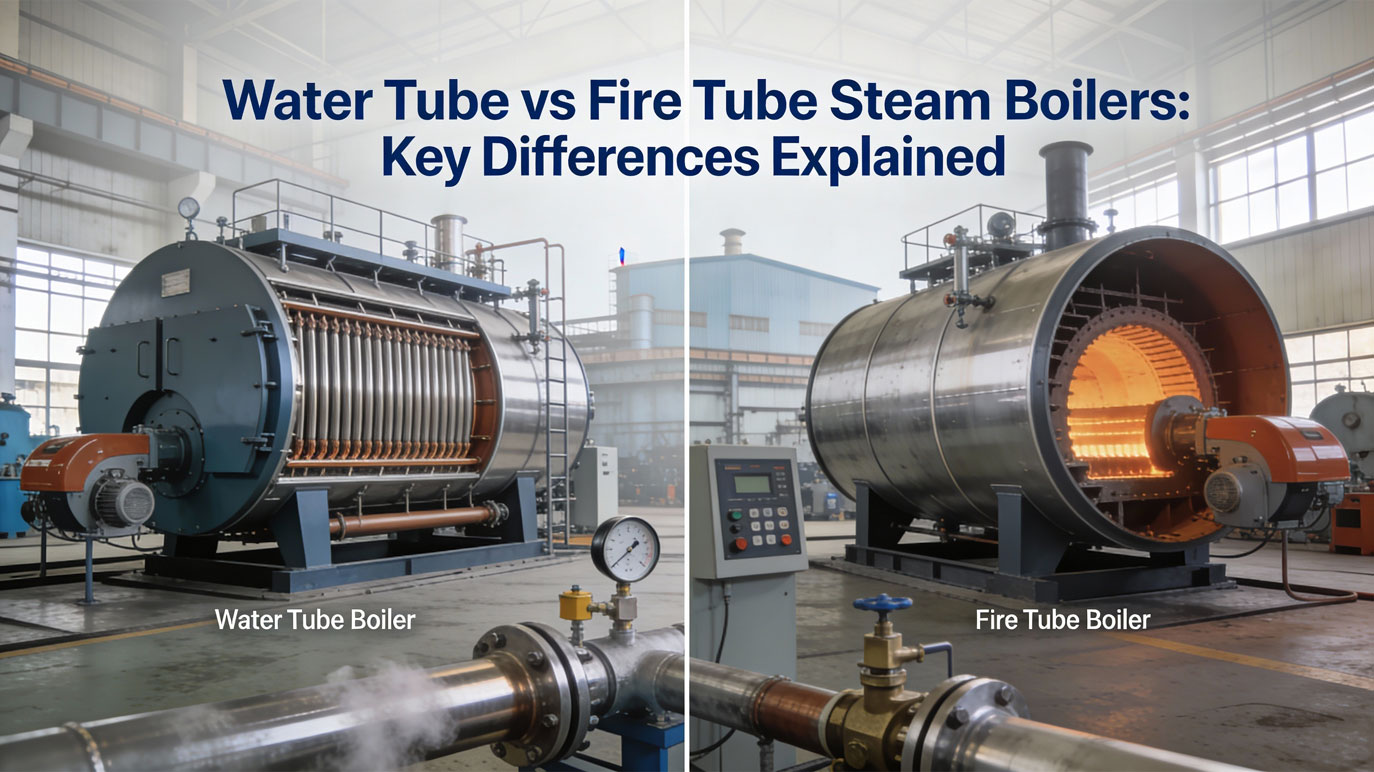

Water Tube vs Fire Tube Steam Boilers: Key Differences Explained

Steam boilers are essential for industrial operations across India, powering everything from textile mills to food processing plants. Among the most common designs, water tube and fire tube steam boilers stand out for their reliability and efficiency. Understanding their key differences helps Indian businesses like those served by indianboilers.com select the right model for high-pressure demands or cost-effective operations.

This comprehensive guide explores the fundamental distinctions between water tube and fire tube steam boilers. It covers design principles, performance metrics, applications in Indian industries, and practical advice for maintenance and selection. By the end, you’ll know which boiler suits your manufacturing needs, whether for small-scale MSMEs or large power plants.

Core Design Principles

Fire tube boilers feature hot combustion gases passing through tubes submerged in a surrounding water-filled shell. This setup heats the water indirectly as gases flow inside the tubes, generating steam in the upper drum. The design is straightforward, making it ideal for simpler installations where space and budget are priorities.

Water tube boilers reverse this process, with water circulating inside the tubes while hot gases surround them externally. Steam forms quickly within the tubes and rises to a steam drum, enabling rapid heat transfer. This configuration supports higher pressures and is common in modern Indian factories requiring consistent high-output steam.

The inverted heat flow in water tube designs allows for better control over steam quality and volume. Fire tube systems rely on a large water volume for heat storage, providing stability during minor load changes.

Key Comparison Table

| Aspect | Fire Tube Boiler | Water Tube Boiler |

|---|---|---|

| Heat Flow | Gases inside tubes, water outside | Water inside tubes, gases outside |

| Operating Pressure | Up to 20 bar | Up to 100+ bar |

| Steam Generation Rate | Low (up to 9 tonnes/hour) | High (up to 450 tonnes/hour) |

| Floor Space Required | More (8 m² per tonne/hour) | Less (5 m² per tonne/hour) |

| Startup Time | Slower (30-60 minutes) | Faster (5-15 minutes) |

| Water Volume | High, better heat retention | Low, quicker response |

| Efficiency | Around 75% | Up to 90% |

| Load Fluctuation Handling | Poor, stable loads only | Excellent, handles variations |

| Maintenance Cost | Low | Higher due to complexity |

| Typical Size | Smaller capacities | Larger, scalable for power plants |

Performance and Efficiency Breakdown

Fire tube boilers excel in low-to-medium pressure applications, such as small Indian rice mills or garment factories. Their large water capacity acts as a thermal buffer, maintaining steam supply during brief fuel interruptions. However, this also means slower recovery from pressure drops, limiting them to steady-state operations.

Water tube boilers shine in high-demand scenarios, like pharmaceutical plants or chemical processing units in India. The thin water layer in tubes heats up rapidly, producing dry steam with minimal carryover. They handle sudden load surges better, with turndown ratios allowing precise modulation—crucial for energy-intensive industries facing variable production schedules.

Efficiency gains in water tube designs come from superior heat transfer via convection and conduction. Indianboilers.com models incorporate advanced fins on tubes to maximize this, reducing fuel consumption by 15-20% compared to older fire tube units. For biomass or agro-waste fuels common in India, water tube boilers offer cleaner combustion and lower emissions.

Applications in Indian Industries

In India’s textile sector, fire tube boilers power dyeing and drying processes in compact setups. Their simplicity suits MSMEs in Tirupur or Surat, where quick installation and low upfront costs matter. Models like the scotch marine fire tube from indianboilers.com handle 1-5 tonnes/hour efficiently.

Water tube boilers dominate power generation and heavy manufacturing. Refineries in Gujarat or steel plants in Jharkhand rely on them for 200+ bar pressures. Their modular design allows scaling—add drums or banks of tubes for growing operations, aligning with India’s Make in India push for expandable infrastructure.

Food processing plants in Punjab favor water tube for hygiene, as faster steaming reduces bacterial risks. Fire tube options work for batch cooking in smaller units, but water tube’s quick response prevents production delays during peak seasons.

Advantages and Disadvantages

Fire tube boilers offer affordability and ease of use. A skilled operator can manage one with minimal training, and transportation is straightforward due to compact builds. Disadvantages include explosion risks from low-pressure limits and poor scalability for mega-projects.

Water tube boilers provide unmatched safety at high pressures, thanks to smaller water volumes per tube—reducing blast potential. They support superheated steam for turbines, vital for cogeneration in Indian distilleries. Drawbacks involve higher initial investment and the need for purified feedwater to prevent scaling.

For Indianboilers.com clients, hybrid considerations like D-type water tube or horizontal return fire tube balance these traits. Retrofitting fire tube units with economizers boosts efficiency without full replacement.

Installation and Maintenance Guide

Installing a fire tube boiler involves a sturdy foundation for its weight, with space for tube cleaning access. Connect to Indian-standard IBR-approved piping, and commission with hydrostatic tests at 1.5x operating pressure. Annual inspections focus on tube ends for soot buildup.

Water tube setups require precise tube alignment and expansion joints. Use non-IBR for pressures under 3.5 kg/cm² in small plants, but IBR certification for larger ones. Maintenance emphasizes water chemistry—maintain pH 10-11 to avoid corrosion.

Both types benefit from automated controls. Indianboilers.com integrates PLC systems for blowdown, feedwater, and flame monitoring, cutting downtime by 40%.

Cost Analysis for Indian Buyers

Fire tube boilers start at ₹10-20 lakhs for 1 TPH models, scaling to ₹50 lakhs for 5 TPH. Operating costs stay low at ₹3-4 per kg steam with efficient fuels like rice husk.

Water tube units range ₹30 lakhs to ₹2 crores, but ROI hits in 18-24 months via fuel savings. Government subsidies under MSME schemes offset 15-25% for energy-efficient models.

Factor in lifecycle: water tube’s 20-25 year span vs. fire tube’s 15-20, plus lower emissions fines under India’s pollution norms.

Future Trends in Steam Boilers

India’s shift to renewables favors biomass-fired water tube boilers, integrating with solar preheaters for 95% efficiency. IoT sensors enable predictive maintenance, alerting to tube leaks via apps.

Hybrid fire-water tube designs emerge for mid-sized plants, combining fire tube stability with water tube speed. Indianboilers.com leads with non-IBR wood-fired options for rural industries.

As EPC norms tighten, modular water tube boilers promise plug-and-play scalability for Atmanirbhar Bharat factories.

Selecting the Right Boiler for Your Plant

Assess pressure needs: under 20 bar? Go fire tube. Above? Water tube. Calculate steam demand—fluctuating loads demand water tube responsiveness.

Consult indianboilers.com for custom audits, including fuel analysis and site surveys. Prioritize IBR compliance for safety and resale value.

In summary, fire tube boilers suit stable, low-pressure Indian operations, while water tube excel in demanding, high-output scenarios. Choose based on your industry’s scale and efficiency goals to optimize performance.