Electric vs. Fuel-Fired: Unpacking the True Efficiency and Running Costs of Steam Boilers in India

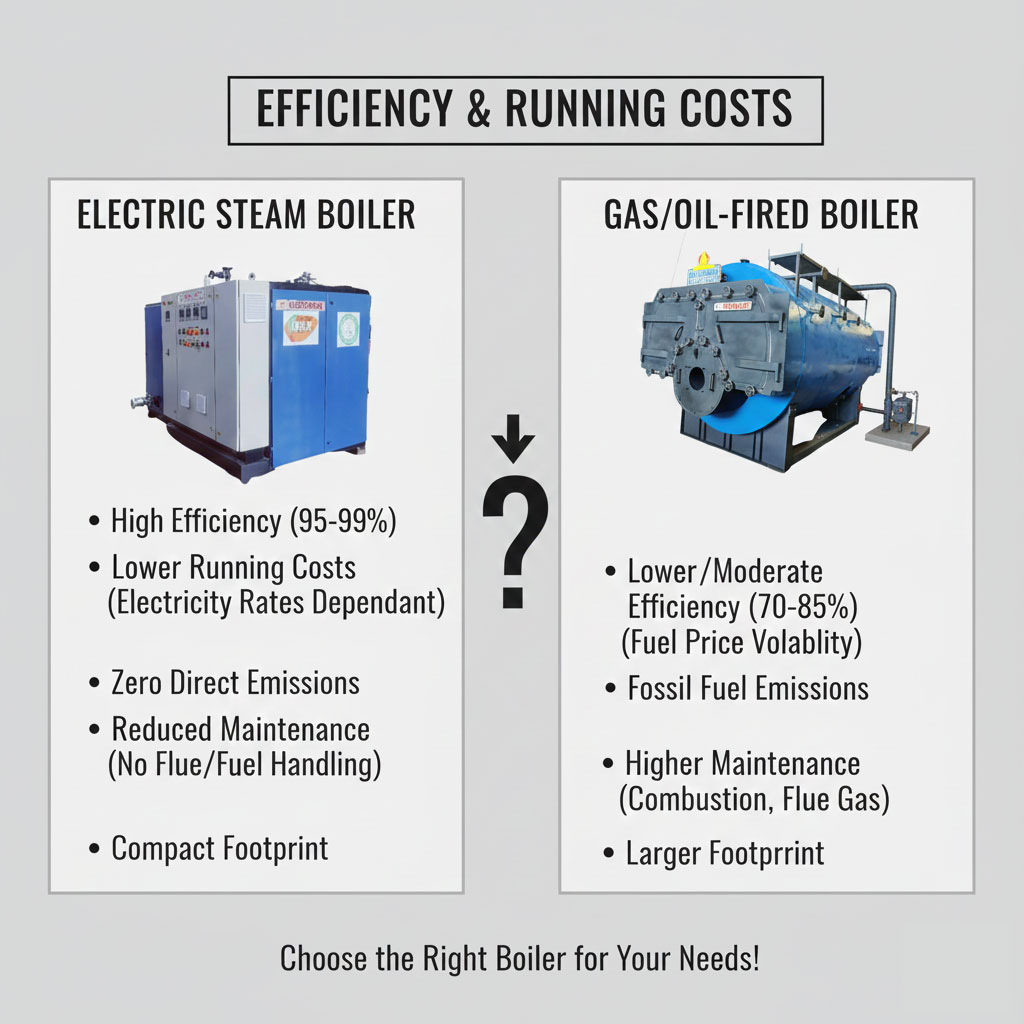

In the dynamic landscape of Indian industry, choosing the right steam boiler isn’t just about initial purchase price; it’s about long-term operational efficiency and the total cost of ownership. For decades, industries have relied on traditional fuel-fired boilers, but with evolving energy markets and environmental concerns, electric steam boilers are rapidly gaining traction.

At Indianboilers.com, we offer both cutting-edge solutions: our ELECTROMAX Electric Steam Boiler and the robust STEAMJET Oil/Gas Fired Steam Boiler. Let’s break down how these two technologies stack up when it comes to efficiency and running costs.

Efficiency: A Deeper Look

When we talk about boiler efficiency, we’re essentially asking: “How much of the input energy is converted into usable steam?”

1. Electric Steam Boilers (e.g., ELECTROMAX): The Near-Perfect Conversion

- Operational Efficiency: 98-99%

- This is where electric boilers truly shine. With an ELECTROMAX, almost all the electrical energy consumed is directly converted into heat within the water, producing steam.

- There are no flue gas losses (heat escaping up a chimney), no radiation losses from a hot combustion chamber, and no standby losses from maintaining a flame.

- Steam is generated almost instantly upon demand, minimizing energy waste during startup and shutdown cycles.

2. Fuel-Fired Steam Boilers (e.g., STEAMJET): The Combustion Challenge

- Operational Efficiency: 80-90% (typically)

- Fuel-fired boilers, like our STEAMJET series, burn fossil fuels (LDO, HSD, Natural Gas, LPG, etc.) to heat water. While highly effective, the combustion process inherently leads to some energy loss.

- Flue Gas Losses: A significant portion of heat is lost with the exhaust gases that go up the chimney.

- Radiation Losses: Heat radiates from the hot surfaces of the boiler shell and combustion chamber.

- Blowdown Losses: Energy is lost during the boiler blowdown process, necessary to remove dissolved solids.

- Achieving efficiencies above 90% in fuel-fired boilers usually requires advanced features like economizers and air preheaters, adding to the initial cost.

Key Takeaway on Efficiency: On paper, ELECTROMAX electric boilers offer a significantly higher operational efficiency due to the direct conversion of electrical energy.

Running Costs: Beyond the Fuel Price

This is where the comparison gets more nuanced, as multiple factors contribute to the overall running cost.

1. Fuel/Energy Cost:

- Electric Boilers (ELECTROMAX):

- Pros: Electricity prices are generally stable and predictable in the short term, especially for industrial tariffs. No need for fuel storage or associated logistics.

- Cons: Electricity can be more expensive per unit of energy (kWh) compared to the thermal equivalent of some fossil fuels. This is often the primary concern for potential buyers. However, many states in India offer subsidized industrial power tariffs, or companies can leverage renewable energy sources (solar, wind) to generate their own power, dramatically reducing running costs.

- Fuel-Fired Boilers (STEAMJET):

- Pros: Historically, fossil fuels could offer a lower energy cost per thermal unit in some regions.

- Cons: Fuel prices (oil, gas) are highly volatile, subject to international markets, geopolitical events, and domestic taxation. This makes long-term cost prediction challenging. Significant costs are also incurred for fuel procurement, transportation, storage infrastructure, and handling.

2. Maintenance Costs:

- Electric Boilers (ELECTROMAX):

- Lower Maintenance: With no combustion, there are no burners to clean, no soot to remove from heat exchange surfaces, and no exhaust systems to maintain. The primary components are heating elements, contactors, and control systems, leading to simpler, less frequent, and generally cheaper maintenance.

- No Refractory Maintenance: Eliminates the need for costly refractory repairs.

- Fuel-Fired Boilers (STEAMJET):

- Higher Maintenance: Requires regular cleaning of burners, flues, and heat transfer surfaces to maintain efficiency. Refractory lining in the combustion chamber needs periodic inspection and repair. Fans, pumps, and other auxiliary equipment may also require more intensive maintenance.

3. Environmental & Regulatory Costs:

- Electric Boilers (ELECTROMAX):

- Zero On-Site Emissions: This is a huge advantage. No NOx, SOx, or particulate matter is released on-site. This eliminates the need for expensive emission control equipment, regular stack monitoring, and often simplifies environmental clearances. Contributes to a greener corporate image.

- Fuel-Fired Boilers (STEAMJET):

- Emission Compliance: Requires adherence to stringent emission norms. This can involve significant investment in flue gas treatment systems (e.g., scrubbers), continuous emission monitoring systems (CEMS), and ongoing regulatory compliance costs and reporting.

4. Space & Installation Costs:

- Electric Boilers (ELECTROMAX):

- Compact Footprint: Generally smaller and more compact, requiring less boiler room space.

- Simpler Installation: No need for chimneys, fuel lines, or large ventilation systems, reducing installation complexity and cost.

- Fuel-Fired Boilers (STEAMJET):

- Larger Footprint: Requires space for the boiler, fuel storage tanks, chimney, and auxiliary equipment.

- More Complex Installation: Involves civil work for foundations, chimney erection, fuel line installation, and more extensive piping and ventilation.

The Verdict: It Depends on Your Priorities

There’s no one-size-fits-all answer.

- Choose ELECTROMAX Electric Steam Boiler if:

- You prioritize high efficiency, zero on-site emissions, ultra-clean steam, and minimal maintenance.Your facility has access to favorable industrial electricity tariffs or uses renewable energy.You operate in industries with stringent hygiene requirements (Food, Pharma, Biotech) or where an open flame is a safety concern (Chemicals, R&D).

- You need quick startup/shutdown and precise control.

- Choose STEAMJET Oil/Gas Fired Steam Boiler if:

- You have access to a very economical and stable supply of natural gas or other fossil fuels.You require very high steam capacities where the electrical infrastructure might be prohibitively expensive to upgrade.

- Your primary concern is the lowest possible cost per thermal unit of fuel, even if it comes with higher maintenance and environmental overheads.

Making the Right Choice with IndianBoilers.com

At Indianboilers.com, we are committed to helping you find the most efficient and cost-effective solution for your specific needs. Whether it’s the unparalleled efficiency of our ELECTROMAX Electric Steam Boiler or the proven power of our STEAMJET Oil/Gas Fired Steam Boiler, our experts can provide a detailed ROI analysis tailored to your operational demands and local energy costs.

Ready to optimize your steam generation? Contact us today for a personalized consultation!

What is the difference between your ELECTRON and ELECTROMAX series?

- ELECTRON: Our specialized range of Non-IBR Electric Boilers, ideal for small-scale applications.

- ELECTROMAX: Our heavy-duty IBR-certified Electric Boilers designed for high-pressure and high-volume industrial steam requirements.

Why is IBR certification necessary for electric boilers?

In India, if a boiler’s water capacity is above 25 liters or if it operates above a certain pressure, it must be IBR-certified. This ensures the unit meets stringent safety standards for material quality, welding, and pressure-bearing capacity.

Do I need to register my Electric IBR Boiler with the local authority?

Yes. Every IBR-certified boiler must be registered with the State Boiler Inspectorate. At indianboilers.com, we provide all the necessary IBR folders and documentation to make this process seamless for you.

How often does an IBR Electric Boiler need inspection?

According to the law, an IBR boiler must undergo an annual open inspection by a government boiler inspector to renew its fitness certificate.

What is the efficiency of the ELECTROMAX series?

Our Electric IBR Boilers are exceptionally efficient, converting nearly 98% to 99% of electrical energy into steam. Unlike fuel-fired boilers, there is no heat loss through a chimney.

What is the capacity range available at Indianboilers.com?

Our ELECTROMAX series typically starts from 100 kg/hr and can go up to 2,000 kg/hr or more, depending on your specific industrial steam demand.

How much time does it take to reach full steam pressure?

One of the key benefits is speed. Because the heating elements are directly submerged, an electric boiler can reach working pressure in roughly 10–15 minutes from a cold start.

What is the maximum working pressure for these units?

Standard industrial models handle pressures up to 10.54 kg/cm². However, we can custom-build IBR units for high-pressure requirements up to 21 kg/cm².

Can the steam output be modulated?

Yes. Our boilers use a multi-stage heating system. As steam demand fluctuates, the system automatically switches heating stages on or off, ensuring you only use the power you need.

Which industries require IBR Electric Boilers?

They are the preferred choice for high-purity and high-safety environments:

- Pharmaceuticals: For sterilization and reactors.

- Food & Dairy: For pasteurization and Clean-in-Place (CIP).

- Chemical Plants: For high-pressure process heating.

- Hospitals: For large-scale autoclaves and laundry.

Does an electric boiler require a chimney?

No. Since there is no combustion of fuel, there is no smoke or exhaust gas. This eliminates the need for tall chimneys, air pollution permits, and expensive ducting.

Is it true that electric boilers are quieter?

Yes. Without burners, blowers, or fuel pumps, the ELECTROMAX operates almost silently, making it ideal for facilities located near residential areas or sensitive work environments.

What are the key safety features?

Our IBR boilers are equipped with:

- Dual Safety Valves: To prevent over-pressurization.

- Mobrey Water Level Controller: For precise low-water cut-off protection.

- Over-current Protection: To safeguard the high-grade heating elements.

How do I maintain the heating elements?

The biggest enemy of electric boilers is scale buildup. Using a water softener is mandatory. Beyond that, periodic checking of the electrical terminals and "blow-down" to remove sludge is all that is required.

How long is the lifespan of an ELECTROMAX boiler?

With regular IBR inspections and proper water treatment, our boilers are built to last 15 to 20 years. The heating elements can be easily replaced individually without replacing the entire unit.

What is the price of an Industrial Electric IBR Steam Boiler?

Pricing depends on the kW rating and steam capacity. For an IBR-certified unit:

- Small units (100–200 kg/hr) typically start from ₹4,50,000 to ₹1,000,000.00.

- Medium to High capacity units (500–1000 kg/hr) can range from ₹1,000,000.00 to ₹25,00,000+.

- Note: Prices vary based on the automation grade (PLC/HMI) and current material costs.

Why is an IBR boiler more expensive than a Non-IBR one?

IBR units use specialized boiler-grade steel (e.g., SA 516 Gr. 70), undergo third-party radiographic testing of all welds, and include government inspection fees and certified safety mountings.

What is the typical ROI for switching to electric steam?

While electricity costs per unit can be higher than coal, the ROI is achieved through zero labor costs (no fireman needed), reduced maintenance, higher efficiency, and the elimination of fuel storage and handling.

How can I get a custom quote for my plant?

Visit the Contact Us page on indianboilers.com or reach out to our technical team on WhatsApp. Please provide your required Steam Output (kg/hr) and Working Pressure for an accurate proposal.