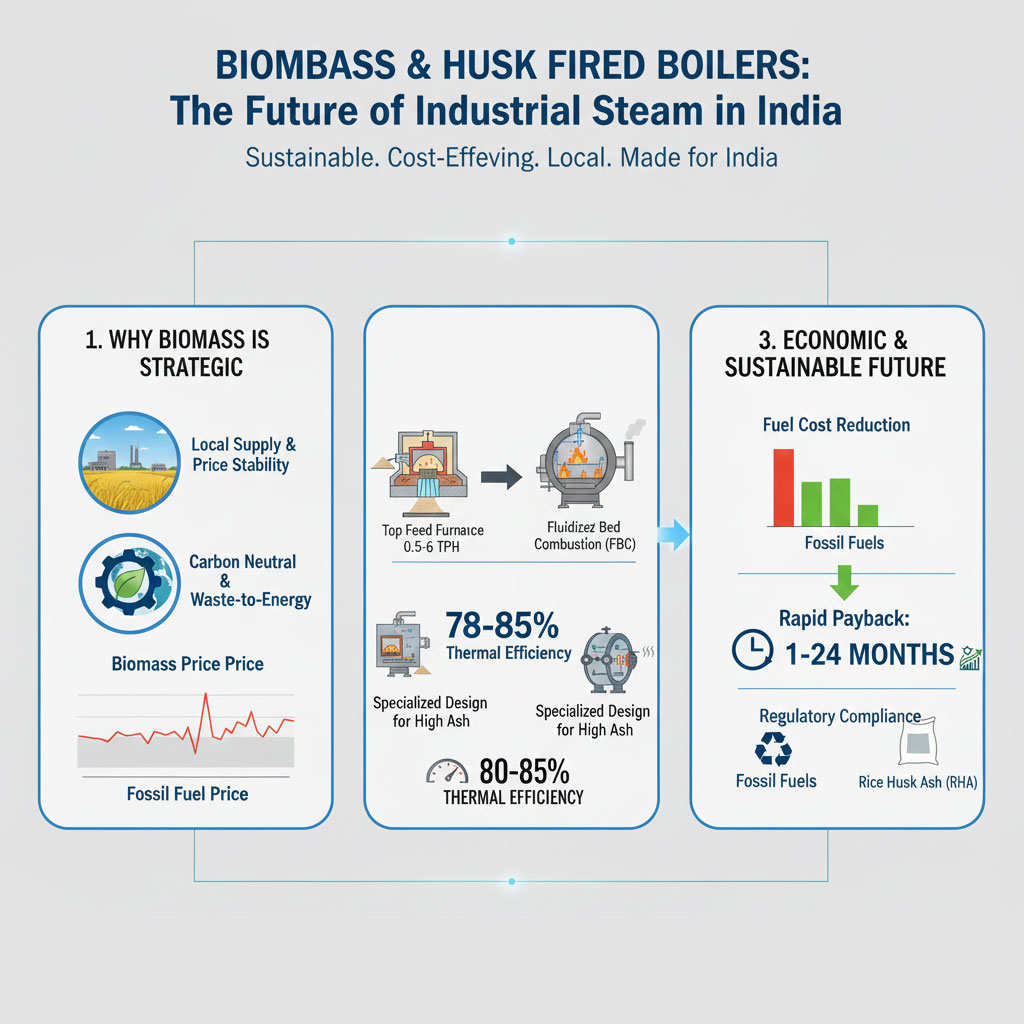

1. Why Biomass is the Strategic Imperative for India

India’s energy demand is immense, and its agricultural output provides a unique solution through biomass. Biomass refers to organic material derived from plants or animals, most commonly agro-residues.

A. Economic Independence and Stability

India’s reliance on imported coal and crude oil exposes its industries to currency fluctuations and geopolitical instability.

- Local Supply Chain: Biomass fuels like rice husk, bagasse, groundnut shells, and wood chips are produced domestically. Utilizing them strengthens local economies, reduces reliance on imports, and keeps energy costs stable.

- Fuel Price Stability: While the price of coal and furnace oil is set internationally, biomass prices are localized and far less volatile. This allows Indian industries to budget with greater certainty and confidence.

B. The Zero-Carbon Advantage

Biomass combustion is considered carbon neutral under most regulatory frameworks, making it a critical tool for fighting climate change.

- Carbon Neutrality: When biomass is burned, it releases the same amount of CO2 that the plants absorbed during their growth. This creates a closed carbon cycle, unlike fossil fuels, which release stored carbon into the atmosphere.

- Waste-to-Energy: Utilizing agro-waste addresses a dual problem: providing clean energy and solving the complex issue of agricultural waste disposal (like stubble burning), leading to a cleaner environment across the Indian subcontinent.

2. Rice Husk: India’s Most Practical Biomass Fuel

While all biomass is valuable, Rice Husk holds a special place in the Indian context due to its unique availability and practicality.

A. Unmatched Availability

As one of the world’s largest rice producers, India ensures a continuous and decentralized supply of husk.

- Continuous Generation: Unlike seasonal biomass (like sugarcane bagasse), rice is processed year-round, offering a non-cyclical, reliable fuel stream.

- Proximity to Industry: Rice mills are widespread, meaning textile units, food processors, and other industries located near agricultural clusters can secure husk cheaply and locally.

B. Engineering for Unique Fuel Challenges

Husk presents specific engineering challenges—namely its low bulk density and high silica ash content. Specialized boiler designs overcome these issues to ensure high efficiency.

| Boiler Technology | Ideal Capacity (TPH) | Key Feature for Husk | Benefit |

| Top Feed/Internal Furnace | Low to Medium (approx 0.5 – 6) | Large furnace volume, pneumatic feeding | Excellent efficiency, compact size, fast ROI. |

| Fluidized Bed Combustion (FBC) | Medium to High (approx 4 +) | Turbulent mixing, fuel flexibility | Handles varying moisture/ash content, highest efficiency, stable operation. |

Boiler Efficiency: Modern Husk Fired Boilers from IndianBoilers.com, incorporating advanced heat recovery (Economisers, Air Preheaters), consistently achieve thermal efficiencies of 78% to 85%, matching or exceeding many conventional coal boilers.

3. The Economic Case: Cost Savings and ROI

The ultimate driver for adopting Biomass and Husk Fired Boilers is the overwhelming financial benefit, which translates into rapid payback periods.

A. Cutting the Fuel Bill

The fuel cost component in a Husk Fired Boiler can be as low as one-fifth of a coal boiler and a fraction of a diesel-fired unit.

- Near-Zero Cost for Rice Mills: For these units, the conversion is often purely beneficial, eliminating waste disposal costs and external fuel purchases entirely.

- Fastest Payback: Due to massive annual fuel savings, the additional capital cost required for the specialized biomass boiler and handling equipment is often recovered in 1 to 2 years, a crucial metric for any industrial CFO.

B. High Value Ash Byproduct

Unlike coal ash, the resulting Rice Husk Ash (RHA) is highly valuable, being predominantly silica ($\text{SiO}_2$).

- Industrial Use: RHA is sought after by the cement, refractory, and construction industries. This creates an additional revenue stream, further offsetting operational costs and eliminating a disposal liability.

4. The Future is Green, Local, and Profitable

The transition to Biomass and Husk Fired Boilers is not a passing trend; it is a structural shift necessary for the sustained success of Indian industry.

- Regulatory Alignment: As government policy favors renewable energy and tightens emission standards, these boilers future-proof your investment, ensuring long-term compliance without expensive retrofits.

- Corporate Responsibility: Using local biomass enhances your company’s image as an environmentally and socially responsible entity, essential for securing business from multinational clients.

Biomass is the decentralized, abundant, and economically powerful fuel that India needs. By investing in a high-efficiency Husk Fired Boiler, your industry takes a decisive step towards lower operating costs, greater energy security, and a cleaner footprint.

Secure your energy future today.

Contact IndianBoilers.com to understand how our expert-engineered Biomass Fired Boiler and Husk Fired Boilers can power your transition to the next generation of industrial steam.