Electric Boiler Technology: From Immersion Elements to Electrode Types – A Deep Dive

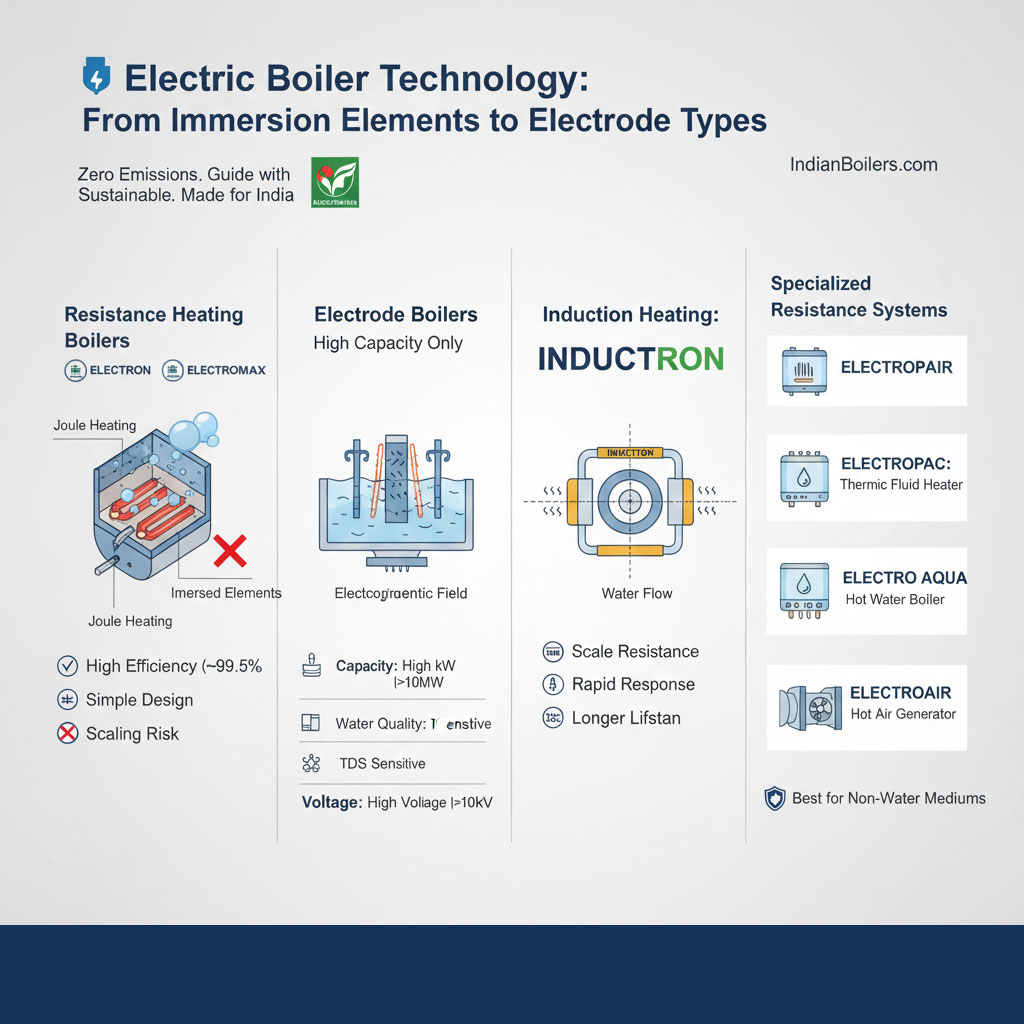

The simplicity and cleanliness of industrial electric boilers have positioned them as the cornerstone of the decarbonized economy. However, not all electric boilers are created equal. The core technology used to heat the water—be it resistance elements, electrode contact, or induction fields—profoundly affects a boiler’s efficiency, maintenance profile, and suitability for specific applications.

Understanding these technical distinctions is vital for any industrial manager looking to make an informed investment.

At IndianBoilers.com, we offer specialized electric heating systems tailored to these technologies: the resistance-based ELECTRON – Electric Steam Boiler and ELECTROMAX – Electric IBR Steam Boiler, the advanced INDUCTRON – Induction Boiler, and specialized resistance systems like ELECTROPAC – Electric Thermic Fluid Heater and ELECTRO AQUA – Electric Hot Water Boiler.

This guide provides a comprehensive technical breakdown of the primary electric boiler technologies, helping you choose the best system for your plant.

1. Resistance Heating Boilers: The Workhorse of Electrification

Resistance heating is the oldest, most reliable, and most common form of industrial electric heating. It is the core technology behind our ELECTRON and ELECTROMAX steam boilers.

A. Principle of Operation

- Joule Heating: Electric current is passed through highly resistant conductors (typically Nichrome or Incoloy). The resistance converts electrical energy directly into thermal energy (heat).

- Heat Transfer: These resistance elements are immersed directly into the boiler water. Heat is transferred from the element surface to the water via conduction and convection.

B. Technical Advantages

- High Efficiency: Resistance boilers boast thermal efficiency approaching 99.5%. Since heat is generated internally, virtually no energy is lost.

- Simple Design: The technology is robust, proven, and relatively simple to manufacture and maintain.

- Water Quality Tolerance: While good water quality is essential, resistance boilers can operate reliably with properly treated city or softened water.

- Flexible Sizing: Capacity is easily scaled by adding or removing heating elements, making it simple to create the low-power ELECTRON or the high-power, IBR-compliant ELECTROMAX.

- Precision Modulation: Capacity can be precisely controlled by staging the heating elements (switching them on/off in banks) to match fluctuating steam demand.

C. Maintenance and Limitations

- Scaling Risk: The primary drawback is that the element surface is the hottest point in the system. If water treatment is inadequate, dissolved solids in the water will precipitate onto the element, forming scale. Scale acts as an insulator, drastically reducing efficiency and leading to premature element failure (burnout).

- Replacement: Elements must be periodically cleaned or replaced, requiring boiler downtime.

2. Electrode Boilers: High Power for Large, Unregulated Steam

Electrode boilers are distinct from resistance types and are typically used in very large, high-pressure industrial applications, often above 10,000 kW capacity.

A. Principle of Operation

- Electrical Conductivity: Electrode boilers rely on the electrical conductivity of the water itself.

- Direct Contact: High-voltage alternating current (AC) is passed directly through the boiler water between submerged electrodes.

- Resistance Heating: The water acts as the resistance element. The energy converted to heat is proportional to the resistance of the water.

B. Technical Advantages and Limitations

| Factor | Description | Impact |

| Capacity | Easily reach extremely high kW output. | Ideal for very large utility power plants or massive industrial users. |

| Efficiency | Also near 99% efficient. | Excellent energy conversion. |

| Water Quality | Highly dependent on water conductivity. | Requires precise control of dissolved solids (TDS) to regulate power output. TDS must be maintained at an exact level, making operation sensitive. |

| Voltage | Typically operate at high voltage (>10 kV). | Requires specialized electrical infrastructure and high-voltage safety measures. |

| Regulation | Not commonly used in India for IBR-compliant industrial steam generation due to complexity and regulation sensitivity. | Limited suitability for common industrial applications where the ELECTROMAX (resistance) is preferred. |

3. Induction Heating: The Future of Clean, Low-Maintenance Heat (INDUCTRON)

Induction heating is the most advanced technology in the electric boiler space, aiming to resolve the scaling and maintenance issues inherent in resistance elements. This is the technology utilized in our INDUCTRON – Induction Boiler.

A. Principle of Operation

- Electromagnetic Field: An electrical current is passed through an induction coil (like a transformer’s primary winding) located outside the pressure vessel or separated from the water.

- Eddy Currents: This coil generates a powerful, rapidly changing electromagnetic field. This field induces circulating eddy currents directly within a special metallic core (the heat exchanger).

- Direct Core Heating: The electrical resistance within the metallic core rapidly heats the core itself.

- Heat Transfer: Water flows over or through the hot core, picking up the heat via conduction.

B. Technical Advantages

- Scale Resistance: The most significant benefit. Since the heating coil is separate from the fluid, and the core heats up uniformly, the core surfaces are less prone to the localized overheating that causes scaling on resistance elements. This drastically reduces maintenance and sustains high efficiency over the boiler’s lifespan.

- Rapid Response: Induction allows for extremely fast heat-up times and precise modulation.

- Longevity: The separation of the electrical component (the coil) from the corrosive/scaling environment (the water) ensures a longer lifespan for the heating mechanism.

C. Applications and Limitations

- Ideal for Sensitive Fluids: INDUCTRON is excellent not just for steam, but also for clean water heating and thermal fluids where element degradation is a concern.

- Cost: The advanced coil and core materials make induction systems generally have a higher initial CAPEX than basic resistance models.

4. Specialized Resistance Systems for Non-Steam Applications

The resistance heating principle is versatile and is adapted across our product line for heat transfer mediums other than steam.

A. ELECTROPAC – Electric Thermic Fluid Heater

- Purpose: To provide high-temperature heat (up to 350 ℃) to a process using a synthetic oil (thermic fluid) instead of water/steam.

- Technical Detail: Uses resistance elements immersed in the thermal fluid inside a high-quality vessel. Because thermal fluid is non-corrosive and non-conductive, the scaling issue is eliminated, making resistance elements an ideal and highly efficient choice for this application.

- Application: Ideal for textile curing, paint baking, chemical reactors, and asphalt heating.

B. ELECTRO AQUA – Electric Hot Water Boiler

- Purpose: To generate pressurized hot water for domestic, HVAC, or low-temperature process heating.

- Technical Detail: Uses low-density resistance elements immersed in water. Simple, reliable, and compact.

- Application: Hospitals, hotels, laundries, and industrial washing stations.

C. ELECTROAIR – Electric Hot Air Generator

- Purpose: To deliver high-temperature, clean air for drying and curing processes.

- Technical Detail: Uses specialized finned resistance elements placed in a duct. Air is forced over the elements, heating it directly.

- Application: Food drying, pharmaceutical coating, and material curing where combustion fumes cannot be tolerated.

5. Summary: Choosing the Right Technology

The decision hinges on the balance between capacity, maintenance tolerance, and budget.

| System Type | IndianBoilers.com Product | Best for… | Key Differentiating Factor |

| Resistance | ELECTRON, ELECTROMAX | Most common industrial steam/hot water, robust, reliable, and cost-effective CAPEX. | Requires vigilant water treatment to prevent scaling on elements. |

| Induction | INDUCTRON | Critical processes demanding high reliability and purity; long-term, low-maintenance operation. | Scale-resistant core; highest long-term efficiency maintenance. |

| Electrode | (High Capacity Only) | Utility-scale power generation or specialized, very high MW steam users. | Highly sensitive to water conductivity (TDS) for power control. |

| Specialized Resistance | ELECTROPAC, ELECTRO AIR | Non-steam heat transfer (thermal fluid or air); where resistance is the optimal method. | Eliminates water-related maintenance issues by using non-water mediums. |

Conclusion: Expertise is Key to Electrification

Transitioning to electric boiler technology is a strategic investment in efficiency and sustainability. However, selecting the wrong technology for your facility’s size or water quality can negate the benefits.

For most industrial steam users requiring IBR compliance and significant capacity, the ELECTROMAX (resistance) offers the best balance of CAPEX and proven performance. For facilities prioritizing minimal downtime and long-term element life, the INDUCTRON (induction) is the superior long-term choice.

Don’t risk efficiency degradation or premature element failure by guessing your technology.

Contact IndianBoilers.com today. Our engineers will analyze your specific water chemistry, steam load, and budget to recommend the perfect electric solution—be it ELECTRON, ELECTROMAX, INDUCTRON, or one of our specialized resistance systems.