Unlocking Green Energy: Why Biomass Boilers are the Future of Indian Food Processing

The food processing industry in India is at a crossroads. As one of the largest sectors in the country, it is the backbone of the economy, yet it faces a dual challenge: the skyrocketing cost of fossil fuels and the urgent pressure to reduce carbon footprints. For facilities ranging from dairy plants and rice mills to dehydrators and beverage units, steam is the lifeblood of production.

At IndianBoilers.com, we recognize that “going green” isn’t just about corporate social responsibility—it’s about operational survival. In 2026, the transition to biomass isn’t just an alternative; it is the most viable path to energy independence.

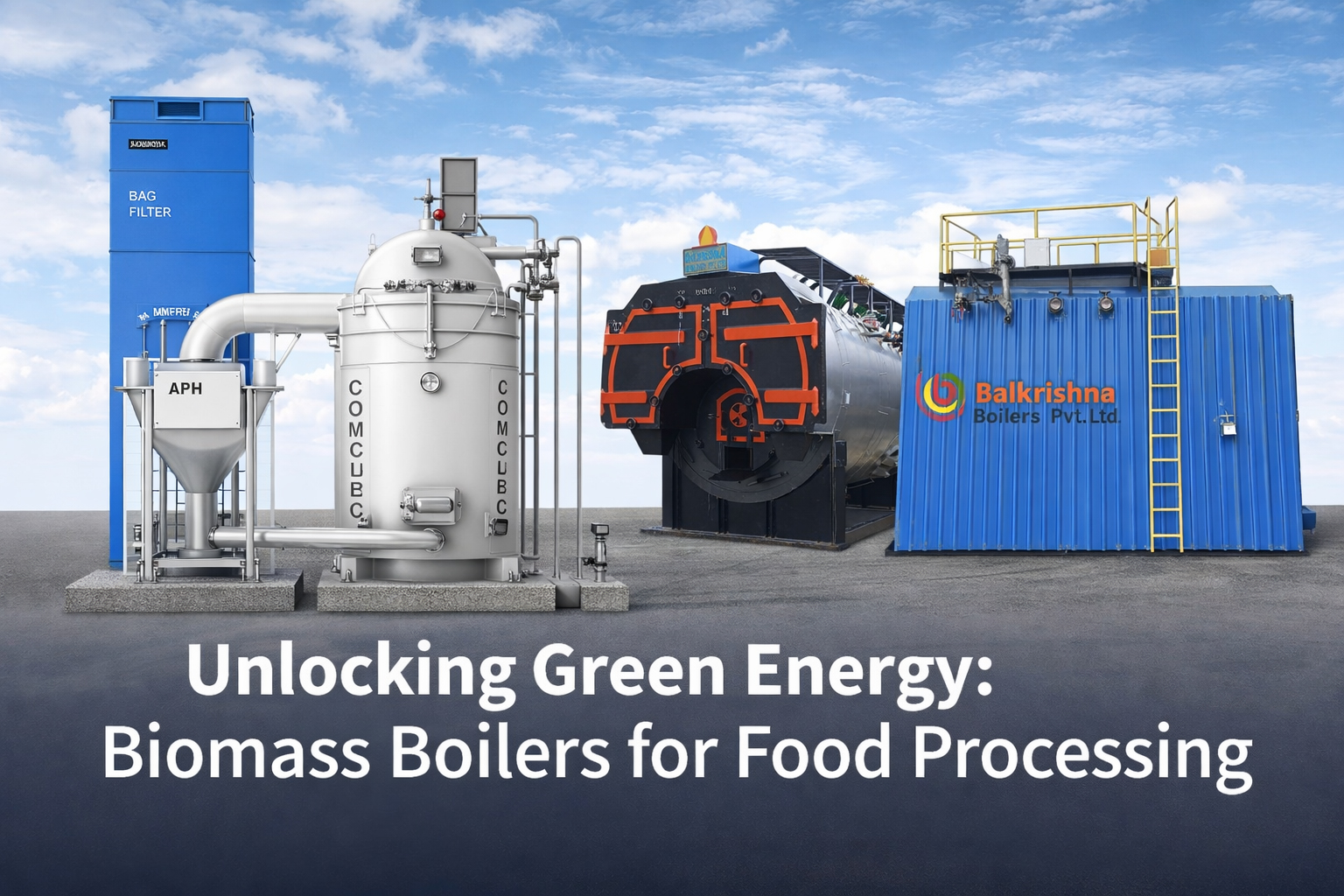

This comprehensive guide explores how our specialized range—including the COMCUBE, STEAMAX, VTFH-SERIES, AQUAMAX, and AIRMAX—is revolutionizing the food processing landscape.

1. The Energy Crisis in Food Processing

Food processing is inherently energy-intensive. Whether you are pasteurizing milk, drying grains, or sterilizing cans, the requirement for high-quality, consistent heat is non-negotiable. Traditionally, this has been powered by Furnace Oil (FO), Light Diesel Oil (LDO), or Coal.

The Problem with Status Quo:

- Price Instability: Fossil fuel prices are tied to global geopolitical shifts, making long-term budgeting nearly impossible.

- Regulatory Scrutiny: The CPCB and state-level boards are tightening emission norms. Older coal-fired units are finding it harder to get their Consents to Operate (CTO).

- Carbon Border Taxes: For exporters, the carbon intensity of your manufacturing process now affects your ability to compete in international markets like the EU.

The Biomass Solution:

Biomass (briquettes, pellets, agricultural waste) is carbon-neutral because the $CO_2$ released during combustion is equal to the $CO_2$ absorbed by the plant during its growth. For an Indian manufacturer, biomass is a local, renewable, and decentralized fuel source.

2. High-Efficiency Steam Solutions: COMCUBE & STEAMAX

Steam is the primary medium for heat transfer in food plants. We have engineered two flagship models to handle the unique demands of this sector.

COMCUBE: The Biomass Fired Steam Boiler

The COMCUBE – Biomass Fired Steam Boiler is designed for the modern factory where space is at a premium but demand is high.

- Compact Design: Its “cube” configuration allows for a smaller footprint without sacrificing thermal output.

- High Efficiency: Utilizing advanced furnace geometry, the COMCUBE ensures that every gram of biomass is converted into usable energy.

- Applications: Ideal for small-to-medium scale bakeries, confectionery units, and spice processing plants.

STEAMAX: The Briquette Fired Steam Boiler

For larger industrial loads, the STEAMAX – Briquette Fired Steam Boiler is the workhorse of the industry.

- Fuel Versatility: Optimized specifically for briquettes, which offer higher bulk density and easier storage than raw biomass.

- Steady Pressure: Food processing requires precise pressure control to ensure food safety and quality. STEAMAX provides a steady steam profile even during peak loads.

- Durability: Built with high-grade boiler steel to withstand the rigors of 24/7 operations.

3. Specialized Heating: VTFH-SERIES & AQUAMAX

Not every process requires steam. Many food applications, such as large-scale frying, oil heating, or hot water washing, require specialized water heating systems.

VTFH-SERIES: Biomass Fired Water Boiler

The VTFH-SERIES – Biomass Fired Water Boiler is a Vertical Thermic Fluid Heater/Water Boiler designed for high-temperature applications without the high pressure associated with steam.

- Safety First: By using water or thermic fluids as a medium, the system operates at lower pressures, reducing the risks associated with high-pressure steam in sensitive environments.

- Precision Control: Essential for processes like chocolate tempering or edible oil refining.

AQUAMAX: Briquette Fired Water Boiler

For facilities that require massive volumes of hot water—such as industrial dairies for CIP (Cleaning In Place) or slaughterhouses—the AQUAMAX – Briquette Fired Water Boiler is the go-to solution.

- Rapid Heating: AQUAMAX is designed for quick startup times, ensuring that your cleaning cycles aren’t delayed.

- Low Maintenance: Its robust design handles the mineral content of industrial water supplies better than sensitive steam systems.

4. Revolutionizing Drying: The AIRMAX Air Generator

In the world of dehydration—think dried fruits, tea, coffee, and herbs—the quality of air is paramount.

AIRMAX: Briquette Fired Air Generator

The AIRMAX – Briquette Fired Air Generator provides clean, hot air for drying processes without the risk of contamination.

- Indirect Heating: Unlike direct-fired systems that might taint food products with smoke or ash, AIRMAX uses high-efficiency heat exchangers.

- Uniform Drying: Consistent air temperature ensures that the food product dries evenly, preserving nutritional value and color.

5. Financial Impact: The ROI of Switching

Let’s look at a hypothetical scenario for a mid-sized fruit pulp processing unit in Maharashtra.

| Factor | Fossil Fuel (LDO) | Biomass (STEAMAX) |

| Fuel Cost (per kg/L) | ₹75 – ₹90 | ₹8 – ₹12 |

| Calorific Value | ~10,000 kcal | ~3,500 – 4,000 kcal |

| Daily Fuel Cost | ₹1,50,000 | ₹65,000 |

| Monthly Savings | – | ₹25,50,000 |

In this scenario, the capital expenditure for an IndianBoilers.com system is often recovered within 8 to 14 months. Post-payback, the reduction in operating costs directly increases the profit margin per unit of food produced.

6. Engineering Excellence & Compliance

At IndianBoilers.com, we don’t just provide a vessel; we provide a system. Our boilers are equipped with:

- Pollution Control: Integrated Cyclomax separators and Bag Filters to meet the strictest environmental norms.

- Automation: PLC-based control panels that allow your operators to monitor efficiency in real-time.

- Safety Interlocks: High-pressure cut-offs, low-water alarms, and flame sensors to ensure your staff remains safe.

Conclusion: Lead the Change

The Indian food processing sector is set to grow exponentially by 2030. To be a part of that growth, your facility must be efficient, compliant, and sustainable. By choosing the COMCUBE, STEAMAX, VTFH-SERIES, AQUAMAX, or AIRMAX, you are not just buying a boiler—you are securing the future of your business.