In an era defined by the urgent need for decarbonization and energy efficiency, the industrial sector is rapidly turning its attention to cleaner heating solutions. While biomass boilers offer a sustainable path for those with access to agro-waste, a different kind of clean energy revolution is quietly underway: Electric Boilers. These advanced systems offer unparalleled cleanliness, precision, and operational simplicity, making them the frontrunners in industries striving for zero on-site emissions.

At IndianBoilers.com, we are at the forefront of this transition, offering a comprehensive range of electric heating solutions. From the compact ELECTRON – Electric Steam Boiler to the robust ELECTROMAX – Electric IBR Steam Boiler, the precise ELECTROPAC – Electric Thermic Fluid Heater, the versatile ELECTRO AQUA – Electric Hot Water Boiler, the innovative ELECTROAIR – Electric Hot Air Generator, and the cutting-edge INDUCTRON – Induction Boiler, we provide a full spectrum of electric power to meet diverse industrial heating needs.

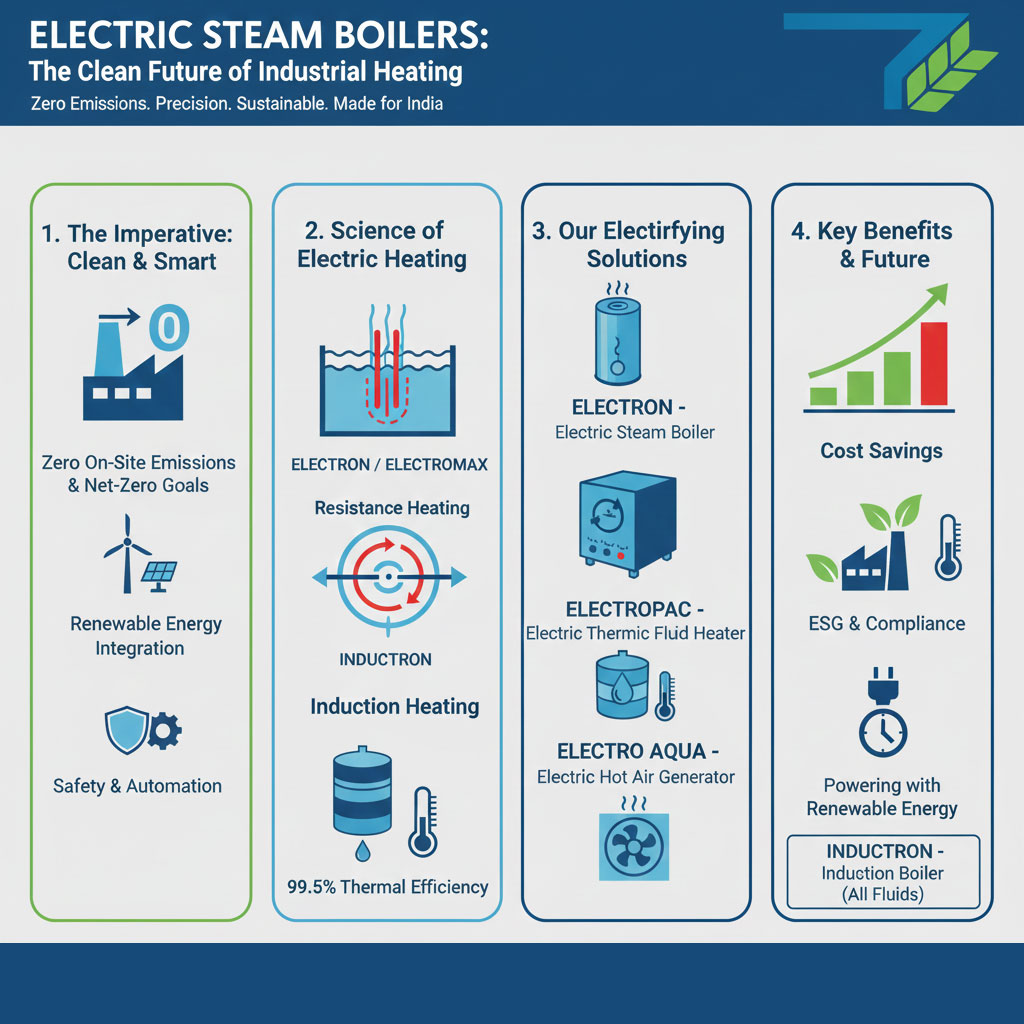

1. The Imperative for Clean Heating: Why Electric Now?

Several converging trends are making electric heating an increasingly attractive and necessary choice for industries.

A. Decarbonization and Net-Zero Goals

- Zero On-Site Emissions: Electric boilers produce zero direct CO2, NOx, or SOx emissions at the point of use. This is a game-changer for industries committed to achieving ambitious net-zero targets and improving air quality around their facilities.

- Renewable Energy Integration: As grid electricity becomes increasingly decarbonized with renewable sources (solar, wind, hydro), electric boilers become even greener, offering a path to genuinely carbon-free heating. This “indirect” greening of energy makes them future-proof.

B. Regulatory Compliance and ESG Pressures

- Stricter Emission Standards: Governments worldwide are implementing tighter regulations on industrial emissions. Electric boilers inherently meet these standards, saving industries from expensive exhaust gas treatment systems required for fossil fuel combustion.

- ESG (Environmental, Social, and Governance) Reporting: Companies face growing pressure from investors, consumers, and stakeholders to demonstrate their environmental stewardship. Adopting electric heating significantly enhances a company’s ESG profile.

C. Operational Advantages Beyond Emissions

- Safety: No combustion means no fuel storage, no fire hazards, no risk of explosion from combustible gases or liquids, and no dangerous flue gases.

- Simplicity and Automation: Electric boilers are incredibly simple to operate and automate, requiring less manual intervention, eliminating fuel handling, and simplifying maintenance.

- Space Saving: Without the need for fuel storage, combustion air systems, or large exhaust stacks, electric boilers often have a smaller footprint.

- Precision Control: Electric heating offers highly accurate temperature and pressure control, crucial for sensitive processes.

2. The Science of Electric Heating: Resistance vs. Induction

IndianBoilers.com leverages two primary methods for electric heating, each with its unique advantages.

A. Resistance Heating (ELECTRON, ELECTROMAX, ELECTROPAC, ELECTRO AQUA, ELECTROAIR)

- Principle: Electric current passes through resistance heating elements, converting electrical energy directly into heat. These elements are immersed in the water (for steam/hot water) or thermal fluid.

- Heat Transfer: The heated elements transfer energy directly to the fluid, raising its temperature and producing steam or hot water.

- Key Advantages:

- Simplicity: Robust and proven technology.

- Versatility: Can be used for steam, hot water, thermic fluid, and even hot air.

- Efficiency: Near 99.5% thermal efficiency, as almost all electrical energy is converted to usable heat.

- Scalability: Available in a wide range of capacities to suit various industrial needs.

B. Induction Heating (INDUCTRON – Induction Boiler)

- Principle: Instead of resistance elements, induction boilers use an electromagnetic field to directly heat a non-ferrous material (often a specially designed metallic core) through induced eddy currents. This core then transfers its heat to the fluid.

- Heat Transfer: The core heats up directly and transfers this heat to the water or thermal fluid flowing around it.

- Key Advantages (Over Resistance):

- No Direct Contact: The heating element (the coil) does not directly contact the water/fluid, eliminating scaling issues on the heating surfaces (though water treatment is still essential for the bulk fluid).

- Longer Lifespan: Heating elements are not subjected to scaling or corrosion, leading to extended operational life and reduced maintenance.

- Faster Response: Can heat up quickly due to direct electromagnetic energy transfer to the core.

- Compactness: Can be very compact for the energy output.

3. IndianBoilers.com’s Comprehensive Electric Product Range

We offer a specialized electric heating solution for virtually every industrial requirement:

A. For Steam Generation:

- ELECTRON – Electric Steam Boiler: Our core electric steam generator, designed for smaller to medium steam demands where purity and quick start-up are crucial. Ideal for laboratories, pharmaceutical units, hospitals, and small processing lines.

- Features: Compact, fully automatic, rapid steam generation, high efficiency.

- Capacity: From 5 kW to 150 kW (and higher).

- ELECTROMAX – Electric IBR Steam Boiler: For larger steam requirements and higher pressures that fall under the Indian Boiler Regulations (IBR). ELECTROMAX combines the benefits of electric heating with the robustness and safety standards required for heavy industrial use.

- Features: IBR certified, suitable for continuous duty, precise pressure control, no emissions.

- Capacity: From 150 kW to 2,000 kW (or more).

- INDUCTRON – Induction Boiler (for Steam): The next generation in electric steam generation, leveraging induction technology for superior efficiency, minimal scaling on heating surfaces, and enhanced longevity.

- Features: Scale-resistant heating core, rapid heat-up, extremely durable, ideal for demanding processes.

- Capacity: Customizable.

B. For Thermal Fluid Heating:

- ELECTROPAC – Electric Thermic Fluid Heater: Provides precise, high-temperature heat without the need for high pressures (unlike steam). Ideal for paint, chemical, food processing, and textile industries where exact temperature control is critical.

- Features: Safe, flameless operation, uniform heating, robust construction, high efficiency.

- Temperature Range: Up to 300 C or higher.

- Capacity: From 10 kW to 1,000 kW (and higher).

- INDUCTRON – Induction Boiler (for Thermic Fluid): Brings the benefits of induction heating to thermic fluid systems, offering even greater longevity and reduced maintenance for the heating surfaces.

- Features: No resistance elements to scale or burn out, longer fluid life, consistent performance.

- Capacity: Customizable.

C. For Hot Water Generation:

- ELECTRO AQUA – Electric Hot Water Boiler: Efficiently provides hot water for domestic, commercial, and industrial applications. Perfect for hotels, hospitals, laundries, and process heating where clean, instant hot water is needed.

- Features: Compact, easy to install, instant hot water, precise temperature control.

- Temperature Range: Up to 90 C.

- Capacity: From 5 kW to 500 kW.

D. For Hot Air Generation:

- ELECTROAIR – Electric Hot Air Generator: Delivers clean, precise hot air for drying, curing, space heating, and other industrial processes where direct flame contact or combustion gases are undesirable.

- Features: Flameless, precise temperature control, clean air output, quiet operation.

- Temperature Range: Customizable.

- Capacity: From 10 kW to 500 kW.

4. Key Considerations for Adopting Electric Boilers

While the advantages are clear, a successful transition requires careful planning.

A. Electrical Infrastructure

- Power Availability: Ensure your plant has sufficient electrical supply and infrastructure (transformers, switchgear) to handle the boiler’s power demand. Large electric boilers may require significant power upgrades.

- Cost of Electricity: Analyze your electricity tariffs. While electricity is generally more expensive per unit of energy than fossil fuels, the 99.5% efficiency, zero fuel handling, zero emissions, and lower maintenance costs can offset this.

B. Water Treatment

- Essential for Resistance Boilers: Proper water treatment remains crucial for resistance-based electric steam and hot water boilers to prevent scaling on heating elements, which can reduce efficiency and element lifespan.

- Still Important for Induction: While INDUCTRON boilers are less prone to scaling on the heating surface, good water treatment is still necessary to protect the overall system and piping.

C. Renewable Energy Sourcing

- True Decarbonization: To achieve true decarbonization, source your electricity from renewable providers or install on-site renewable generation (e.g., solar panels). This magnifies the environmental benefits of electric boilers.

Conclusion: Embrace the Electric Future with IndianBoilers.com

Electric boilers are no longer just an alternative; they are becoming the preferred solution for forward-thinking industries committed to a cleaner, more efficient, and sustainable future. Their ability to deliver zero on-site emissions, coupled with precision control, safety, and operational simplicity, makes them an indispensable asset in the drive towards net-zero.

At IndianBoilers.com, we are proud to offer a complete suite of electric heating solutions. Whether you need the quick steam of ELECTRON, the IBR-compliant power of ELECTROMAX, the precise heat of ELECTROPAC, the instant hot water of ELECTRO AQUA, the clean air of ELECTROAIR, or the advanced efficiency of INDUCTRON, we have the expertise to electrify your heating processes.

Ready to step into the clean future of industrial heating?

Contact IndianBoilers.com today for a comprehensive consultation on how our electric boiler range can transform your operations and contribute to your sustainability goals.