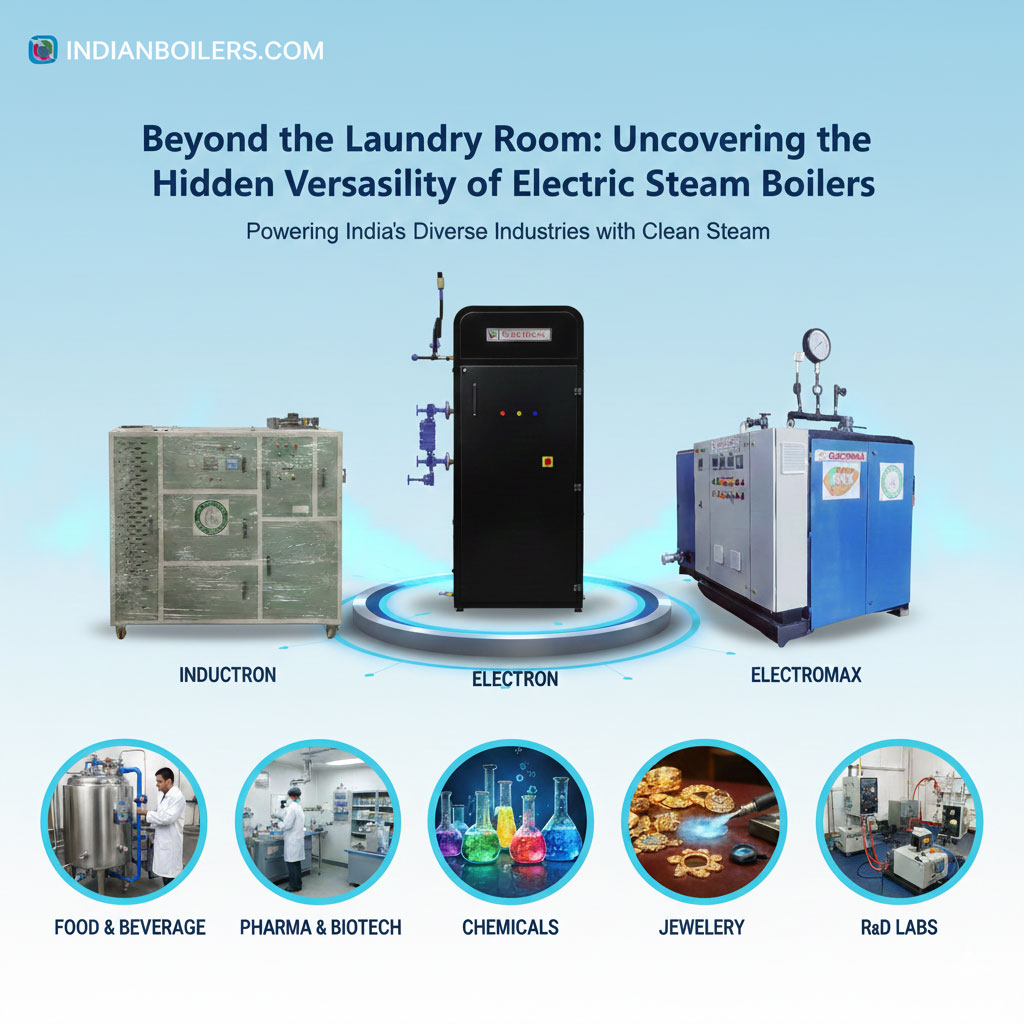

Beyond the Laundry Room: Uncovering the Hidden Versatility of Electric Steam Boilers in India

When you think of steam boilers, images of bustling laundries or essential sterilization in hospitals often come to mind. And it’s true, electric steam boilers like our ELECTRON and ELECTROMAX units are cornerstones in these sectors, providing reliable, clean steam.

But what if we told you that the quiet efficiency and precise control of electric steam boilers are driving innovation and streamlining operations in a surprising array of Indian industries?

The truth is, the applications for electric steam boilers extend far beyond the conventional. Their inherent advantages – zero on-site emissions, instant steam generation, and compact footprint – make them ideal for niche and high-tech processes where traditional fuel-fired boilers simply can’t compete.

Let’s dive into some lesser-known, yet critical, applications where electric steam boilers are making a significant impact across India.

1. Food Processing & Beverage Production: Purity is Paramount

India’s booming food and beverage industry demands the highest standards of hygiene. Steam is essential for:

- Sterilization & Sanitation: Cleaning tanks, pipes, and bottling equipment.

- Cooking & Baking: Direct steam injection for cooking vegetables, pulses, or baking bread.

- Pasteurization: Gentle heating for milk, juices, and other beverages.

- CIP (Clean-in-Place) Systems: Ensuring internal cleaning without disassembly.

Why Electric Boilers Shine Here: Fuel-fired boilers can introduce combustion byproducts that compromise food safety. Electric boilers, like our ELECTRON series, offer ultra-pure, contamination-free steam, crucial for maintaining product integrity and meeting stringent food safety regulations. Their precise temperature control also prevents scorching, preserving the quality and taste of sensitive food products.

2. Pharmaceuticals & Biotech: Precision and Asepsis

The pharmaceutical sector cannot compromise on sterility. Every process, from drug formulation to equipment sterilization, requires absolute precision and an aseptic environment.

- Autoclaves & Sterilizers: For sterilizing lab equipment, glassware, and active pharmaceutical ingredients (APIs).

- Clean Room Humidification: Maintaining precise humidity levels in clean rooms without introducing contaminants.

- Jacketed Vessels: Heating reactants in controlled chemical processes.

Why Electric Boilers Shine Here: The ability of our ELECTROMAX and INDUCTRON models to produce high-quality, dry saturated steam almost instantly, with no flue gases, makes them indispensable. They support validated processes, ensuring consistent performance crucial for drug efficacy and patient safety.

3. Chemical & Specialty Chemicals Manufacturing: Controlled Reactions

From dyes to polymers, India’s chemical industry relies on controlled heat for various reactions.

- Reactor Heating: Maintaining specific temperatures for chemical synthesis.

- Distillation & Evaporation: Separating compounds through steam heating.

- Heat Exchangers: Providing indirect heat for various processes.

Why Electric Boilers Shine Here: In environments dealing with flammable chemicals, the absence of an open flame in electric boilers is a significant safety advantage. Furthermore, the fine-tuned temperature control offered by our units ensures optimal reaction kinetics, crucial for product yield and quality in specialty chemical production.

4. Research & Development Labs: Versatility for Innovation

University labs, corporate R&D centers, and scientific institutions often require small to medium quantities of steam for diverse experimental setups.

- Pilot Plants: Testing new processes on a smaller scale before industrial rollout.

- Material Science: Curing composites, testing steam resistance.

- Environmental Chambers: Creating controlled environments for experiments.

Why Electric Boilers Shine Here: Their compact size and easy installation mean they can fit into tight lab spaces. The rapid startup and shutdown capabilities of models like our ELECTRON make them ideal for intermittent or on-demand use, saving energy when not needed.

5. Precious Metal Refining & Jewellery Manufacturing: Clean & Consistent

In the intricate world of precious metals, steam plays a role in cleaning, pickling, and even some casting processes.

- Degreasing & Cleaning: Removing impurities and oils from gold, silver, and platinum components.

- Lost-Wax Casting: Melting out wax from molds with precision.

Why Electric Boilers Shine Here: The requirement for extremely clean processes to prevent contamination of valuable metals makes electric steam a superior choice. The consistent pressure and temperature ensure predictable results for high-value products.

The Indian Boilers Advantage: Reliability Meets Innovation

At Indianboilers.com, we understand the evolving needs of Indian industry. Our range of electric steam boilers is designed to meet these challenges head-on:

- Electric Steam Boiler – ELECTRON Series: Our workhorse, perfect for general process steam, sterilization, and humidification.

- Induction Steam Boiler – INDUCTRON Series: For applications demanding rapid response and precise control, often in a compact footprint.

- Electric Steam Boiler IBR Appoved – ELECTROMAX Series: High-capacity electric boilers for larger industrial needs, offering unparalleled efficiency.

No matter your industry, if you need clean, reliable, and controllable steam, consider the profound advantages of switching to electric. You might be surprised at how our solutions can revolutionize your operations.

Ready to explore how an electric steam boiler can optimize your unique application? Contact Indianboilers.com today for a free consultation!