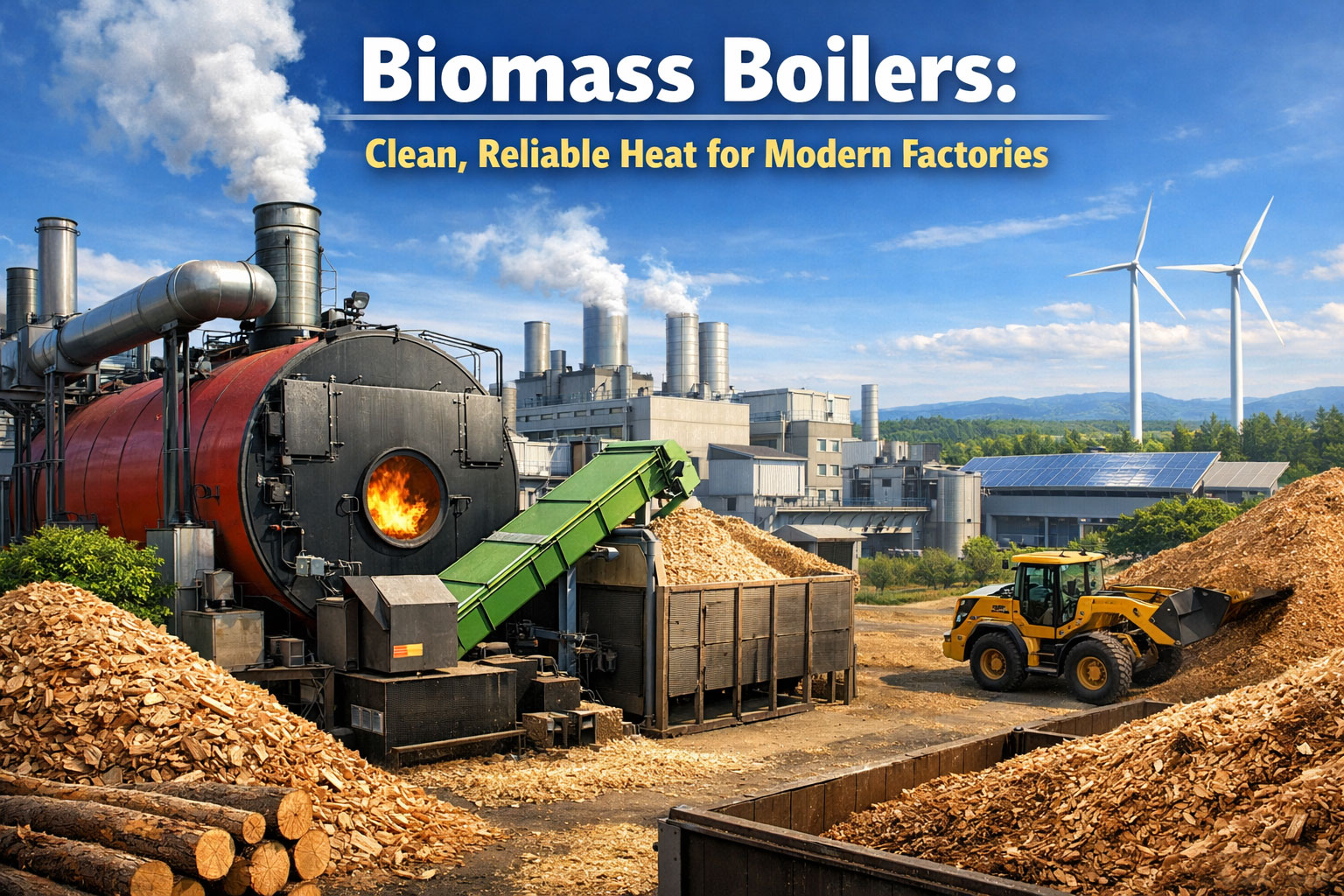

Biomass Boilers: Clean, Reliable Heat for Modern Factories

In the traditional industrial imagination, “biomass” often conjures images of manual labor, inconsistent heat, and smoky chimneys. However, the reality of 2026 is radically different. Today’s Biomass Boilers are high-tech, digitally controlled, and hyper-efficient thermal powerhouses.

For the modern factory manager in India—facing pressure from both global supply chain ESG (Environmental, Social, and Governance) mandates and rising coal prices—biomass is no longer a “back-up” fuel. It is the backbone of reliable, clean, and cost-effective steam generation.

At IndianBoilers.com, we are redefining how factories heat their processes. Here is the definitive guide to why biomass is the “clean energy” of choice for the modern factory.

1. The Myth of “Dirty” Biomass vs. The Modern Reality

The primary hesitation many plant engineers have regarding biomass is the perceived “mess.” Modern engineering has solved these legacy issues through three core pillars:

A. Precision Combustion (The Science of O2 Control)

Modern biomass boilers use Oxygen (Lambda) Sensors to monitor exhaust gases in real-time. By automatically adjusting the Variable Frequency Drives (VFDs) on the Forced Draft (FD) and Induced Draft (ID) fans, the boiler maintains a perfect air-to-fuel ratio.

- Result: No unburnt carbon (black smoke) and maximum heat release.

B. Advanced Multi-Cyclone & Bag Filters

Environmental compliance is non-negotiable. Modern factories now utilize Pulse-Jet Bag Filters that capture 99.9% of particulate matter, ensuring the “smoke” leaving the chimney is largely harmless water vapor and CO2.

C. Automated Ash Handling

Gone are the days of manual raking. Submerged belt conveyors or pneumatic ash handling systems automatically transport residue from the furnace to sealed silos, keeping the boiler house as clean as a pharmaceutical lab.

2. Technical Architecture: How Modern Biomass Boilers Achieve Reliability

For a factory running 24/7, “Reliability” is the only metric that matters. If the steam stops, the production line stops.

The Hybrid Design (Water-cum-Fire Tube)

At IndianBoilers.com, we often recommend the Hybrid design for modern factories.

- Water-Wall Furnace: The combustion chamber is surrounded by water-filled tubes, providing a massive radiant heat surface area. This allows for quick steam raising (fast start-up).

- Fire-Tube Shell: The second and third passes occur within a shell, providing a large “thermal flywheel” or water inventory. This handles sudden “peak loads” in the factory without a drop in pressure.

Fuel Versatility: The “Multi-Fuel” Advantage

Modern factories cannot be beholden to a single supplier. Our combustion chambers are designed to be “fuel-agnostic,” meaning they can switch between:

- Rice Husk (Granular, high silica)

- Wood Chips (High moisture, high energy)

- Briquettes/Pellets (High density, low ash)

- Agro-Waste (Mustard stalk, corn cobs)

3. The Digital Boiler: IoT and Industry 4.0

The “Modern Factory” is a data-driven environment. Biomass boilers have joined this ecosystem through Smart Monitoring Systems.

| Feature | Function | Benefit for the Factory |

| Remote Telemetry | View boiler status on a smartphone. | Management can monitor fuel consumption from anywhere. |

| Predictive Maintenance | Sensors detect vibration in bearings or pumps. | Fix a part before it fails and causes a shutdown. |

| Automated Logbooks | Digital recording of steam output and fuel input. | Accurate “Cost per kg of Steam” calculation for accounting. |

4. Sustainability: Meeting the “Net-Zero” Mandate

If your factory exports products to Europe or the USA, you are likely facing CBAM (Carbon Border Adjustment Mechanism) or similar carbon taxes.

Why Biomass is the “Green Ticket”:

- Closed Carbon Cycle: The CO2 emitted by a biomass boiler was absorbed by the plant just months prior. Unlike coal (which releases “fossilized” carbon from millions of years ago), biomass is part of the current atmospheric carbon cycle.

- Reduction in Scope 1 Emissions: Switching from Furnace Oil to Biomass can reduce a factory’s reportable carbon footprint by up to 90%, instantly making the brand more attractive to global buyers.

5. Economic Stability in a Volatile World

Fossil fuel prices are tied to global geopolitics. A conflict in the Middle East or a shipping disruption in the Suez Canal can double your oil or gas bill overnight.

Biomass is Decentralized. The fuel for your boiler is likely grown within a 100km radius of your factory. This creates a “Local Energy Loop”:

- Price Stability: Agro-waste prices are predictable and tied to local harvest cycles, not global oil indexes.

- Forex Savings: Using local husk instead of imported coal helps the national economy and your company’s bottom line.

6. Real-World Application: Sector-Wise Reliability

Food & Beverage (F&B)

Modern F&B factories require “Food-Grade” steam. Biomass boilers equipped with sophisticated water treatment (RO + DM plants) ensure that the steam used in direct injection or jacketed kettles is of the highest purity.

Pharmaceuticals

In Baddi or Sikkim, where pharmaceutical hubs are located, “Clean Air” is a mandate. Biomass boilers with Electrostatic Precipitators (ESP) allow these plants to save millions in energy costs while adhering to the strictest air quality standards.

Textiles & Chemical Processing

These industries require massive amounts of “Process Heat.” The ability of a biomass boiler to provide a constant, high-pressure head of steam makes it superior to electrical heating or solar thermal for large-scale industrial use.

7. The Checklist: Upgrading to a Modern Biomass System

If you are currently operating an aging coal boiler or an expensive oil unit, here is how you modernize:

- Conduct a Steam Audit: How much steam do you actually need? Many factories “over-boiler,” leading to efficiency losses.

- Evaluate Fuel Logistics: Ensure you have the yard space for 15-30 days of biomass storage.

- Select the Right Grate: Don’t settle for a static grate. Look at Reciprocating or Traveling Grates for automated operation.

- Plan for Ash: Identify a local brick manufacturer or cement plant that can utilize your ash, turning a waste product into a small revenue stream.

Conclusion: The Reliable Path Forward

The modern factory is characterized by three things: Efficiency, Sustainability, and Data. Biomass boilers, as engineered by IndianBoilers.com, check all three boxes. They offer the reliability of traditional fuels with the carbon-neutral profile of the future. By investing in biomass, you aren’t just buying a boiler; you are securing your factory’s energy independence for the next two decades.