The Green Revolution in Steam: Why Indian Manufacturers are Switching to Biomass

The global manufacturing landscape is undergoing a seismic shift. As we navigate 2026, the conversation has moved past “why” we should go green to “how fast” we can do it. For Indian industries—ranging from textiles and food processing to pharmaceuticals—the boiler room is the heart of this transformation.

At IndianBoilers.com, we’ve watched the market evolve. The era of volatile furnace oil prices and coal-related regulatory headaches is fading. In its place, the Bio-Energy Series has emerged as the gold standard for sustainable, cost-effective steam generation.

This guide explores why switching to biomass isn’t just an environmental statement—it’s the smartest financial move your plant can make this year.

1. The Economic Reality: Coal vs. Biomass vs. Oil

To understand the Return on Investment (ROI), we must first look at the “Fuel Gap.”

| Fuel Type | Availability | Price Stability | Environmental Impact |

| Furnace Oil / LDO | Import Dependent | Highly Volatile | High Carbon Footprint |

| Coal | Regulatory Hurdles | Rising Cess/Taxes | Heavy Ash & Emission Issues |

| Biomass Pellets/Briquettes | Locally Sourced | Stable | Carbon Neutral |

For an Indian manufacturer, fuel usually accounts for 70-80% of the lifecycle cost of a boiler. By switching to the IndianBoilers.com Bio-Energy Series, many plants report a reduction in fuel bills by as much as 30% to 50% compared to liquid fuels.

2. Calculating Your ROI: The Three Pillars

When calculating the ROI of a biomass transition, don’t just look at the invoice for the new unit. Look at the holistic savings.

A. Direct Fuel Savings

Biomass fuels like rice husk, sawdust briquettes, and wood chips are significantly cheaper per kcal than fossil fuels. With the high thermal efficiency of our Bio-Energy Series boilers, you extract more energy per kilogram of fuel, shortening the payback period.

B. Carbon Credits and Incentives

The Indian government has introduced various PAT (Perform, Achieve, Trade) schemes and renewable energy incentives. Transitioning to biomass allows your facility to earn carbon credits, which can be traded or used to offset other operational emissions.

C. Operational Longevity & Maintenance

Older coal boilers often suffer from heavy slagging and erosion. The IndianBoilers.com Bio-Energy Series is engineered with advanced furnace geometries that ensure complete combustion with minimal residue. Less soot means fewer shutdowns for cleaning and lower annual maintenance contracts (AMC).

3. Technical Edge: The Bio-Energy Series Difference

Why choose the Bio-Energy Series over a generic conversion? It’s all in the engineering. Converting a coal boiler to biomass often leads to “derating” (loss of capacity). Our series is purpose-built for biomass:

- Multi-Fuel Flexibility: Whether it’s mustard husk, groundnut shells, or pellets, our systems handle varying moisture contents with ease.

- High Thermal Efficiency: Designed to hit efficiency benchmarks that rival even the best gas-fired units.

- Automated Feeding Systems: Gone are the days of manual shoveling. Our series features smart conveyors that sync with steam demand.

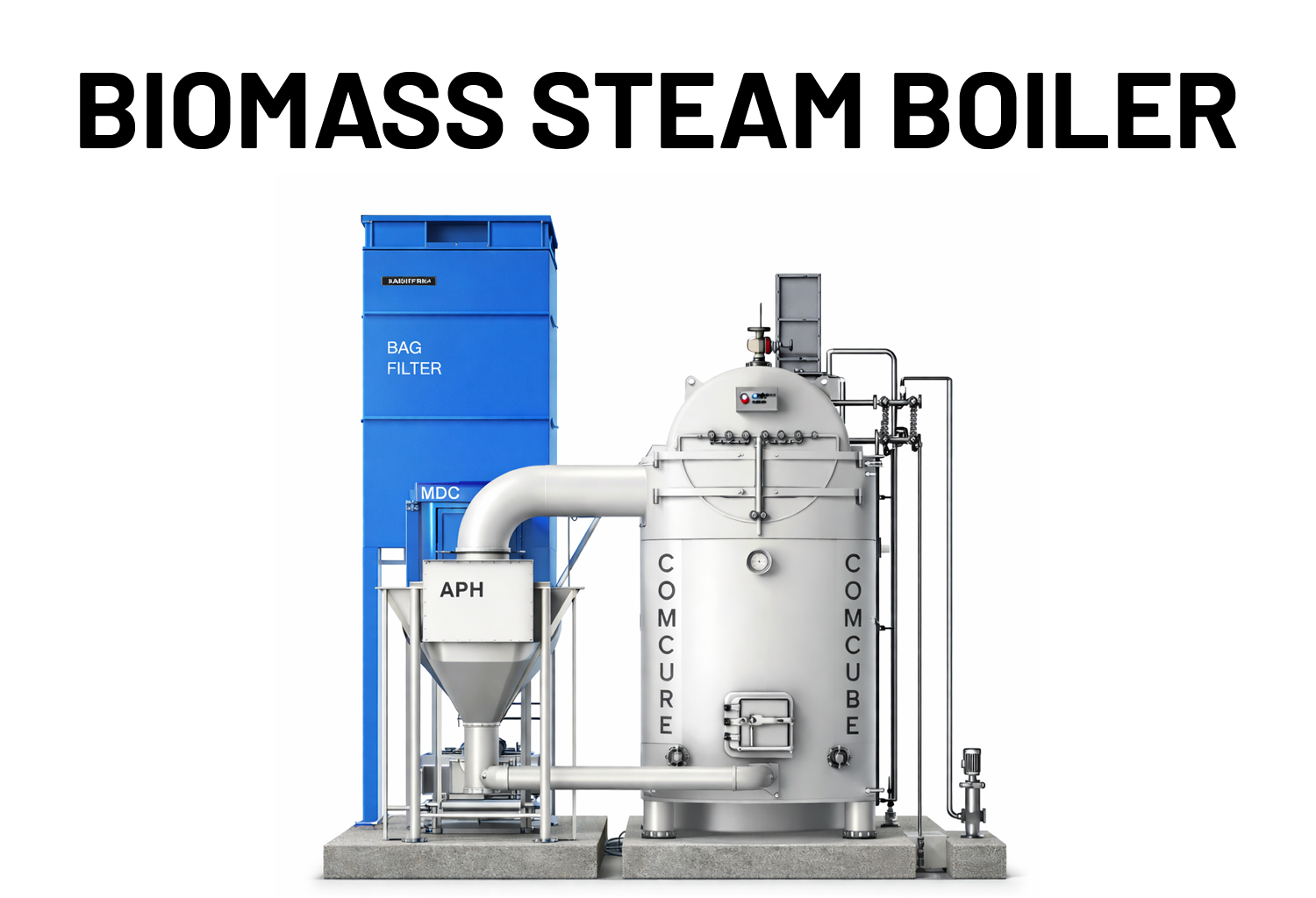

- Advanced Dust Collection: We integrate high-efficiency cyclonic separators and bag filters to ensure your chimney stays clear and compliant with CPCB (Central Pollution Control Board) norms.

4. Overcoming the “Supply Chain” Myth

A common concern for manufacturers is: “Will I have enough biomass during the monsoon?”

The Indian biomass market has matured. There are now organized aggregators providing year-round supply of standardized briquettes and pellets. Furthermore, the Bio-Energy Series by IndianBoilers.com is designed with a “Fuel-Agnostic” furnace, meaning if one type of biomass is scarce, the system can easily adapt to another without significant recalibration.

5. The “Payback” Timeline

In the current Indian industrial climate, a medium-sized manufacturer (running 20 hours a day) typically sees the following ROI timeline after installing a Bio-Energy Series boiler:

- Months 1-6: Immediate drop in monthly OpEx. Training of staff on automated controls.

- Months 12-18: Full recovery of the initial capital expenditure (CAPEX) through fuel savings alone.

- Year 2 onwards: Pure profit. The boiler effectively “pays” for itself, and the savings contribute directly to your company’s bottom line.

“Switching to biomass wasn’t just about compliance for us; it was about survival. With the IndianBoilers.com Bio-Energy Series, we slashed our steam cost by 42% in the first year.”

— Leading Textile Manufacturer, Gujarat.

6. Environmental Leadership as a Brand Asset

In 2026, your buyers care about your supply chain. Whether you are exporting to Europe or selling to eco-conscious Indian consumers, having a “Zero-Carbon Steam” certificate is a massive competitive advantage. It positions your brand as a leader in the green transition, not a laggard.

Conclusion: The Time is Now

The subsidies are available, the technology is proven, and the fuel is local. Continuing to burn expensive, polluting fossil fuels is no longer just an environmental risk—it’s a financial one.

The Bio-Energy Series from IndianBoilers.com offers you a seamless bridge to a cleaner, more profitable future. We don’t just sell you a boiler; we partner with you to engineer a total energy solution that respects both your balance sheet and the planet.