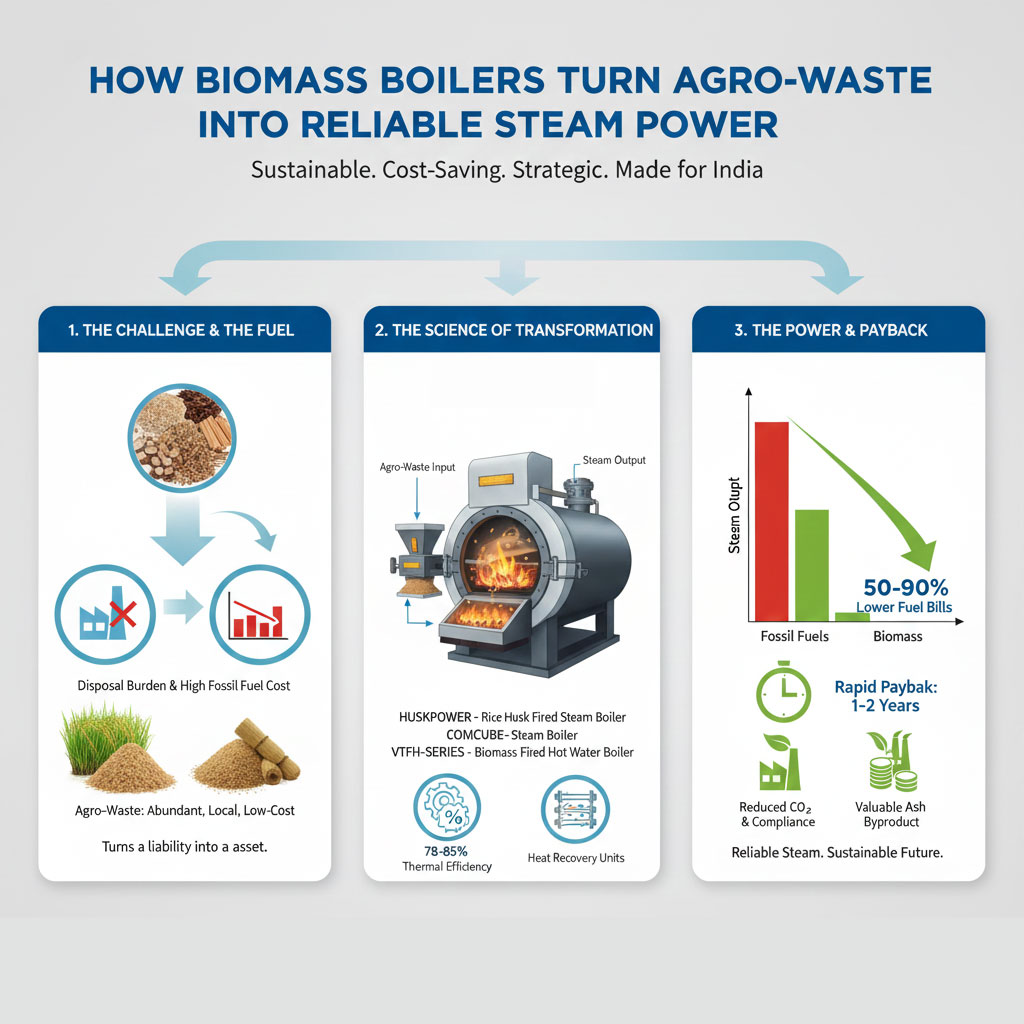

In India’s vibrant agricultural landscape, a valuable resource often goes overlooked: agro-waste. From rice husk and bagasse to groundnut shells and coffee waste, these organic residues are typically seen as disposal challenges. However, for forward-thinking Indian industries, this “waste” is the raw material for a sustainable energy revolution.

At IndianBoilers.com, we specialize in advanced Biomass Fired Boilers that ingeniously transform these agricultural byproducts into reliable, cost-effective, and environmentally friendly steam power. This isn’t magic; it’s smart engineering designed for India’s unique industrial needs, embodied in our product lines like the HUSKPOWER – Rice Husk Fired Steam Boiler and the VTFH-SERIES – Biomass Fired Hot Water Boiler.

1. The Challenge of Agro-Waste: A Dual Problem Solved

Agro-waste presents two significant challenges that biomass boilers directly address:

- Disposal Burden: Improper disposal of agro-waste can lead to environmental pollution (e.g., stubble burning), land degradation, and health hazards. Industries often incur costs for its disposal.

- Energy Deficit: Concurrently, industries face a constant demand for steam, often reliant on expensive and polluting fossil fuels with volatile prices.

Biomass boilers offer a singular solution, simultaneously eliminating waste and generating valuable energy.

2. The Science of Transformation: From Residue to Energy

The process of turning agro-waste into steam power is a testament to specialized boiler engineering. It involves optimizing combustion for diverse organic materials and efficiently transferring that heat to water.

A. Fuel Preparation: Optimizing the “Waste”

While often used in its raw form (e.g., rice husk direct from mills), some agro-waste benefits from minimal preparation:

- Sizing: Chopping larger residues (like wood chips) into smaller, uniform pieces for consistent feeding.

- Drying (if necessary): While many agro-wastes (like rice husk) are low in moisture, very wet biomass might require pre-drying to boost combustion efficiency.

- Densification (Optional): For transport over long distances, waste can be densified into briquettes or pellets, increasing its bulk density and reducing logistics costs.

B. Advanced Combustion: Extracting Maximum Heat

The heart of a biomass boiler is its combustion system, which must handle the unique properties of agro-waste (low calorific value per unit volume, varying moisture, high ash content).

- Fixed Grate / Overfeed Boilers (e.g., VTFH-SERIES): For smaller capacities or specific applications like hot water generation, fuel is fed onto a stationary or moving grate. Primary air is supplied from below the grate, and secondary air above the fuel bed, ensuring complete combustion. This robust design, part of our VTFH-SERIES – Biomass Fired Hot Water Boiler, is common for fuels like bagasse or wood chips.

- Fluidized Bed Combustion (FBC) Boilers (e.g., HUSKPOWER): For larger capacities and a wider range of fuels (especially high-ash fuels like rice husk), FBC is highly effective. The HUSKPOWER – Rice Husk Fired Steam Boiler leverages this for maximum efficiency.

- Principle: Air is blown upwards through a bed of inert material (e.g., sand), causing it to “fluidize” or behave like a boiling liquid.

- Combustion: Agro-waste is injected into this hot, turbulent bed, leading to extremely efficient and complete combustion at relatively lower temperatures (800-900 C). This minimizes harmful NOx formation and allows for excellent control over the burning process.

Key Benefit: Efficient combustion means more heat extracted from less fuel, directly translating into lower operating costs.

C. Heat Transfer: Converting Heat to Steam/Water

Once the agro-waste is combusted, the generated heat must be efficiently transferred to water to produce steam or hot water.

- Three-Pass Design (e.g., COMCUBE): Many of our robust designs, including the compact COMCUBE – Biomass Steam Boiler series, utilize a multi-pass design (typically three passes) for flue gases. This maximizes the surface area of heat exchange between the hot gases and the boiler water, ensuring high thermal efficiency.

- Water Tube or Smoke Tube Design: Depending on the capacity and pressure requirements, the boiler will be either water tube (where water flows inside tubes surrounded by hot gases) or smoke tube (where hot gases flow inside tubes surrounded by water). Both designs are optimized for maximum heat absorption.

- Heat Recovery Units: Essential for maximizing efficiency:

- Economiser: Uses hot flue gases to preheat incoming feedwater.

- Air Preheater (APH): Uses hot flue gases to preheat combustion air.

- Impact: These units can boost overall boiler efficiency by an additional $5\%$ to $10\%$, further reducing fuel consumption.

3. The Power of Reliable Steam: Applications Across Indian Industry

The steam/hot water generated from agro-waste isn’t just “green energy”; it’s consistent, high-quality power essential for diverse industrial processes:

- Rice Mills (Ideal for HUSKPOWER): Critical for parboiling, drying, and conditioning paddy using low-cost steam.

- Textile Units (Ideal for COMCUBE/VTFH-SERIES): Used for dyeing, sizing, printing (steam), and utility heating (hot water).

- Food Processing: Essential for cooking, sterilization, pasteurization (steam/hot water).

- Pulp & Paper: Provides heat for drying and other process-intensive operations.

- Pharmaceuticals: Used for sterilization, heating, and humidification.

A. The End Result: Stable Operation, Lower Costs

By turning agro-waste into reliable steam, biomass boilers deliver:

- Stable Steam Output: Consistent pressure and temperature, crucial for uninterrupted production.

- Significantly Lower Fuel Bills: The primary driver of ROI and long-term savings.

- Reduced Environmental Footprint: Helping industries meet sustainability goals and regulations.

- Sustainable Resource Management: Contributing to a circular economy by valorizing agricultural byproducts.

Conclusion: Biomass Boilers – The Smart, Sustainable Choice

The future of industrial steam in India is undeniably linked to sustainable energy sources. IndianBoilers.com’s HUSKPOWER, COMCUBE, and VTFH-SERIES offer robust, proven solutions that directly address the challenges of waste management and energy costs. They empower factories to tap into a vast, local, and renewable energy supply, transforming agro-waste from a burden into a powerful asset.

Ready to harness the power of agro-waste for your industrial steam needs?

Contact IndianBoilers.com today to discover our range of efficient Biomass Fired Boilers and begin your journey towards a greener, more profitable operation.