In 2026, the industrial landscape has shifted from “production at any cost” to “efficiency by design.” For Indian manufacturers, the transition to biomass energy is no longer just a sustainability goal—it is a survival strategy in an era of volatile fossil fuel prices and tightening carbon regulations.

At IndianBoilers.com, we’ve seen the 2026 efficiency benchmarks reach new heights. This year, the focus is on hyper-automation, thermal intelligence, and aggressive ROI.

Here is the definitive breakdown of the 2026 biomass boiler trends and the savings you can expect to unlock.

1. The 2026 Efficiency Benchmark: What Has Changed?

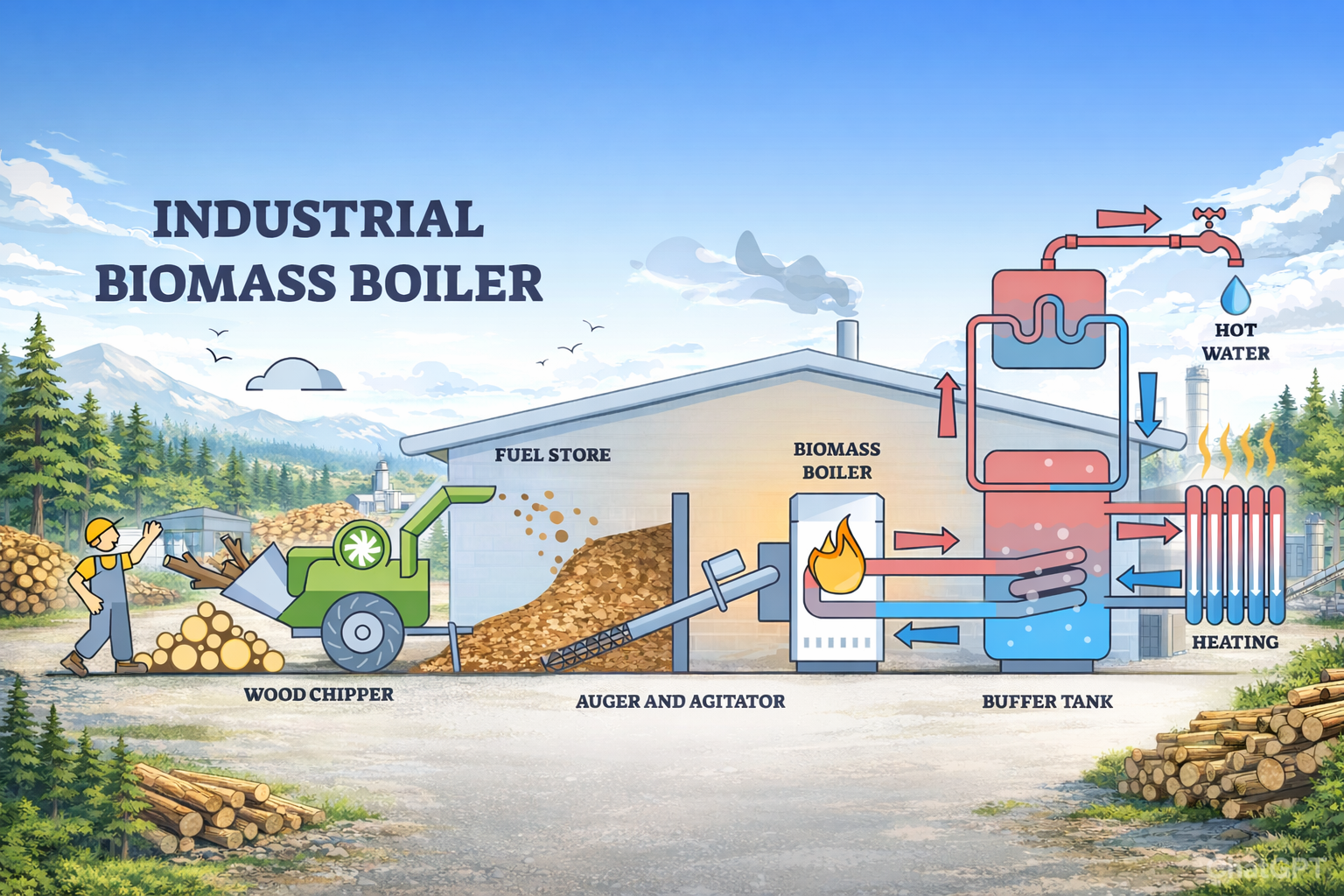

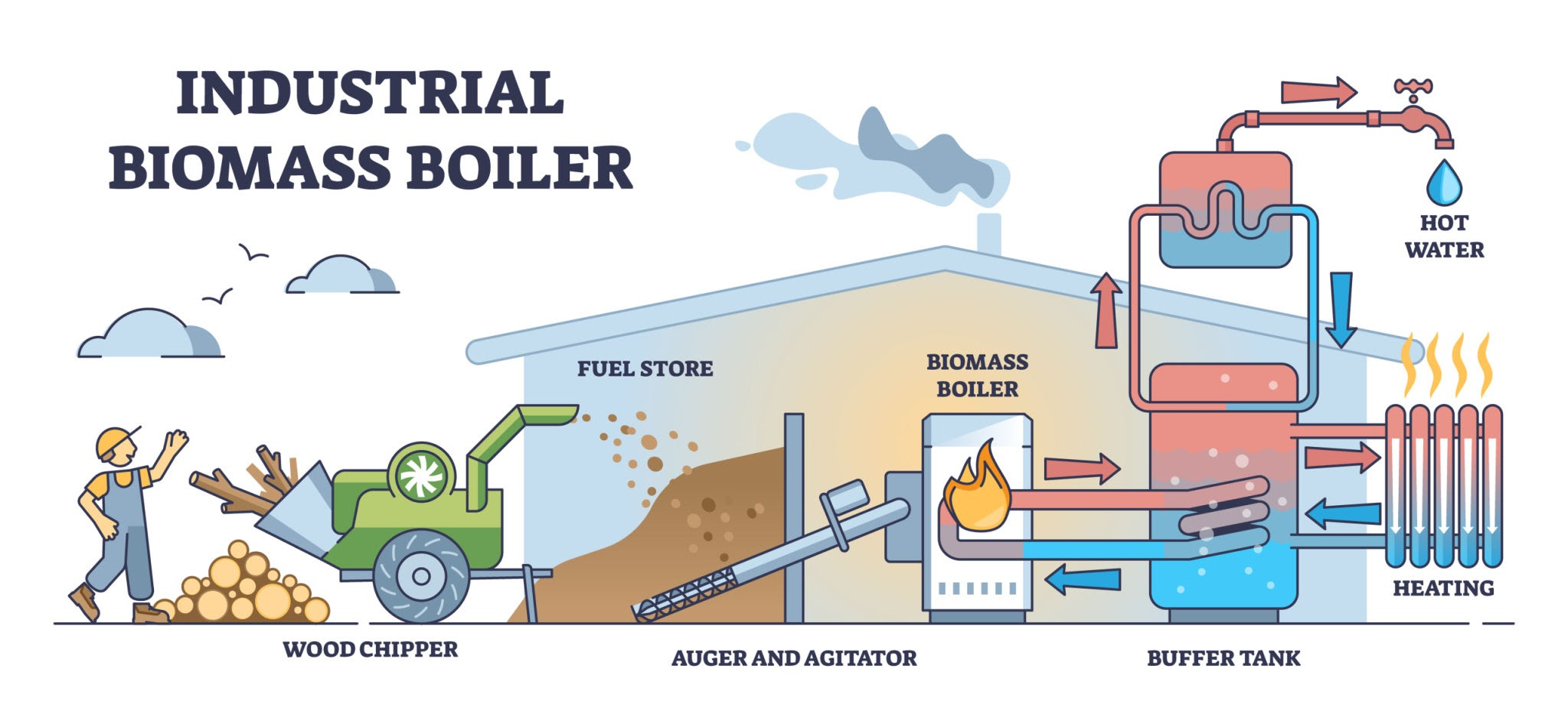

In the past, biomass boilers were often seen as “secondary” or “backup” systems. In 2026, they have become the primary heat source for India’s textile, food processing, and pharmaceutical hubs. The new standard for efficiency is driven by three key technological shifts:

A. The Rise of “Thermal Intelligence” (AI & IoT)

2026 is the year of the Autonomous Boiler. Modern systems are now equipped with O2 and CO sensors that communicate directly with AI-driven control panels. These systems adjust air-to-fuel ratios in real-time, pushing thermal efficiency into the 88% to 92% range. This removes the “human error” factor, ensuring that every gram of fuel is converted into maximum energy.

B. “White Coal” Dominance

Raw wood and agricultural waste are being replaced by high-density biomass pellets and briquettes (often called “White Coal”). With a moisture content now consistently below 6-10%, these fuels offer a calorific value that rivals low-grade coal but with significantly lower ash disposal costs.

C. Heat Recovery 2.0

Modern boilers are no longer standalone units; they are integrated thermal loops. The use of Condensing Heat Exchangers and Air Preheaters (APH) allows factories to capture latent heat that used to escape through the chimney, redirecting it back into the feedwater or process drying.

2. ROI & Savings Revealed: The Math of 2026

Why are manufacturers switching now? The ROI has never been more aggressive. When we compare fuel types in the current 2026 market, the savings are undeniable.

Fuel Price Comparison (2026 Estimates)

| Fuel Type | Approx. Cost | Calorific Value (kcal/kg) | Cost per 1,000 kcal |

| Furnace Oil | ₹75 – ₹85 / Litre | 9,800 | ~₹8.10 |

| Imported Coal | ₹14,000 / Ton | 5,500 | ~₹2.50 |

| Biomass Briquettes | ₹7,000 – ₹9,000 / Ton | 4,000 | ~₹1.80 |

The Saving: Switching from oil to a biomass system typically results in a 70% reduction in fuel costs. Even against coal, biomass remains the winner once you factor in the rising “Coal Cess” and the lower maintenance requirements of modern biomass-specific grates.

3. Top Trends Shaping the Industry in 2026

1. Miniaturization and Decentralization

Space is at a premium in modern industrial parks. The trend for 2026 is “Plug-and-Play” modularity. Systems like the COMCUBE are designed for high-density areas, reducing installation time by 40% while maintaining the steam precision required by boutique pharma labs and food startups.

2. Multi-Fuel Versatility

Energy security is a priority. 2026 models feature Staged Combustion and flexible grate designs (like the STEAMAX series), allowing manufacturers to switch between rice husks, wood pellets, and sawdust based on seasonal availability without recalibrating the entire system.

3. Automated Ash Management

One of the biggest historical “pains” of biomass was ash handling. Modern 2026 systems now feature Automated Ash Removal Systems, which vacuum residues into sealed containers, maintaining a “clean-room” environment suitable for food and hygiene-sensitive industries.

4. Product Spotlight: Matching Technology to Your “Thermal DNA”

Every factory has a unique thermal requirement. At IndianBoilers.com, we’ve engineered our 2026 lineup to address these specific industrial needs:

- COMCUBE – Biomass Fired Boiler: The ideal partner for small-to-midscale industries where space is limited but steam demand is constant.

- STEAMAX – Briquette Fired Boiler: Our flagship for high-output steam generation, optimized for the lowest possible cost-per-ton of steam.

- VTFH-SERIES – Biomass Fired Water Boiler: Perfect for chemical refining and frying processes. By replacing thermic fluid oil with biomass, manufacturers are slashing heating costs by nearly 60%.

- AQUAMAX – Briquette Fired Water Heater: Designed for the dairy and poultry sectors, providing an uninterrupted flow of high-temperature water with zero thermal wastage.

- AIRMAX – Briquette Fired Air Generator: Delivers 100% pure, indirect hot air for drying processes. Essential for maintaining “Export Quality” standards in tea, spices, and chemicals.

5. Navigating Policy and Subsidies in 2026

The Indian government’s National Bioenergy Programme (valid through March 2026) remains a major catalyst.

- Central Financial Assistance (CFA): Project developers can still access significant subsidies for setting up biomass pellet plants and cogeneration projects.

- Carbon Credits: With the expansion of the Indian Carbon Market, companies using biomass are now able to monetize their emission reductions, adding a secondary revenue stream to the fuel savings.

Conclusion: The Future is Fossil-Free

The data is clear: the most profitable factories in 2026 are those that have decoupled their energy needs from fossil fuels. Biomass technology has matured into a reliable, high-efficiency, and financially superior alternative to coal and oil.

Whether it’s the steam precision of the STEAMAX, the space-saving COMCUBE, or the pure drying power of the AIRMAX, IndianBoilers.com provides the engineered solutions to lead your business into a sustainable, high-margin future.