The Rice Mill and Textile sectors are the twin pillars of India’s processing industry, both sharing a critical dependency on one thing: reliable, low-cost steam. For years, this steam was generated by costly and polluting fossil fuels. Today, the economic and environmental necessity to switch has never been stronger.

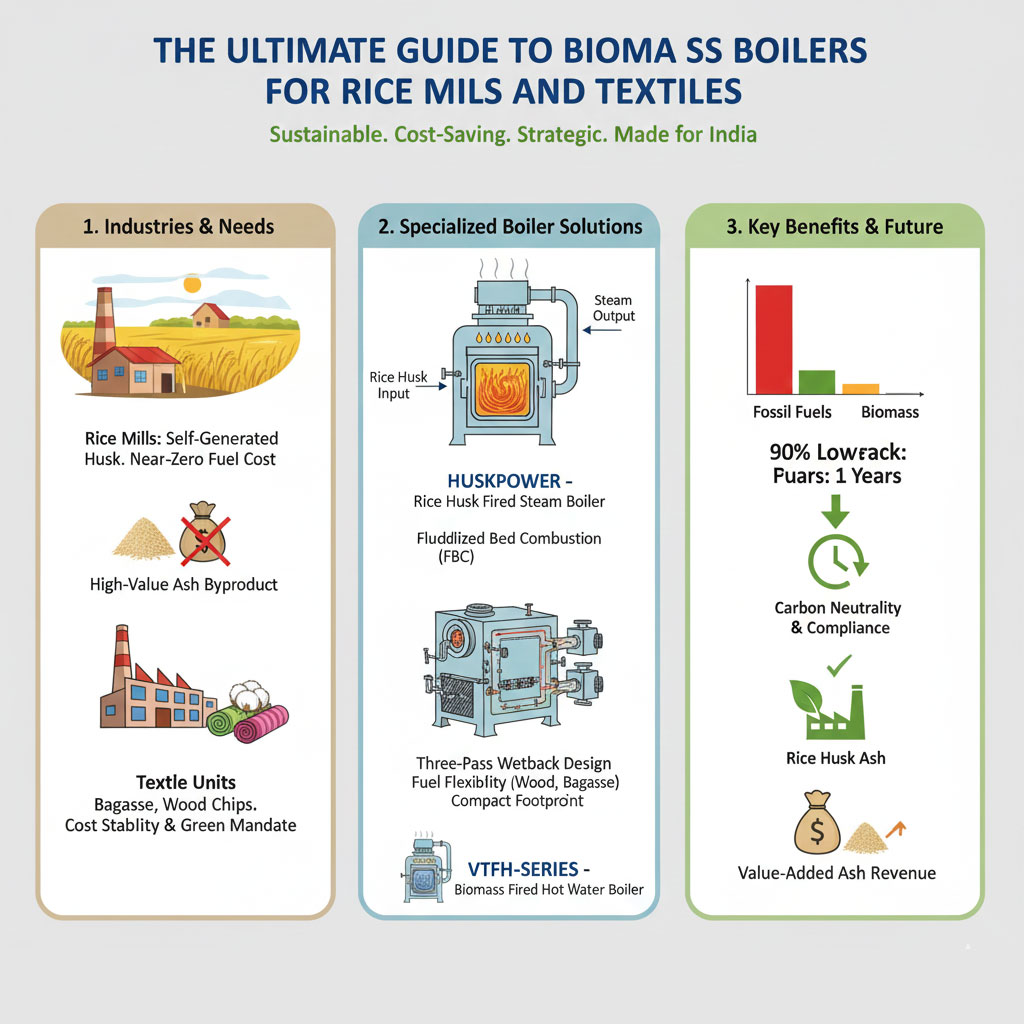

At IndianBoilers.com, we recognize the unique demands of these industries. This guide outlines how specialized Biomass Steam Boilers—specifically our HUSKPOWER and COMCUBE series—are engineered to transform the operations of rice mills and textile units, guaranteeing substantial fuel savings and superior efficiency.

Why Biomass is Essential for Rice Mills and Textiles

Both industries operate on high volumes and slim margins, making energy costs a major competitive factor.

| Sector | Primary Steam Use | Ideal Fuel Source | Cost Imperative |

| Rice Mills | Parboiling, Drying, Conditioning | Rice Husk (Self-Generated Waste) | Eliminate fuel and waste disposal costs |

| Textile Units | Dyeing, Sizing, Printing, Finishing | Bagasse, Wood Chips, Pellets | Stabilize costs and meet global sustainability mandates |

The Cost-Saving Factor: Near-Zero Fuel for Rice Mills

For rice mills, the decision is straightforward: rice husk is a near-zero cost fuel. By installing a dedicated Rice Husk Fired Boiler, mills eliminate the cost of buying external fuel and the cost of disposing of the husk waste. The return on investment (ROI) is often measured in months, not years.

Solution 1: HUSKPOWER – The Dedicated Rice Husk Fired Steam Boiler

The HUSKPOWER – Rice Husk Fired Steam Boiler is our flagship solution, engineered specifically to address the unique challenges of rice husk.

A. The Challenge: High Silica Ash

Rice husk contains 18%-25% silica ash, which is highly abrasive and tends to fuse or clump into slag at high temperatures. Traditional boilers struggle with this, leading to low efficiency, high maintenance, and frequent shutdowns.

B. The HUSKPOWER Advantage

The HUSKPOWER system overcomes these hurdles through specialized design:

- Fluidized Bed Combustion (FBC): This technology creates a turbulent bed of inert material (e.g., sand) that quickly and completely burns the husk at lower, controlled temperatures. This prevents ash fusion and slag formation, ensuring continuous, high-efficiency operation.

- Specialized Air Control: Meticulous control over primary and secondary air prevents carryover and minimizes the risk of tube erosion from the abrasive silica, maximizing boiler lifespan.

- High-Value Ash Handling: The resulting Rice Husk Ash (RHA) is collected cleanly and can be sold for use in cement or construction, creating an additional revenue stream.

Ideal for: Rice Mills, Agro-Processing Plants, and any industry with access to a dedicated rice husk supply.

Solution 2: COMCUBE – The Versatile Biomass Steam Boiler

The COMCUBE – Biomass Steam Boiler is designed for textile units and general industries that require fuel flexibility and a high thermal efficiency in a compact footprint.

A. The Textile Demand

Textile units often operate in clusters and require steam from multiple biomass sources like bagasse (from nearby sugar mills), wood chips, or imported pellets. They demand a boiler that can maintain steady pressure despite variations in fuel type.

B. The COMCUBE Advantage

The COMCUBE excels in flexibility and performance:

- Three-Pass, Fully Wetback Design: The three-pass design maximizes heat transfer surface area, ensuring thermal efficiencies often exceeding 80%. The fully wetback furnace minimizes heat loss and extends boiler longevity.

- Optimized Grate Design: The combustion system is typically designed with a robust grate that efficiently burns medium-density biomass like briquettes, pellets, and chopped wood, allowing the unit to adapt to the lowest-cost available fuel.

- Compact Footprint: Its design is ideal for textile units in space-constrained industrial estates, providing high output without demanding large boiler house space.

Ideal for: Textile Units, Food Processing Plants, Breweries, and any factory requiring fuel flexibility across various agro-wastes.

The Role of Hot Water: VTFH-SERIES

While steam is the core requirement, many parts of both the rice mill (e.g., conditioning) and textile process (e.g., lower temperature washing, utility heating) use hot water.

Our VTFH-SERIES – Biomass Fired Hot Water Boiler provides a high-efficiency alternative to generating hot water directly, often eliminating the need for steam-to-water heat exchangers, simplifying the system, and further reducing operational costs.

Conclusion: Strategic Investment for a Sustainable Future

For rice mills, a HUSKPOWER boiler transforms waste into profit. For textile units, a COMCUBE boiler guarantees low, stable energy costs essential for competing globally.

Switching to a specialized biomass boiler from IndianBoilers.com is a strategic investment that guarantees operational cost reduction, compliance with green mandates, and a sustainable competitive advantage for years to come.

Secure the future of your plant with India’s most efficient biomass boiler technology.

Contact IndianBoilers.com today for a detailed consultation tailored to your specific steam demands and fuel sources.