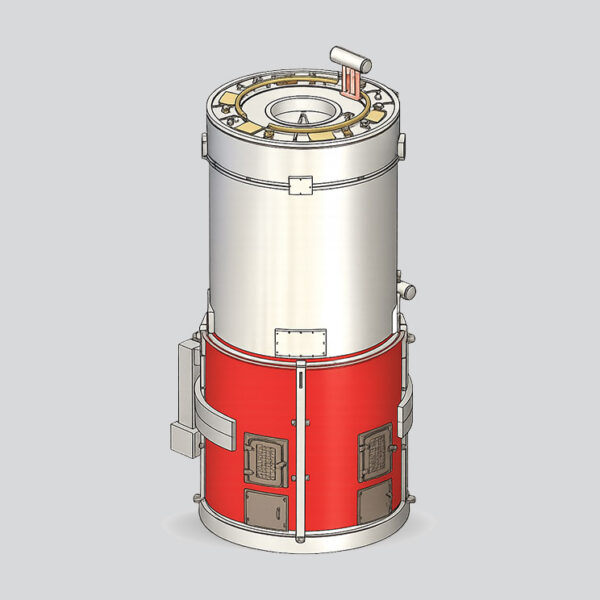

Biomass Fired Hot Water Boiler (VTFH-SERIES)

Cost-Effective, Sustainable, and High-Performance Heating

VTFH is a vertical four-pass, smoke tube hot water boiler that can be fired on wood and Biomass Briquette. The hot water boiler has high efficiency and is user friendly and has automatic fuel feeding system. The front end and shell rear end are closed with the help of tube sheets. The flue tubes are fitted between the front and rear tube sheet. Combustion furnace is fitted at bottom side of main heat exchanger.

The VTFH-SERIES is a cutting-edge Vertical Four-Pass Smoke Tube Hot Water Boiler designed by Indian Boilers to provide reliable heating using renewable biomass fuels. Specifically engineered for industrial applications, this boiler offers a compact footprint and exceptional fuel efficiency, making it the ideal choice for businesses looking to reduce their carbon footprint and operational costs.

Biomass fired hot water boilers use renewable agricultural and wood-based fuels to generate reliable hot water for process heating and comfort applications while significantly cutting energy costs and emissions. They are ideal for Indian industries, commercial buildings, and institutions looking to shift from diesel, LPG, or electricity to a greener and more economical option.

What is a biomass hot water boiler?

A biomass fired hot water boiler burns solid biofuels such as wood, briquettes, pellets, rice husk, or agro-waste to heat water up to typically 85–95 °C for closed-loop heating systems. The unit includes a combustion chamber, heat exchanger, water jacket, insulation, and controls to deliver constant hot water at the required temperature and flow rate.

Fuel options and compatibility

These boilers support a wide range of locally available fuels including wood logs, wood chips, biomass briquettes, rice husk, sawdust, and other agro residues, depending on the grate and feeding design. Using regionally sourced biomass reduces dependence on imported fossil fuels and converts agricultural waste into a valuable energy resource.

Key Features & Advantages

- Vertical Four-Pass Design: Enhances heat transfer and optimizes thermal efficiency within a minimal footprint.

- Eco-Friendly Fueling: Fully compatible with Wood Logs and Biomass Briquettes, utilizing carbon-neutral energy sources.

- User-Friendly Operation: Features an automatic fuel feeding system (screw feeder) and easy-to-use controls for seamless daily management.

- Low Maintenance: Designed with accessible tube sheets for quick cleaning and long-term durability.

- Efficient Heat Exchange: Low stack temperatures at the hot water outlet ensure that energy is utilized to its maximum potential.

- High Performance: Equipped with electrically driven water circulation pumps for steady and reliable flow.

Applications & Industries

The VTFH-Series is the perfect heating solution for a variety of sectors requiring consistent hot water, including:

- Textiles & Garment Washing

- Food Processing & Dairies

- Hotels & Hospitality (Heating & Laundry)

- Chemical & Pharma Plants

- Hospitals & Large Institutions

Operating Range

- Capacity : 50000 Kcal/Hr. to 3 lac Kcal/Hr.

- Fuel : Wood Log, Biomass Briquette, Crushed Briquette, Rice Husk, and Coal.

- Temperature : Up to 90°C (Standard) / up to 95°C/150°C (Optional range)

Technical Specifications

| Specification | Unit | VTFH-400 | VTFH-600 | VTFH-800 | VTFH-1000 | VTFH-1500 | VTFH-2000 | VTFH-2500 | VTFH-3000 |

|---|---|---|---|---|---|---|---|---|---|

| General | |||||||||

| Maximum heat output | M. Kcal/hr | 0.4 | 0.6 | 0.8 | 1.0 | 1.5 | 2.0 | 2.5 | 3.0 |

| Maximum working temperature | °C | 95/150 | 95/150 | 95/150 | 95/150 | 95/150 | 95/150 | 95/150 | 95/150 |

| Hot water Rise temperature | °C | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 |

| Hot Water Inlet/ Outlet | MM | 80 | 80 | 100 | 100 | 120 | 150 | 150 | 200 |

| Heating surface area of heater | M² | 30 | 45 | 60 | 75 | 113 | 150 | 175 | 210 |

| Water holding capacity of heater | liter | 280 | 418 | 741 | 931 | 1750 | 2332 | 2721 | 3266 |

| Firing Mode | Automatic threw Scew feeder | ||||||||

| Type of Fuel | Fuel | Crushed Briquette, Rice husk, Coal | |||||||

| Boiler Efficiency | |||||||||

| On Crsushed briquette | % | 78 +/-2 | 78 +/-2 | 78 +/-2 | 78 +/-2 | 78 +/-2 | 78 +/-2 | 78 +/-2 | 78 +/-2 |

| On Rice Husk | % | 78 +/-2 | 78 +/-2 | 78 +/-2 | 78 +/-2 | 78 +/-2 | 78 +/-2 | 78 +/-2 | 78 +/-2 |

| On Coal | % | 78 +/-2 | 78 +/-2 | 78 +/-2 | 78 +/-2 | 78 +/-2 | 78 +/-2 | 78 +/-2 | 78 +/-2 |

| Fuel Consumption | |||||||||

| Crushed Briquette (4000) | Kg/hr | 128 | 192 | 256 | 321 | 481 | 641 | 801 | 962 |

| Rice Husk (3000) | Kg/hr | 171 | 256 | 342 | 427 | 641 | 855 | 1068 | 1282 |

| Caol (4500) | Kg/hr | 114 | 171 | 228 | 285 | 427 | 570 | 712 | 855 |

| Electrical Load | |||||||||

| Circulation Water Pump | H.P. | 10.00 | 12.50 | 15.00 | 20.00 | 25.00 | 30.00 | 40.00 | 50.00 |

| ID fan without BF | H.P. | 5.00 | 7.50 | 10.00 | 10.00 | 15.00 | 20.00 | 25.00 | 30.00 |

| FD fan with APH | H.P. | 5.00 | 7.50 | 10.00 | 10.00 | 15.00 | 20.00 | 25.00 | 30.00 |

| SFD fan with Motor | H.P. | 1.00 | 1.00 | 1.00 | 2.00 | 2.00 | 2.00 | 3.00 | 3.00 |

| Scew feeder | H.P. | 1.00 | 2.00 | 1.00 | 2.00 | 2.00 | 2.00 | 3.00 | 3.00 |

| Total Electric Load | H.P. | 22.00 | 30.50 | 37.00 | 44.00 | 59.00 | 74.00 | 96.00 | 116.00 |

| NOTE: In view of constant endeavors to improve our products, we reserve the right to alter or change above specifications without prior notice. | |||||||||

Why Buy from IndianBoilers.com?

As a globally respected leader in boiler manufacturing, Indian Boilers ensures every VTFH-Series unit is built with high-grade materials and precision engineering. Our commitment to innovation guarantees that you receive a boiler that is safe, efficient, and ready for “Plug and Play” commissioning.

Frequently Asked Questions

What fuels can I use in this boiler?

These boilers are highly versatile. You can use:

- Agro-Waste: Rice husk, mustard stalks, or groundnut shells.

- Wood Products: Sawdust, wood chips, and pellets.

- Processed Biomass: Biomass briquettes and pellets.

How is biomass "Carbon Neutral"?

Biomass releases only the amount of CO2 that the plant absorbed during its growth. Unlike fossil fuels which release "ancient" carbon, biomass is part of the current carbon cycle, making it a green energy solution.

Can I use rice husk in a hot water boiler?

Yes. While rice husk is more common in steam boilers, our specialized furnace designs can efficiently burn husk to produce large volumes of hot water for parboiling and other agro-processes.

What is the "Three-Pass" design in your hot water boilers?

The "Three-Pass" design forces hot combustion gases to travel the length of the boiler three times. This maximizes the time the gases spend in contact with the heat exchange surfaces, resulting in high thermal efficiency.

What is the typical efficiency of these boilers?

Our biomass hot water boilers achieve efficiencies of 78% to 82%. When fitted with an Economizer to recover waste heat from flue gases, efficiency can be boosted by an additional 3-5%.

Is the water circulation automatic?

Yes. The system uses a high-efficiency centrifugal pump to circulate water between the boiler and your process equipment (like radiators, kettles, or heat exchangers) in a closed or open loop.

How do you manage the ash produced?

Biomass produces more ash than oil or gas. Our boilers feature large, accessible ash pits for manual or semi-automatic removal, ensuring the furnace remains clean for optimal combustion.

Does it require a water softener?

Yes. To prevent scale formation inside the tubes, we strongly recommend using a water softener. Scale acts as an insulator, drastically reducing efficiency and eventually damaging the boiler.

Which industries benefit from Biomass Hot Water Boilers?

- Food & Dairy: For pasteurization and cleaning.

- Hotels & Hospitals: For central heating and laundry.

- Textiles: For washing and dyeing processes.

- Rice Mills: For parboiling and drying paddy.

Can this boiler replace an electric or oil-fired water heater?

Absolutely. If you have access to low-cost biomass, the "fuel bill" savings are often so high that the boiler pays for itself in less than a year.

Is it suitable for central heating in cold climates?

Yes. It is an excellent off-grid solution for large facilities like warehouses or worker colonies where a constant supply of hot water is required.

Does this boiler require IBR certification?

Hot water boilers operating below 100°C and within certain capacity limits are generally Non-IBR. This simplifies installation as you don't need annual government inspections or a certified boiler operator.

What safety controls are included?

Standard features include:

- High-Temperature Cut-off: To prevent the water from boiling.

- Low Water Level Alarm: To protect the tubes from dry firing.

- Pressure Relief Valves: To prevent over-pressurization.

How often should the boiler be cleaned?

Depending on the fuel, the smoke tubes should be cleaned with a wire brush every 1–2 weeks to remove soot, and the ash pit should be cleared daily.

What is the price of a Biomass Fired Hot Water Boiler?

Prices vary based on capacity (kcal/hr) and automation level. Approximate 2025 rates at indianboilers.com are:

- Small (up to 2 Lac kcal/hr): ₹500,000.

- Medium (5 Lac to 10 Lac kcal/hr): ₹4,00,000 – ₹8,50,000.

- Large (20 Lac+ kcal/hr): ₹12,00,000 and above.

How does the price compare to Oil/Gas boilers?

The initial capital cost of a biomass boiler is slightly higher due to the larger furnace and fuel handling needs. However, the running cost is 60–80% lower than Diesel (HSD) or FO boilers.

What factors impact the final quote?

The total Kcal/hr capacity, the choice of Manual vs. Automated feeding, and the inclusion of Pollution Control equipment (like Cyclone Dust Collectors) affect the final cost.

What is the typical ROI period?

For most Indian factories switching from Diesel or LPG to Biomass (Briquettes or Husk), the payback period is typically 6 to 10 months.

How do I get a custom quote for my plant?

Visit indianboilers.com and provide your required water temperature and flow rate (LPH). Our engineers will provide a detailed technical and commercial offer within 24 hours.

Reviews

There are no reviews yet.