The industrial landscape in India is undergoing a profound transformation. As we move through 2026, the traditional reliance on volatile fossil fuels like furnace oil and coal is becoming a financial and regulatory liability. For modern factory owners, the “Green Transition” is no longer a buzzword—it is a strategic pivot to protect the bottom line.

At IndianBoilers.com, we are at the forefront of this shift. Our engineering philosophy is simple: Waste is not a problem; it is a fuel. By utilizing agricultural residues, wood waste, and industrial by-products, factories can achieve energy independence. This guide breaks down the financial and environmental ROI of switching to biomass, featuring our specialized lineup: COMCUBE, STEAMAX, VTFH-SERIES, AQUAMAX, and AIRMAX.

1. The 2026 Energy Landscape: Why Fossil Fuels are Failing

For decades, the standard choice for steam or heat was Furnace Oil (FO) or Light Diesel Oil (LDO). However, several factors have made these “dirty” fuels obsolete for competitive manufacturing:

- Price Volatility: Fossil fuel prices are sensitive to global geopolitical tensions, making long-term operational budgeting impossible.

- Carbon Taxation: With the introduction of the Carbon Border Adjustment Mechanism (CBAM) and domestic carbon credit markets, high-emission factories are facing direct financial penalties.

- Emission Norms: The CAQM (Commission for Air Quality Management) and CPCB have set strict particulate matter (PM) limits. Industries in the NCR and beyond are now mandated to switch to cleaner fuels or face closure.

The Biomass Advantage

Biomass is considered carbon-neutral. The $CO_2$ released during combustion is the same amount the plant absorbed during its growth, creating a closed-loop cycle. In India, where agricultural waste is abundant, biomass fuels like rice husk or briquettes cost a fraction of imported oil.

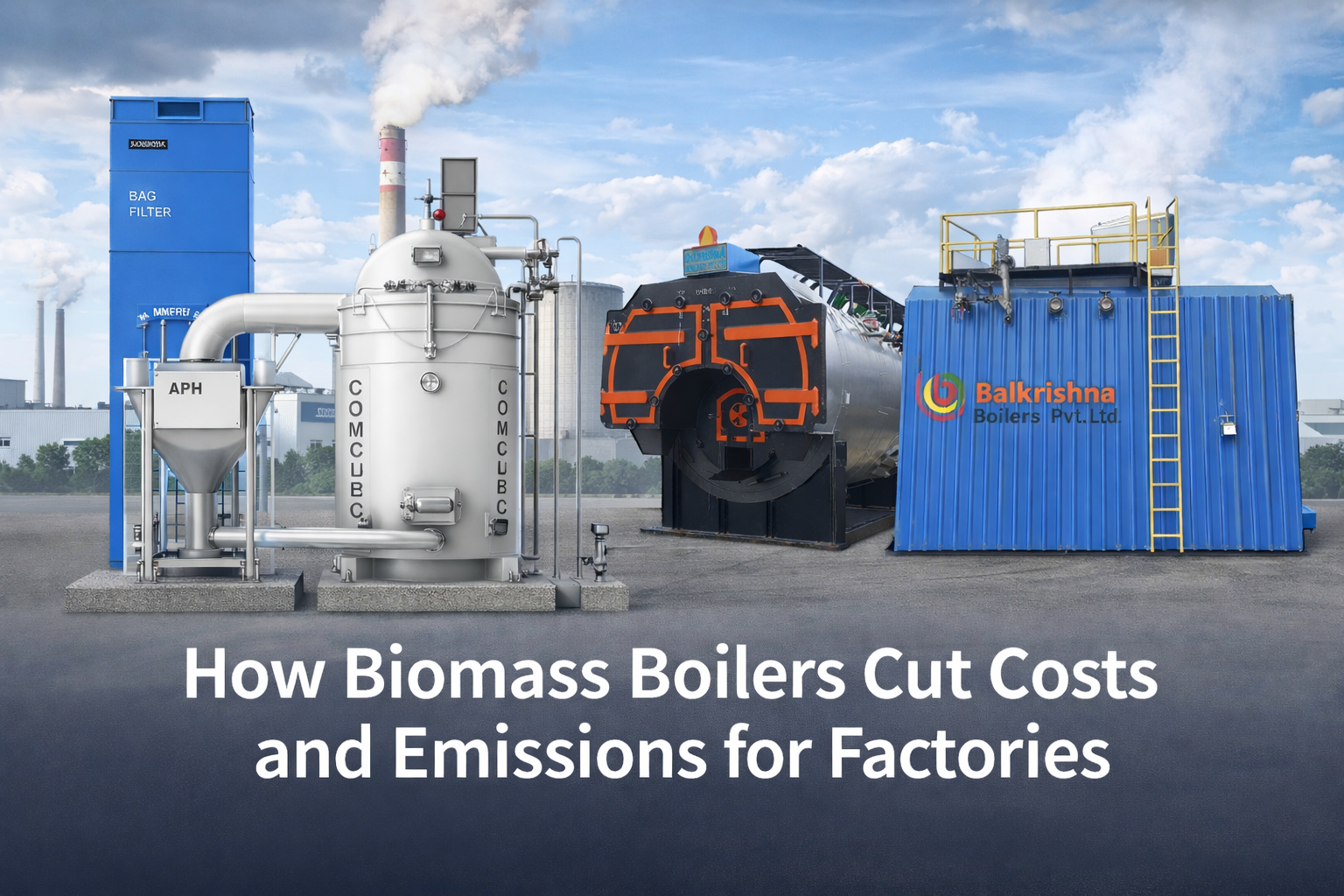

2. Revolutionary Steam Solutions: COMCUBE & STEAMAX

Steam is the primary energy carrier for industries like textiles, pharmaceuticals, and chemicals. Our steam series is designed to maximize extraction from every kilogram of biomass.

COMCUBE – Biomass Fired Steam Boiler

The COMCUBE is our answer to the “Space vs. Power” dilemma. Traditionally, biomass boilers required massive footprints.

- The Innovation: A compact, modular “cube” design that fits into tight factory layouts.

- Efficiency: Features advanced furnace geometry that ensures high turbulence and complete combustion of biomass pellets or crushed briquettes.

- Best For: Small to medium-scale manufacturing units needing rapid steam generation with minimal civil work.

STEAMAX – Briquette Fired Steam Boiler

When your process requires high-volume, consistent steam, the STEAMAX is the industrial workhorse.

- Fuel Strategy: Optimized specifically for biomass briquettes, which offer higher energy density and easier storage than loose biomass.

- Operational Stability: Its large water-holding capacity acts as a thermal buffer, absorbing sudden load fluctuations common in batch processing.

- Automation: Equipped with an automated fuel feeding system, reducing human error and ensuring a steady steam pressure profile.

3. Specialized Heating: VTFH-SERIES & AQUAMAX

Many industrial processes require hot water or thermic fluids rather than steam. For these applications, efficiency is found in precision.

VTFH-SERIES – Biomass Fired Water Boiler

The VTFH-SERIES is a Vertical Four-Pass Smoke Tube design. It is specifically engineered for facilities where hot water is the primary medium for heat transfer.

- Maximum Heat Recovery: The four-pass design ensures that the flue gases spend more time in the heat exchanger, resulting in very low stack temperatures and higher efficiency.

- Safety: Since it operates as a water boiler, the risks associated with high-pressure steam are eliminated, making it ideal for laundry, hospitality, and dairy sectors.

AQUAMAX – Briquette Fired Water Boiler

The AQUAMAX is designed for “Continuous Hot Water Supply.” In 2026, where energy recovery is key, AQUAMAX leads the pack.

- High Thermal Efficiency: Achieves over 80% efficiency on NCV (Net Calorific Value).

- Rugged Design: Built to handle the varying water qualities found in Indian industrial zones, requiring significantly less maintenance than sensitive imported units.

- User-Friendly: Simple controls allow even semi-skilled staff to manage the unit safely.

4. Revolutionizing Drying: The AIRMAX Generator

In sectors like food dehydration, chemical powder processing, and ceramics, the requirement isn’t for steam or water—it’s for clean, hot air.

AIRMAX – Briquette Fired Air Generator

The AIRMAX is an indirect-fired system, meaning the combustion gases never touch the process air.

- Contamination-Free: Essential for the food and pharma industries where any trace of smoke or ash would ruin the product.

- Cost Savings: Generating hot air using biomass briquettes is up to 60% cheaper than using electrical heaters or diesel-fired air generators.

- Temperature Range: Capable of delivering air at temperatures up to 300°C with precise modulation.

5. The ROI Math: A 2026 Case Study

Consider a textile dyeing unit in Ludhiana or a food plant in Gujarat currently using LDO for a 2-ton steam load.

| Feature | Fossil Fuel (LDO) | Biomass (STEAMAX / COMCUBE) |

| Fuel Price (Approx) | ₹85 / Liter | ₹10 / Kg |

| CV (kcal) | 10,200 | 3,800 – 4,200 |

| Fuel Required per Hour | ~140 Liters | ~400 Kg |

| Hourly Cost | ₹11,900 | ₹4,000 |

| Annual Savings (20h/day) | Baseline | ₹5,60,00,000+ |

In most industrial cases, the Payback Period for a new IndianBoilers.com biomass system is between 6 to 12 months. After the first year, the savings contribute directly to your EBITDA.

6. Regulatory Compliance & Environmental Stewardship

The 2026 standards for PM (Particulate Matter) are non-negotiable. All our series—COMCUBE, STEAMAX, VTFH, AQUAMAX, and AIRMAX—come integrated with:

- Multi-Cyclone Dust Collectors: To capture heavy ash particles.

- Bag Filters: To ensure the final chimney discharge is clear and meets the < 50 mg/Nm³ norms.

- Star Labeling Compatibility: Our boilers are designed to meet the BEE (Bureau of Energy Efficiency) star-rating bands, ensuring you are buying the most efficient tech available in India.

Conclusion: Future-Proof Your Factory

The question is no longer whether you should switch to biomass, but how quickly you can do it. With the IndianBoilers.com suite of products, you aren’t just buying equipment; you are investing in a low-cost, low-carbon future.

- Need compact steam? Go for COMCUBE.

- Need heavy-duty briquette firing? Choose STEAMAX.

- Process requires hot water? Select VTFH or AQUAMAX.

- Drying is your priority? AIRMAX is your solution.

Ready to see a detailed technical proposal for your site?

Would you like me to prepare a fuel-cost comparison report based on your specific local fuel prices (e.g., Rice Husk vs. Sawdust Briquettes)?