Choosing the correct boiler capacity is the most critical decision in any steam or heat generation project. An undersized boiler cripples production, while an oversized one wastes capital and operates inefficiently. This decision is even more nuanced with Biomass Fired Boilers, where fuel characteristics, operating hours, and process demand variability must be factored in.

At IndianBoilers.com, we guide Indian industries through this essential calculation. Whether you need the high efficiency of the HUSKPOWER – Rice Husk Fired Steam Boiler, the versatility of the COMCUBE – Biomass Steam Boiler, or the reliable heat from the VTFH-SERIES – Biomass Fired Hot Water Boiler, understanding your demand is the first step.

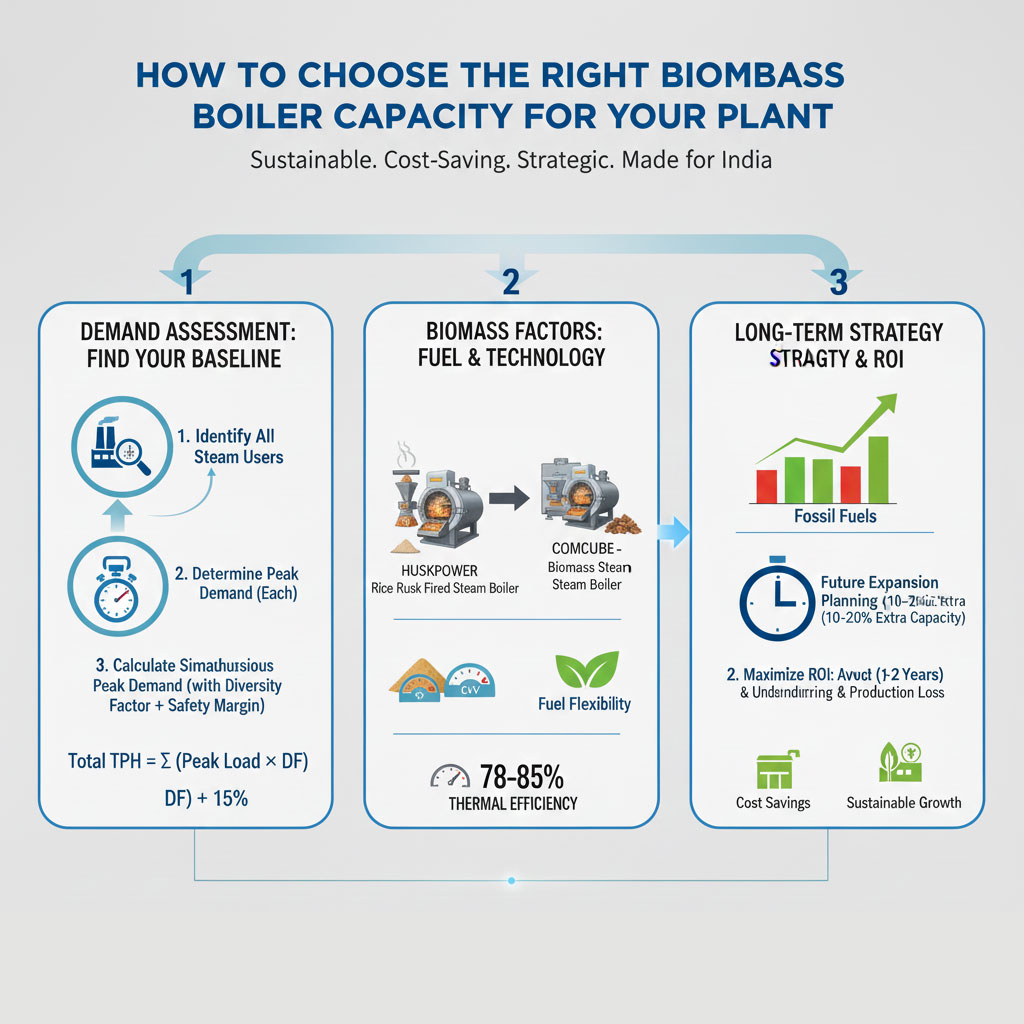

1. Step-by-Step Demand Assessment: Finding Your Steam Baseline

The capacity of a boiler is typically measured in Tonnes of Steam per Hour (TPH) or kcal/hr for hot water/thermic fluid systems. The goal is to determine the maximum steam required by all users simultaneously.

A. Identify All Steam/Heat Consumers

List every piece of equipment that uses steam or hot water in your plant (e.g., dyeing machines, reactors, vulcanizers, dryers, sterilizers, turbines).

B. Determine Peak Demand for Each Consumer

This is the maximum steam or heat rate required by each consumer during its operation. This data is usually available on the equipment’s specifications plate or instruction manual.

- Example: A 500 kg capacity dyeing machine might require 1,000 kg/hr of steam during the initial heating phase.

C. Calculate Simultaneous Peak Demand

This is the crucial step. The maximum boiler capacity must meet the highest instantaneous demand when all major equipment is running.

Diversity Factor: Since it is highly unlikely that every machine will demand peak steam at the exact same moment, a Diversity Factor (DF) is applied. This factor, typically between 0.6 and 0.9 (or 60%-90%), accounts for staggered operation.

- Safety Margin: Always add a safety margin of 10%-15% to the total calculated peak load to handle unexpected requirements, steam leaks, or future expansion.

2. Factoring in Biomass Characteristics: Fuel Flexibility and Efficiency

Once the theoretical TPH is established, the fuel you choose (e.g., rice husk, bagasse, wood chips) and the boiler type must be considered, as they affect practical output.

A. Boiler Type and Fuel Suitability

The choice of boiler type depends on the fuel and the required output:

| Product | Type of Output | Ideal Fuel(s) | Typical Capacity Range (TPH) |

| HUSKPOWER | Husk Steam Boiler | Rice Husk (Primary) | 1 TPH up to 20 TPH |

| COMCUBE | Biomass Steam Boiler | Wood Chips, Bagasse, Pellets | 0.5 TPH up to 4 TPH |

| VTFH-SERIES | Biomass Hot Water Boiler | Multiple Agro-Waste (e.g., Wood, Shells) | 1 Lac kcal/hr up to 60 Lac kcal/hr |

The HUSKPOWER, with its FBC technology, is indispensable for high-ash fuels like rice husk, ensuring consistent output where other boiler types would fail.

B. Fuel Calorific Value (CV)

Biomass fuels have lower CV and higher moisture content than fossil fuels.

- Impact: A lower CV means you need to burn more fuel to generate the same amount of heat. The chosen boiler must have an appropriately sized furnace and combustion system to handle the larger volume of biomass required.

C. Steam Purity and Pressure Requirements

- Pressure: Determine the maximum pressure needed by your highest-pressure consumer (e.g., turbines). Our boilers are custom-designed to meet these exact needs.

- Purity: Applications like food processing or pharmaceuticals require high-purity steam. The capacity and design must support necessary water treatment and blowdown rates without compromising output.

3. Long-Term Strategy: Expansion and ROI

Selecting capacity is also a long-term strategic decision affecting future growth and financial performance.

A. Future Expansion Planning

It is often more cost-effective in the long run to install a boiler with a 10%-20% excess capacity than to replace an undersized unit after just a few years of growth. Discuss your 5-year and 10-year growth plans with our engineers to future-proof your investment.

B. Calculating ROI with Proper Sizing

An accurately sized biomass boiler maximizes cost savings:

- Oversized: Leads to frequent stop-starts, which reduces efficiency, causes thermal stresses, and increases maintenance costs.

- Undersized: Requires expensive fossil-fuel boilers to be run as backups or limits production, negating the biomass cost advantage.

A correctly sized HUSKPOWER or COMCUBE boiler operates consistently at its optimum efficiency point, ensuring the rapid payback driven by fuel savings is fully realized.

4. Let the Experts at IndianBoilers.com Guide You

Determining the precise capacity and selecting the right technology—be it a specialized HUSKPOWER system for rice husk, a versatile COMCUBE steam boiler, or a robust VTFH-SERIES hot water boiler—requires professional expertise.

Our engineers use detailed process flow analysis, fuel testing, and thermodynamic calculations to ensure the boiler selected is perfectly matched to your plant’s present and future needs.

Don’t guess your capacity. Guarantee your efficiency.

Contact IndianBoilers.com today for a comprehensive, free steam demand audit and expert guidance on selecting the ideal biomass boiler for your factory.