Indian industries like textiles, food processing, chemicals, and pharmaceuticals rely heavily on steam boilers for efficient operations. With rising energy costs and sustainability mandates under India’s Make in India initiative, 2025 sees a shift toward high-efficiency, biomass-compatible models from manufacturers like Indian Boilers. These top 10 types balance performance, affordability, and compliance with IBR regulations.

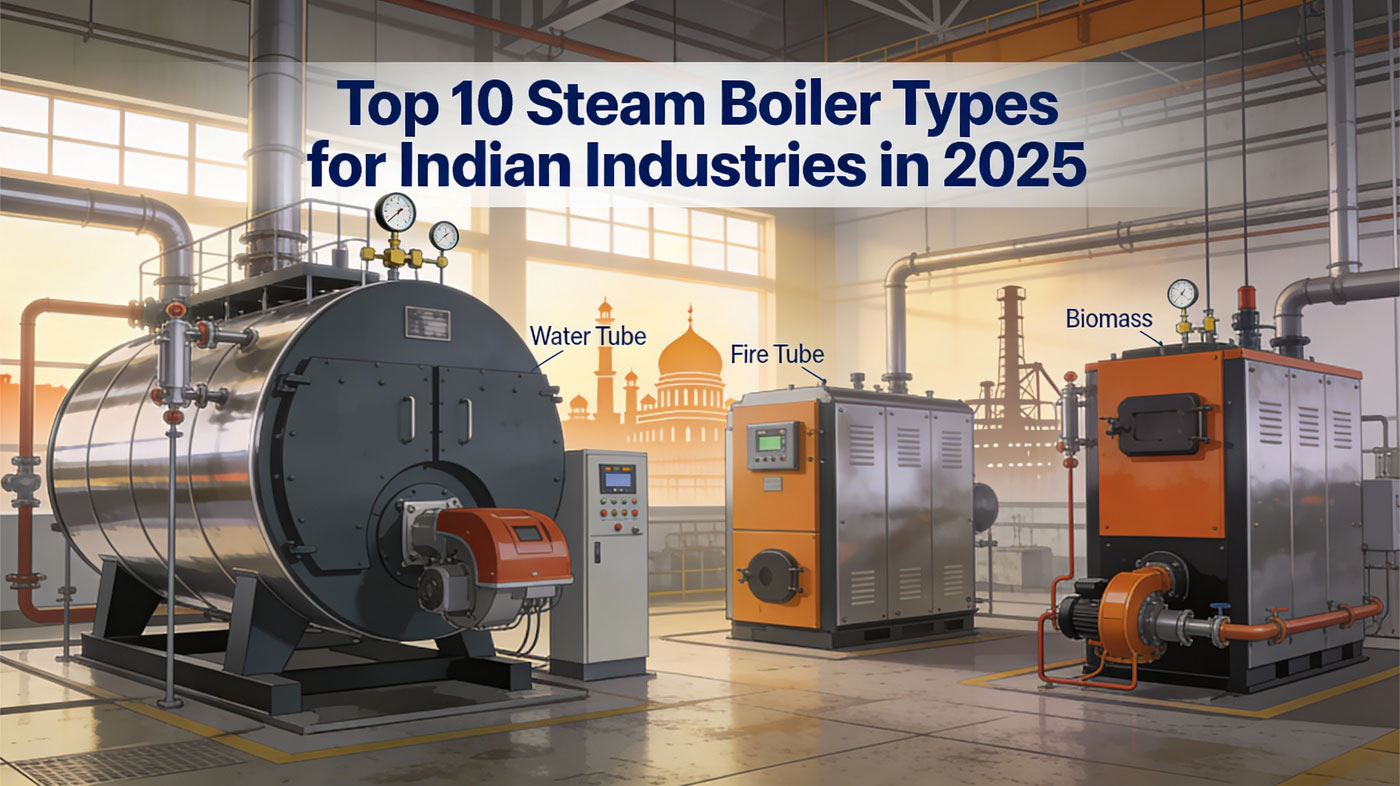

Fire Tube Boilers

Fire tube boilers remain popular in small to medium Indian factories due to their simple design and quick steam generation. Hot gases pass through tubes surrounded by water, ideal for textile dyeing and rice mills with capacities up to 25 TPH. Indian Boilers offers fully automatic versions for reliable low-pressure steam.

Water Tube Boilers

Water tube designs dominate high-pressure applications in power plants and refineries, where water circulates in tubes heated externally. They handle larger capacities (over 50 TPH) and rapid load changes, suiting chemical and pharmaceutical sectors. Enhanced safety features make them compliant for Indian heavy industries.

Biomass-Fired Boilers

Agro-waste like rice husk and bagasse powers these eco-friendly boilers, cutting fuel costs by 40% for MSMEs. Fluidized Bed Combustion (FBC) models from Indian manufacturers excel in food processing and paper mills. 2025 upgrades include multi-fuel grates for sustainability.

Oil & Gas Fired Boilers

Clean-burning oil or LPG-fired boilers provide instant steam for urban factories facing biomass logistics issues. High efficiency (up to 90%) suits pharmaceuticals and distilleries with precise temperature control. Compact designs fit space-constrained Indian plants.

Coal-Fired Boilers

Robust coal boilers serve cement and steel industries with high-capacity output, though 2025 models incorporate pollution controls like electrostatic precipitators. They offer low operational costs in rural areas abundant with coal supply.

Electric Boilers

Zero-emission electric boilers gain traction in emission-sensitive zones like Delhi-NCR for small-scale operations under 1 TPH. Instantaneous steam suits labs and garment units, with low maintenance.

Wood-Fired Boilers

Sustainable wood-fired options thrive in furniture and plywood industries, using local timber waste. Indian Boilers’ models feature automatic feed systems for consistent output in decentralized manufacturing.

Waste Heat Recovery Boilers (WHRB)

These capture exhaust heat from gas turbines or furnaces, boosting overall efficiency by 20-30% in cogeneration plants. Ideal for sugar mills and refineries pursuing net-zero goals.

Condensing Boilers

Recovering latent heat from flue gases, condensing boilers hit 98% efficiency for low-temperature processes like sterilization. Emerging in green textile parks across India.

Hybrid Boilers

Combining biomass and oil/gas, hybrid models offer fuel flexibility amid volatile prices. Perfect for seasonal industries like food processing, ensuring uninterrupted steam supply.

Contact Indian Boilers.com for customized installations tailored to your industry’s needs, with IBR-approved models ready for 2025 deployment.