Electric Boilers for Food, Pharma & Dairy: Safe, Clean Steam Solutions in Critical Industries

The Food, Pharmaceutical, and Dairy sectors operate under the most stringent standards for hygiene, purity, and regulatory compliance. In these critical environments, process heating—especially steam generation—must meet uncompromising criteria. Traditional fossil fuel boilers, with their complex fuel storage, combustion byproducts, and associated flue gases, often pose contamination risks and add significant complexity to compliance protocols.

The solution for these sensitive industries is the Electric Boiler System.

Electric heating delivers the cleanest, safest, and most precise thermal energy available, naturally aligning with the rigorous demands of GMP (Good Manufacturing Practice), HACCP (Hazard Analysis Critical Control Point), and FSSAI guidelines.

At IndianBoilers.com, we specialize in providing these essential, high-purity solutions. Our range, featuring the compact ELECTRON – Electric Steam Boiler, the heavy-duty ELECTROMAX – Electric IBR Steam Boiler, the advanced INDUCTRON – Induction Boiler, the high-temperature ELECTROPAC – Electric Thermic Fluid Heater, and the precise ELECTRO AQUA – Electric Hot Water Boiler, offers a zero-emission path to thermal reliability in the most demanding clean environments.

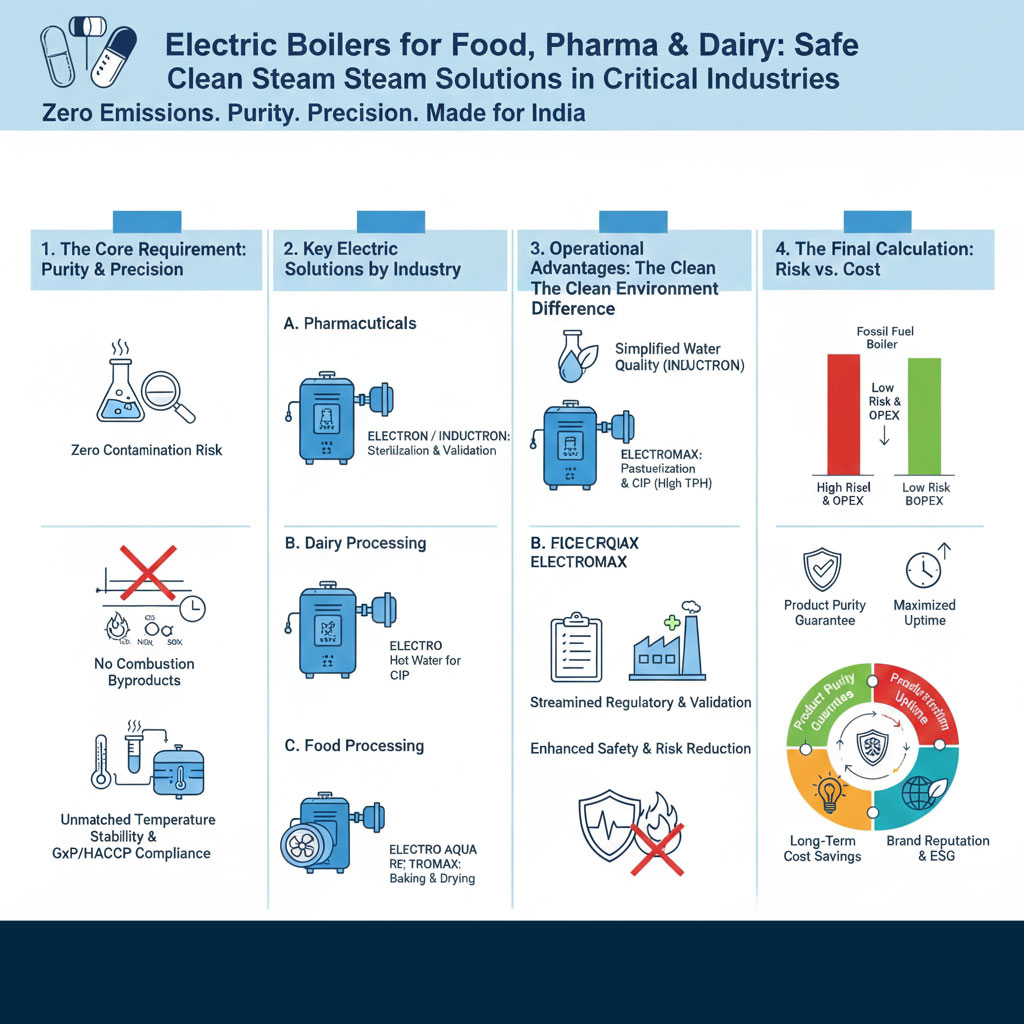

1. The Core Requirement: Purity and Precision

The primary driver for electric boiler adoption in Food, Pharma, and Dairy is the fundamental need for process purity and exacting temperature control.

A. Zero Risk of Combustion Contamination

In traditional combustion boilers, even if the steam itself is pure, the environment and immediate vicinity are affected by pollutants:

- Fume and Odor: Stored fuel oil or diesel can leak and emit odors. Exhaust gases (flue gas) must be vented high above the plant.

- Particulate Matter: Combustion often generates soot and particulate matter which, even with filters, presents a contamination risk if ventilation is poor or if stacks are too close to air intakes.

Electric boilers, by contrast, are zero-emission at the point of use. This eliminates the entire category of combustion-related contamination risk, making them the safest choice for installation adjacent to or within the clean processing areas.

B. Unmatched Temperature Stability

Processes like sterilization (autoclaves in Pharma), pasteurization (Dairy), and retort cooking (Food) require precise temperature and pressure profiles to guarantee product safety and quality.

- Electric Precision: Electric boilers provide instantaneous, highly stable steam/heat, achieving a level of control that is difficult to maintain with cycling fossil fuel burners. This rapid response and minimal pressure fluctuation are crucial for regulatory validation.

- The ELECTRON Advantage: The ELECTRON – Electric Steam Boiler is perfectly suited for autoclave sterilization, offering rapid ramp-up and precise temperature hold, which is critical for meeting validation protocols and minimizing batch cycle times.

2. Key Electric Solutions by Industry Application

The specific demands of each critical industry dictate the choice of electric heating technology.

A. Pharmaceuticals: Sterilization and Validation (ELECTRON & INDUCTRON)

The pharmaceutical industry requires steam primarily for sterilization, moist heat curing, and clean room humidification. The needs are characterized by intermittent, high-peak demand and absolute steam purity.

| Application | Heating Requirement | Product Solution | Why Electric Excels |

| Autoclave Sterilization | High-pressure, saturated steam; rapid steam availability. | ELECTRON – Electric Steam Boiler or INDUCTRON – Induction Boiler | Instant steam generation and precision control vital for GxP validation protocols (e.g., 121 ℃ for 15 mins). Zero emissions allow for installation close to the clean room. |

| Distillation/Reactors | High-temperature, indirect heating; often requires thermal fluid. | ELECTROPAC – Electric Thermic Fluid Heater | Flameless heating and precise temperature control are essential for sensitive chemical reactions and to prevent localized overheating. |

| Clean Room HVAC | Low-pressure, clean steam for humidification. | ELECTRON (Low kW) | Delivers clean steam that doesn’t introduce combustion particles into the highly filtered air circulation system, preserving air quality standards. |

B. Dairy Processing: Pasteurization and CIP (ELECTROMAX & ELECTRO AQUA)

Dairy plants require huge volumes of stable heat for continuous pasteurization and massive amounts of hot water/steam for Clean-in-Place (CIP) procedures.

| Application | Heating Requirement | Product Solution | Why Electric Excels |

| HTST Pasteurization | Continuous, large-volume steam supply; high pressure stability. | ELECTROMAX – Electric IBR Steam Boiler | The ELECTROMAX provides the required large TPH capacity and pressure stability crucial for continuous flow systems, ensuring every drop of milk is heated correctly for microbial safety. |

| Clean-in-Place (CIP) | High-volume hot water (approx 85℃) and low-pressure steam. | ELECTRO AQUA – Electric Hot Water Boiler | Provides instant, non-polluting hot water and is often paired with an ELECTRON for low-pressure steam, streamlining the sanitation loop. |

| Deodorization/Drying | High-temperature heat transfer (steam or thermal fluid). | ELECTROPAC (Indirect heat) or ELECTROMAX | Ensures consistent heat input for drying milk powder or stabilizing fat content without any risk of exhaust fumes contaminating the product. |

C. Food Processing: Retorts and Baking (INDUCTRON & ELECTROMAX)

The food industry utilizes heat for everything from baking and curing to vacuum packaging and sterilization (retorts).

| Application | Heating Requirement | Product Solution | Why Electric Excels |

| Retort Sterilization | High-pressure, high-volume steam for batch cooking. | ELECTROMAX or INDUCTRON | High TPH capacity and precise control over the sterilization curve are necessary to meet FSSAI safety standards for preserved foods. Induction is favored for long-term reliability. |

| Baking/Ovens | Clean, high-temperature hot air or direct thermal fluid heat. | ELECTROAIR – Electric Hot Air Generator | Delivers clean air directly to the oven without the risk of flame or combustion byproducts affecting the flavor or quality of the food product. |

| General Utilities | Steam for jacketed kettles, melting, and forming. | ELECTRON (Decentralized) | Allows small boilers to be placed near each processing station, maximizing steam quality and minimizing energy loss. |

3. Operational Advantages: The Clean Environment Difference

Beyond contamination prevention, electric boilers offer significant operational benefits critical to compliance and efficiency.

A. Water Quality Management

While all boilers require good water treatment, electric boilers make water-side management more predictable:

- Resistance Elements (ELECTRON, ELECTROMAX): Require vigilant treatment to prevent scaling on the elements, which can reduce efficiency.

- Induction Core (INDUCTRON): The non-contact heating core is significantly less susceptible to scaling, making maintenance simpler and ensuring that the high 99.5% efficiency is sustained for longer periods—a crucial factor for validated, continuous operations.

B. Simplified Validation and Compliance

- Auditing Ease: In a highly audited environment (like Pharma and Dairy), the absence of a complex fuel train, burner systems, and emission controls simplifies the compliance paperwork and physical inspection process.

- Pressure Stability: The precision of electric heating makes it easier to consistently meet the Fo (sterilization validation) values in retorts and the holding times/temperatures in pasteurizers—a core regulatory requirement.

C. Enhanced Safety

The elimination of combustible fuel storage, especially in crowded urban industrial zones, significantly de-risks the facility. For critical industries where continuity of supply is vital, this safety factor alone is often sufficient justification for choosing an electric boiler.

4. The Final Calculation: Weighing Cost vs. Risk

For Food, Pharma, and Dairy, the purchasing decision is rarely based on the lowest capital cost; it is based on the lowest risk and the highest guarantee of compliance.

| Factor | Fossil Fuel Boiler | Electric Boiler | Impact on Critical Industries |

| Contamination Risk | Medium to High (Fuel storage, flue gas). | Zero (Flameless, zero emissions). | Crucial: Direct impact on product safety and recall risk. |

| Process Control | Good, but susceptible to burner cycle lag. | Excellent (pm 1 ℃ stability, rapid response). | Critical: Ensures GxP and HACCP temperature holding times are met consistently. |

| Maintenance | High (burner tuning, soot blowing, fuel treatment). | Low (element/core inspection, water treatment). | Operational: Minimizes downtime for validated equipment. |

| Footprint | Large (boiler + fuel storage + stack). | Compact (no stack, no storage). | Logistical: Allows installation in constrained plant utility rooms. |

The slightly higher operating cost of electricity (vs. raw fossil fuel) is overwhelmingly offset by:

- Elimination of high-risk operational failure.

- Reduction of maintenance downtime.

- Guarantee of product purity and regulatory compliance.

This shift in focus—from cheap heat to guaranteed pure heat—makes the electric boiler the financially and strategically sound choice for the Food, Pharma, and Dairy sectors.

Conclusion: Clean Energy for Clean Processes

The Food, Pharmaceutical, and Dairy industries demand the highest standards of safety, control, and cleanliness. By delivering zero on-site emissions, near-perfect 99.5% thermal efficiency, and precision temperature stability, electric heating systems from IndianBoilers.com are the ideal partners for these critical applications.

Whether you need the IBR-certified muscle of the ELECTROMAX for continuous pasteurization, the advanced, scale-resistant purity of the INDUCTRON for pharmaceutical processing, or the specialized high heat of the ELECTROPAC, embracing electrification is the definitive step toward guaranteed product integrity and streamlined compliance.

Ready to eliminate contamination risk and upgrade your process control?

Contact IndianBoilers.com today for an application-specific consultation on implementing the safest and cleanest heating solutions in your food, pharma, or dairy facility.