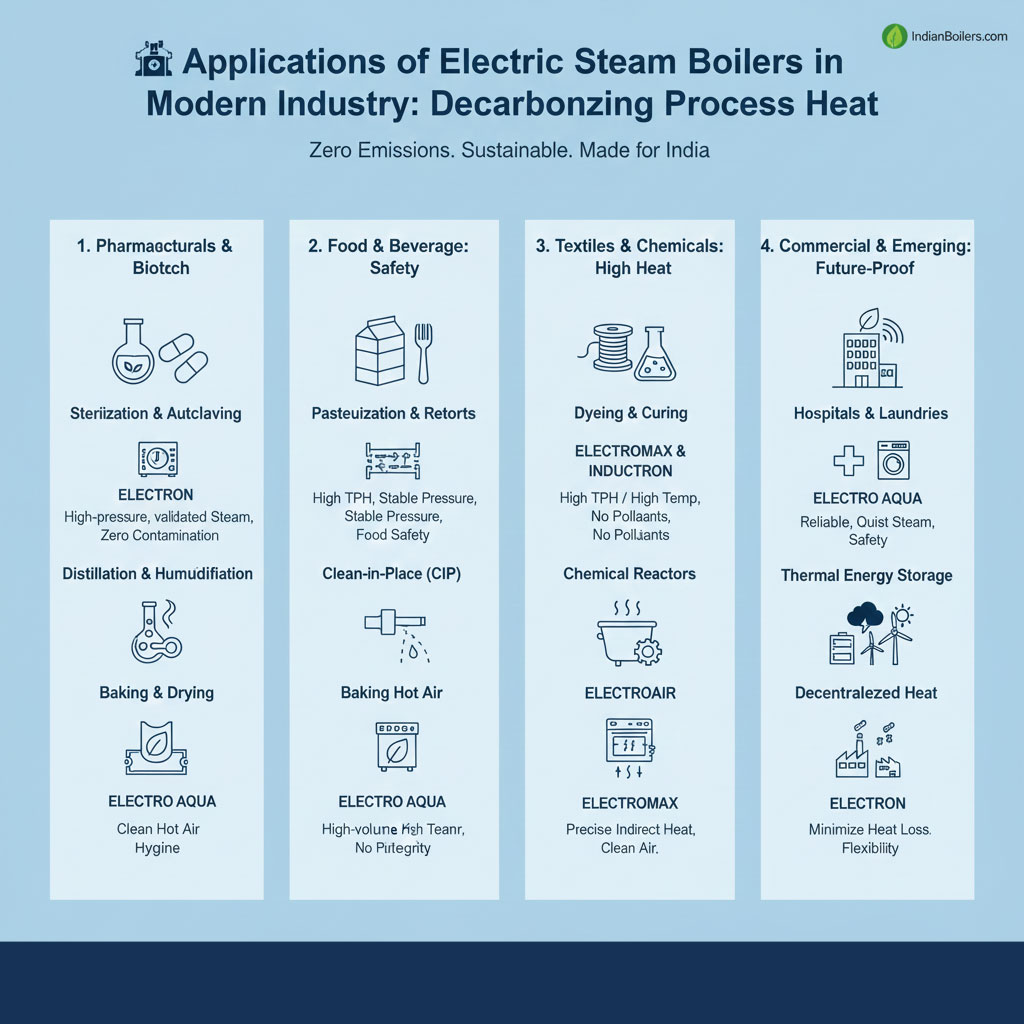

Applications of Electric Steam Boilers in Modern Industry: Decarbonizing Process Heat

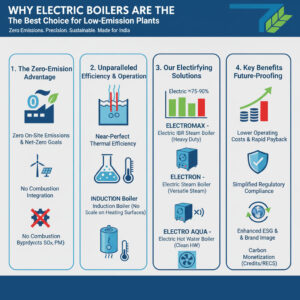

The global energy transition is reshaping industrial infrastructure. As organizations commit to net-zero targets and face tightening environmental regulations, the need for clean, reliable, and efficient process heating has never been more urgent. At the heart of this shift lies the Electric Boiler—a zero on-site emission solution that is rapidly replacing traditional fossil fuel combustion systems across virtually every sector.

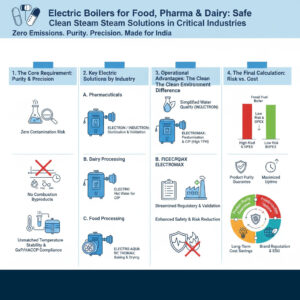

Electric boilers offer a unique combination of performance benefits: 99.5% thermal efficiency, precise temperature control, superior safety, and zero local air pollution. These attributes make them ideal for modern manufacturing, particularly in industries where steam purity and regulatory compliance are paramount.

At IndianBoilers.com, we provide a comprehensive range of electric heating technologies to meet these diverse needs: the compact and versatile ELECTRON – Electric Steam Boiler, the high-capacity, IBR-compliant ELECTROMAX – Electric IBR Steam Boiler, the advanced INDUCTRON – Induction Boiler, and specialized systems like the ELECTROPAC – Electric Thermic Fluid Heater, ELECTRO AQUA – Electric Hot Water Boiler, and ELECTROAIR – Electric Hot Air Generator.

This guide explores the specific and expanding applications of electric steam and heat solutions in modern industry.

1. Pharmaceuticals and Biotech: The Purity Imperative

In pharmaceutical and biotech manufacturing, steam is often categorized as a critical utility, directly impacting product safety and efficacy. Steam must be clean, stable, and delivered without risk of contamination.

A. Sterilization and Autoclaving (ELECTRON & INDUCTRON)

- Requirement: High-pressure, saturated steam is essential for sterilizing equipment (e.g., fermenters, piping, filters) and products in autoclaves. Sterilization processes must be validated, demanding absolute consistency in temperature and pressure.

- Electric Solution: The compact ELECTRON is perfectly suited for decentralized installation near the point of use (POU), like a laboratory or a cluster of autoclaves. This minimizes piping, reducing heat loss and the risk of condensate contamination. The INDUCTRON offers an even higher level of assurance with its scale-resistant core, guaranteeing sustained performance for validated processes.

- Why Electric is Preferred: The absence of combustion means there is zero risk of burner fumes, soot, or fuel leaks contaminating clean rooms or adjacent air intakes. The precise electronic control ensures easy validation and compliance with strict regulatory protocols.

B. Distillation and Humidification (ELECTRON)

- Requirement: Clean steam is used in Multiple Effect Water Stills for producing Water for Injection (WFI), which requires consistent temperature input. Low-pressure steam is also used for humidifying sterile environments.

- Electric Solution: Low-to-medium capacity ELECTRON boilers are installed to provide process steam or clean steam (generated using purified water) for these sensitive tasks, ensuring that the critical utility input is as pure and reliable as the output.

2. Food and Beverage Processing: Safety and Flavor Integrity

The food and beverage industry utilizes steam for cooking, pasteurization, sterilization, and cleaning. Here, the focus is on food safety, precise cooking/holding temperatures, and preventing off-flavors.

A. Pasteurization and Retort Cooking (ELECTROMAX & INDUCTRON)

- Requirement: Large volumes of reliable, high-pressure steam are needed for continuous processes like High-Temperature Short-Time (HTST) pasteurization in dairy and beverage plants, or for batch sterilization in retorts (canning).

- Electric Solution: The robust, IBR-compliant ELECTROMAX – Electric IBR Steam Boiler is deployed for high-volume, continuous duty. It provides the sustained high pressure necessary to maintain production throughput. For plants prioritizing longevity and minimizing water-side maintenance, the INDUCTRON offers an excellent alternative, resisting scale buildup on the heating surface.

- Why Electric is Preferred: Electric heat ensures highly consistent temperature control, essential for guaranteeing microbial kill-rates (Food Safety). Crucially, the ELECTROAIR – Electric Hot Air Generator can be used in baking or drying processes, providing clean hot air without combustion products (NOx or SOx) that could impart unwanted flavors or odors to the final product.

B. Clean-in-Place (CIP) and Washdown (ELECTRO AQUA)

- Requirement: Large volumes of hot water (approx 80℃ to 95℃) are needed for effective cleaning and sanitation of tanks and piping.

- Electric Solution: The ELECTRO AQUA – Electric Hot Water Boiler provides instant, high-volume hot water efficiently and safely, supporting strict hygiene standards in dairies and breweries without relying on combustion systems.

3. Textiles and Chemicals: High-Temperature and Thermal Fluid Applications

In heavy industries, the demand is often for high heat, whether in the form of steam or specialized thermal fluid. Efficiency and operational simplicity are key.

A. Dyeing, Curing, and Sizing (ELECTROMAX & ELECTROPAC)

- Requirement: Textile dyeing requires large, cyclical steam loads for heating dye baths. Finishing processes often require high, consistent heat, sometimes above the safe pressure limits of steam.

- Electric Solution:

- Steam Load: The ELECTROMAX handles the massive, cyclical steam demands of dye houses with its high-capacity design.

- High Temperature: Where temperatures up to 300 ℃ are needed (e.g., heat setting, curing), the ELECTROPAC – Electric Thermic Fluid Heater is used. This system provides precise, flameless, high-temperature heat transfer without the extreme pressures associated with high-temperature steam.

- Why Electric is Preferred: Electric systems eliminate the need for storing hazardous and polluting fuels (like furnace oil) often used in these sectors, improving the environmental profile of the plant.

B. Chemical Reactors and Polymer Processing (ELECTROPAC)

- Requirement: Precise, high-temperature, indirect heat is needed for maintaining reaction kinetics or melting/forming polymers.

- Electric Solution: ELECTROPAC is the ideal solution for jacketed chemical reactors. Its flameless operation ensures safety, and its ability to maintain high temperature stability is critical for producing on-spec chemical products.

4. Commercial and Institutional: Reliability and Cleanliness

Hospitals, hotels, universities, and commercial laundries have steam and hot water needs focused on immediate availability, space efficiency, and low-noise operation.

A. Hospital Sterilization and Heating (ELECTRON)

- Requirement: Absolute reliability for sterilization steam, instant hot water for patient care, and a quiet, zero-emission operation.

- Electric Solution: ELECTRON boilers are frequently used in hospitals for their quiet operation and ability to be placed closer to surgical suites or kitchens for rapid steam delivery. The ELECTRO AQUA provides instant, high-volume hot water for laundry and sanitation.

- Why Electric is Preferred: Zero NOx emissions are crucial for maintaining clean air in patient-sensitive environments, and the low noise profile minimizes disruption.

B. Commercial Laundries (ELECTRON / ELECTROMAX)

- Requirement: Continuous, high-volume, medium-pressure steam for pressing and drying cycles.

- Electric Solution: Depending on size, either the ELECTRON (for small to medium laundries) or the ELECTROMAX (for large commercial facilities) provides a robust, low-maintenance steam source.

5. Emerging Applications: Grid Balancing and Decarbonization

The role of electric boilers is expanding beyond basic process heating into grid-level energy management.

A. Thermal Energy Storage (Grid Flexibility)

- Requirement: As renewable energy sources (solar and wind) generate excess power at certain times, utilities need systems that can absorb this surplus energy.

- Electric Solution: Large ELECTROMAX boilers can be strategically operated during off-peak or high-renewable-generation periods, generating and storing steam/hot water in large insulated accumulators. The stored thermal energy is then used during peak demand periods, effectively using the boiler as a giant thermal battery to stabilize the grid.

B. Decentralized Heat Generation

- Requirement: Moving away from large, inefficient central boiler rooms.

- Electric Solution: Small, efficient ELECTRON units are installed strategically across a large campus or plant floor, reducing steam piping length, minimizing distribution losses (often 10-20% in large networks), and ensuring that high-quality steam is produced exactly where it is consumed.

Conclusion: Electric Powering the Sustainable Future

The shift to electric steam and heat is a necessary step for industries prioritizing sustainability, operational excellence, and regulatory compliance. The benefits—near 100% efficiency, zero on-site emissions, and unparalleled control—make the technology non-negotiable for critical sectors like Pharma and Food.

IndianBoilers.com is committed to empowering this transition with a tailor-made electric heating solution for every application. Whether your need is the validated purity of the INDUCTRON, the high-pressure capacity of the ELECTROMAX, or the clean-air delivery of the ELECTROAIR, electric technology offers a guaranteed path to a cleaner, safer, and more efficient future.

Are you ready to optimize your process and achieve your net-zero goals?

Contact IndianBoilers.com today for an application-specific consultation to electrify your industrial heating process.