Reduce Carbon Emissions with Biomass Fired Steam Boilers in 2025

The year 2025 marks a critical threshold for industrial sustainability in India. As national and global pressure mounts to meet ambitious carbon reduction goals, industries powered by fossil fuels face increasing regulatory scrutiny and operational risk. The mandate is clear: switch to cleaner energy or fall behind.

At IndianBoilers.com, we provide the solution. Our advanced Biomass Fired Boilers ingeniously transform abundant agricultural waste—such as rice husk, bagasse, and wood chips—into reliable, high-efficiency steam power. This is more than a cost-saving measure; it is a decisive move to achieve carbon neutrality and future-proof your factory operations.

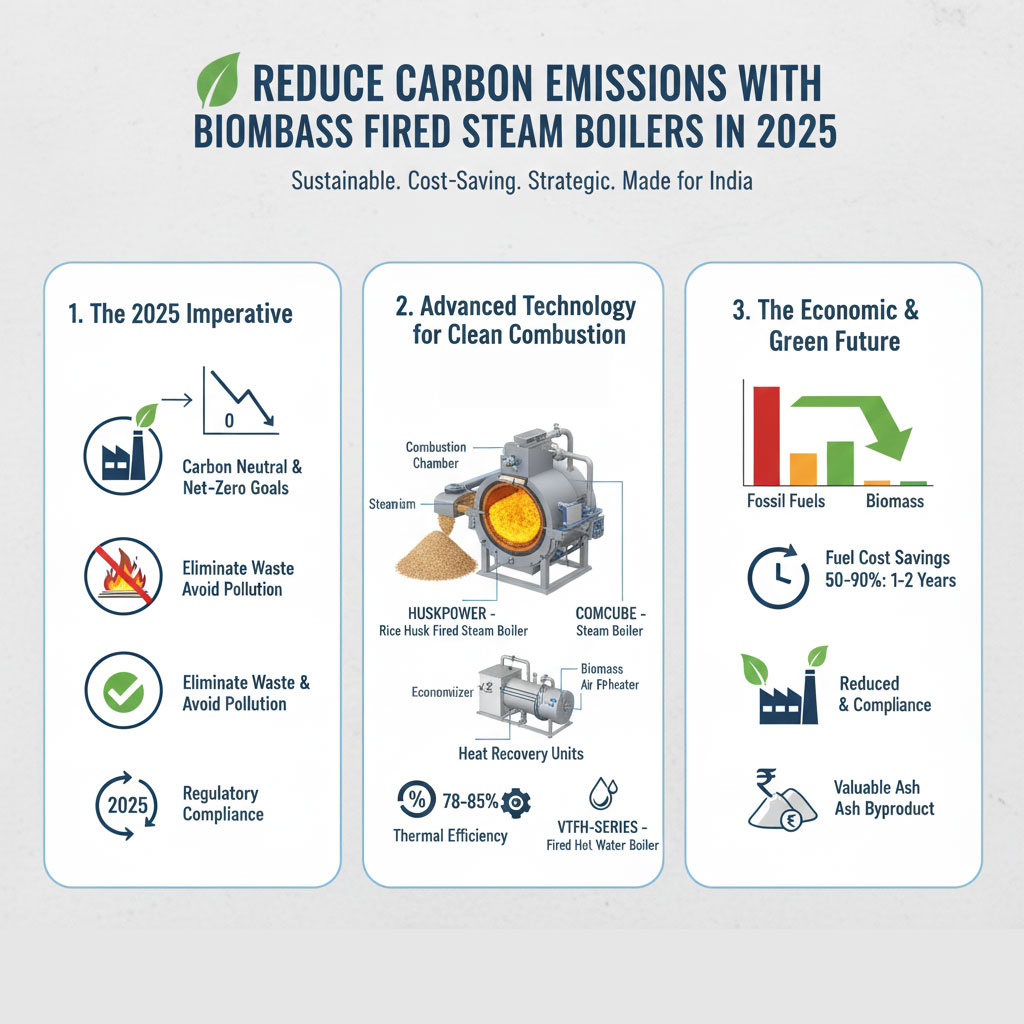

1. The 2025 Imperative: Decarbonization and Compliance

For Indian industry, the shift to biomass is driven by two powerful forces: cost and compliance.

A. The Carbon Neutral Advantage

Unlike coal or diesel, which release long-stored carbon, biomass is a carbon-neutral fuel. The CO2 emitted during combustion is equivalent to what the plant absorbed during its growth cycle. By utilizing agro-waste, factories are not just switching fuels; they are adopting a circular economy model that significantly lowers their overall carbon footprint. This is essential for companies aiming for net-zero targets by 2030 or 2050.

B. Eliminating Waste, Avoiding Pollution

Agro-waste disposal is a major environmental issue in India. By utilizing this waste, a biomass boiler solves a dual problem: it eliminates the need for waste burning/landfilling and simultaneously replaces high-carbon fossil fuels. This transition is the single most effective way a factory can radically cut both direct and indirect emissions in 2025.

2. Advanced Technology for Clean Combustion

Achieving low emissions requires boiler technology tailored to the specific nature of biomass. Our product lines are engineered for maximum thermal efficiency and clean burn characteristics.

A. High-Efficiency Steam Generation (HUSKPOWER & COMCUBE)

For industries requiring reliable steam power, our specialized boilers ensure clean, complete combustion of diverse biomass fuels:

- HUSKPOWER – Rice Husk Fired Steam Boiler: Specifically designed to handle the high silica ash content of rice husk, the HUSKPOWER series utilizes specialized combustion technologies like Fluidized Bed Combustion (FBC). FBC ensures complete burnout at optimal temperatures (800-900), minimizing CO2 and maximizing heat recovery, leading to both high efficiency and low Particulate Matter (PM) emissions.

- COMCUBE – Biomass Steam Boiler: This compact, multi-pass design is highly efficient for general biomass (like bagasse or pellets). Its robust structure and meticulous air control ensure that maximum heat is transferred to water, reducing fuel consumption and thus, emissions per tonne of steam produced.

B. Hot Water & Utility Heating (VTFH-SERIES)

For process heating and hot water applications, our VTFH-SERIES – Biomass Fired Hot Water Boiler provides an immediate and impactful carbon reduction strategy. By switching from diesel or coal heating to biomass hot water generation, factories immediately remove a major source of fossil fuel CO2 from their utility operations.

C. Heat Recovery for Zero Loss

All our biomass systems prioritize heat recovery (Economisers and Air Preheaters). By utilizing waste flue gas heat to preheat water or air, we boost thermal efficiency by an additional 5% to 10%. Higher efficiency directly means less fuel is burned to achieve the same output, which translates directly to lower emissions.

3. The Economic Benefit of Going Green

While the primary driver in 2025 is environmental compliance, the financial benefits of biomass are unparalleled.

A. Significant Fuel Cost Savings

Biomass is the most cost-effective industrial fuel available in India. For rice mills, the fuel cost for a HUSKPOWER boiler can be near-zero. For others, the cost is a fraction of coal or diesel. These savings mean the investment in a biomass boiler is recovered exceptionally fast—often within 1 to 2 years.

B. High Value Ash Byproduct

The ash generated by biomass (especially Rice Husk Ash, RHA) is often a valuable industrial product (silica) for the construction sector, creating a potential revenue stream rather than a disposal cost.

C. Future-Proofing for 2025 and Beyond

Investing in biomass technology now shields your company from future carbon taxes, pollution penalties, and the price volatility of fossil fuels. It is a strategic move that secures operational costs and aligns your business with the long-term sustainable goals of the Indian economy.

Conclusion: Lead the Change in 2025

The transition to a low-carbon economy is no longer optional—it is essential for survival and growth. By choosing a specialized biomass solution from IndianBoilers.com, whether it’s the efficient HUSKPOWER steam boiler, the robust COMCUBE, or the reliable VTFH-SERIES hot water system, your factory gains a powerful tool to secure a profitable, compliant, and environmentally responsible future.

Ready to dramatically reduce your carbon emissions and fuel costs in 2025?

Contact IndianBoilers.com today for an expert consultation on the ideal biomass solution for your factory.