STEAMAX – Sustainable Steam: Wood / Briquette Fired Steam Boiler

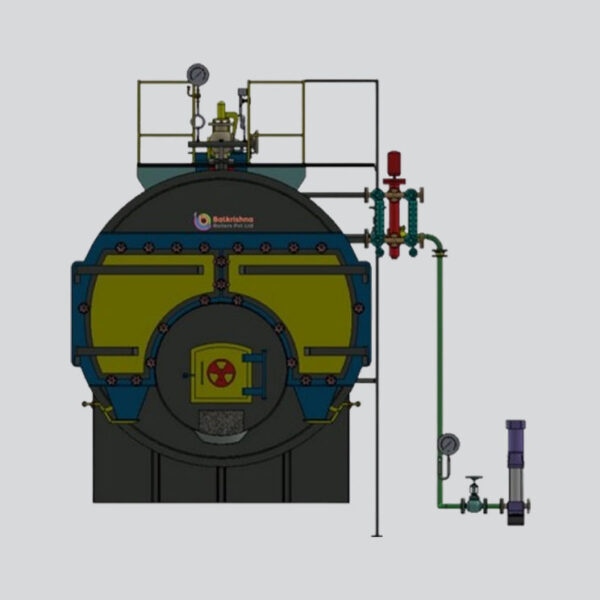

STEAMAX is a perfect solution where customer needs higher size of thermal oil heater and also has small/medium size of steam demand. STEAMAX is a four-pass horizontal package boiler, IBR designed and manufactured, Thermic fluid steam generator. It works on the heat exchange principle from hot thermal oil running through tubes immersed in water bath inside the shell.

In an era of rising fossil fuel costs and increasing environmental scrutiny, Industrial Wood / Briquette Fired Steam Boilers offer a powerful, cost-effective, and sustainable alternative for generating steam.

IndianBoilers.com provides robust, high-efficiency solid fuel boilers designed to harness the energy potential of biomass fuels, helping your business reduce operating costs and significantly lower its carbon footprint.

The Power of Biomass: Wood & Briquettes

Our solid fuel boilers are engineered for optimal combustion of agro-waste and renewable biomass, specifically:

- Wood: Chips, logs, and other wood waste.

- Briquettes: Compressed blocks made from agricultural residues (like rice husk, bagasse, groundnut shells) or wood waste, offering high calorific value and uniform firing.

This fuel flexibility makes our boilers ideal for industries looking to utilize locally sourced, inexpensive, and renewable resources.

Features & Operational Advantages

Designed for high performance and durability, our Wood/Briquette Fired Boilers are constructed to meet rigorous industrial standards, often including IBR approval for high-pressure applications.

| Feature | Operational Benefit | Key Terminology |

| Multi-Fuel Capability | Versatility to burn wood, briquettes, rice husk, or coal, securing your fuel supply and costs. | Multi-fuel steam boiler, Agro-waste boiler, Solid fuel boiler |

| High Thermal Efficiency | Optimized furnace and multi-pass design ensure maximum heat transfer, resulting in high steam output per unit of fuel. | High efficiency biomass boiler, Three-pass steam boiler |

| Robust & IBR Certified | Built with durable carbon steel materials and often IBR approved (depending on pressure/capacity) for safety and long operational life. | IBR wood fired boiler, Industrial solid fuel boiler |

| Water Wall / Water Tube Design | Features like water-cooled walls or water tube sections (depending on model) ensure larger heating surfaces and rapid, safe steam generation. | Water wall furnace, Water tube boiler |

| Cost Savings | Utilizes low-cost, renewable biomass fuels, significantly reducing expenditure compared to high-priced oil or gas. | Cost-effective steam generation, Fuel cost reduction |

Ideal for Key Industries

The reliability and cost-efficiency of solid fuel boilers make them indispensable in:

- Textiles: Sizing, dyeing, and drying processes.

- Food Processing: Cooking, sterilization, and preparation.

- Pharmaceuticals & Chemicals: Process heating and reaction chambers.

- Paper & Plywood: Heating and drying applications.

Operating Range

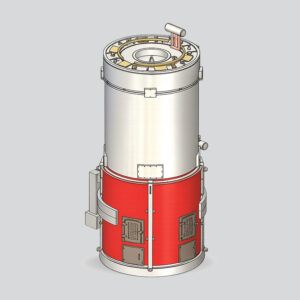

- Capacity – 0.5 TPH to 6.0 TPH

- Fuel- Wood Log, Biomass Briquette

- Pressure- 10.54 Kg/cm² to 21 Kg/cm²

Technical Specifications

| Specification | Unit | SM-05 | SM-7.5 | SM-10 | SM-15 | SM-20 | SM-25 | SM-30 | SM-40 | SM-50 | SM-60 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| General | |||||||||||

| Steam Output From & at 100°C | Kg/hr | 500 | 750 | 1000 | 1500 | 2000 | 2500 | 3000 | 4000 | 5000 | 6000 |

| Working Pressure | Kg/CM² | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 |

| Steam Temperature | °C | 183 | 183 | 183 | 183 | 183 | 183 | 183 | 183 | 183 | 183 |

| No’s of Passes | No’s | Three | Three | Three | Three | Three | Three | Three | Three | Three | Three |

| No’s of Furnace | No’s | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 2 | 2 | 2 |

| Grate Area | M² | 0.85 | 0.95 | 1.25 | 1.7 | 2.2 | 2.5 | 2.9 | 4.15 | 5.7 | 6 |

| Steam Outlet | MM | 40 | 50 | 50 | 80 | 80 | 80 | 100 | 100 | 125 | 150 |

| Heat Transfer Area | M² | 20 | 30 | 40 | 60 | 80 | 100 | 120 | 160 | 200 | 240 |

| Type of Fuel: Wood log, briquette, lignite, coal | |||||||||||

| Boiler Efficiency | |||||||||||

| On woodlog | % | 70 +/-2 | 70 +/-2 | 70 +/-2 | 70 +/-2 | 70 +/-2 | 70 +/-2 | 70 +/-2 | 70 +/-2 | 70 +/-2 | 70 +/-2 |

| On Coal | % | 76 +/-2 | 76 +/-2 | 76 +/-2 | 76 +/-2 | 76 +/-2 | 76 +/-2 | 76 +/-2 | 76 +/-2 | 76 +/-2 | 76 +/-2 |

| Fuel Consumption | |||||||||||

| WoodLog (3500) | Kg/hr | 110 | 165 | 220 | 331 | 441 | 551 | 661 | 882 | 1102 | 1322 |

| Briquette (4000) | Kg/hr | 96 | 145 | 193 | 289 | 386 | 482 | 579 | 771 | 964 | 1157 |

| Lignite (3000) | Kg/hr | 118 | 178 | 237 | 355 | 474 | 592 | 711 | 947 | 1184 | 1421 |

| Coal (4500) | Kg/hr | 79 | 118 | 158 | 237 | 316 | 395 | 474 | 632 | 789 | 947 |

| Electrical Load | |||||||||||

| Feed Water Pump | H.P. | 2.00 | 2.00 | 2.00 | 3.00 | 3.00 | 4.00 | 4.00 | 4.00 | 6.00 | 7.50 |

| I.D fan without BF | H.P. | 3.00 | 5.00 | 5.00 | 7.50 | 10.00 | 12.50 | 15.00 | 20.00 | 25.00 | 30.00 |

| F.D. Fan | H.P. | 1.00 | 1.00 | 2.00 | 3.00 | 5.00 | 5.00 | 7.50 | 7.40 | 10.00 | 12.50 |

| Total Electric Load | H.P. | 6.00 | 8.00 | 9.00 | 13.50 | 18.00 | 21.50 | 26.50 | 31.40 | 41.00 | 50.00 |

| NOTE: In view of constant endeavors to improve our products, we reserve the right to alter or change above specifications without prior notice. | |||||||||||

Frequently Asked Questions

What are biomass briquettes?

Briquettes are "bio-coal" made by compressing agricultural waste (rice husk, groundnut shells, sawdust) into dense logs. they offer a higher calorific value and more uniform burning than loose wood.

Can this boiler run on other fuels like coal or rice husk?

Yes. Our STEAMAX boilers feature a multi-fuel furnace, allowing you to switch between wood, briquettes, coal, or even agro-waste depending on seasonal availability and price.

Why choose wood/briquettes over oil or gas?

The primary driver is cost reduction. Wood and briquettes are significantly cheaper than fossil fuels in India. Additionally, biomass is carbon-neutral, helping industries meet "Green Energy" targets.

How do I store wood and briquettes for the boiler?

Briquettes must be stored in a dry, covered area to prevent moisture absorption, which can reduce efficiency. Wood logs should be seasoned (dried) to ensure maximum heat output.

What is the design of the STEAMAX series?

It is typically a Three-Pass or Four-Pass horizontal package boiler. It often utilizes a "Hybrid" design (Smoke Tube + Water Wall) to provide a large heating surface for rapid steam generation.

What is the efficiency of a wood/briquette fired boiler?

Our standard models achieve 78% to 82% efficiency. With the addition of an Economizer or Air Pre-heater (APH), this can be increased by another 3–5%.

Does it require an external furnace?

For larger wood logs or high-moisture fuels, we provide an external Step Grate or Water-Cooled Furnace to ensure complete combustion and prevent "unburnt" fuel waste.

What steam capacities are available?

The STEAMAX range typically covers 500 kg/hr to 10,000 kg/hr (10 TPH). For very small requirements, we offer vertical "SIB" (Small Industrial Boiler) models.

How does the boiler handle load fluctuations?

The large water volume and robust furnace design allow the boiler to respond quickly to sudden spikes in steam demand, making it ideal for textile dyeing or food processing.

Is ash removal difficult?

No. Our boilers are designed with easily accessible ash pits. For units using high-ash fuels like certain briquettes, we can integrate Automatic Ash Handling systems.

How often should the smoke tubes be cleaned?

Solid fuels produce soot. We recommend cleaning the smoke tubes weekly using a wire brush (soot blowing) to maintain high heat transfer efficiency.

What pollution control equipment is needed?

To comply with CPCB norms, we equip these boilers with Cyclonic Dust Collectors or Multi-cyclones to trap fly ash before the flue gas exits the chimney.

Are these boilers IBR certified?

Yes. We manufacture both IBR and Non-IBR versions. IBR-certified boilers are mandatory for higher pressures and larger capacities in India.

What safety mountings are included?

Standard safety features include:

- Fusible Plugs: To protect against low water levels.

- Dual Safety Valves: To release excess pressure.

- Mobrey Controllers: For automatic water level management.

What is the price of a Wood / Briquette Fired Steam Boiler?

Pricing is based on capacity and automation level. In 2025, estimated costs are:

- 0.5 TPH to 1 TPH: ₹15,00,000.

- 2 TPH to 4 TPH: ₹15,00,000 – ₹28,00,000.

- 5 TPH to 10 TPH: ₹35,00,000 – ₹65,00,000.

- Note: Prices exclude GST, Chimney, and Pollution Control equipment.

How does the initial cost compare to oil-fired boilers?

The initial capital investment for a wood/briquette boiler is slightly higher because of the larger furnace and fuel handling area. However, the running cost is 50% lower.

What is the typical ROI period?

Due to the massive savings in fuel costs (Briquettes at ~₹7-9/kg vs Diesel at ~₹90/L), most factories recover the cost of the boiler within 10 to 18 months.

Are there government subsidies for these boilers?

Yes, several MSME schemes and state government incentives for "Biomass-based Green Energy" provide subsidies ranging from 15% to 25% on the capital cost.

How can I get a custom quote from indianboilers.com?

Visit our Contact Us page or click the WhatsApp icon. Please provide your Steam Output (kg/hr) and the type of fuel available in your area for a formal proposal.

Snehal Bhavsar –

Robust engineering and consistent steam output “Been using the 3-pass wood-fired boiler for six months now. What stands out is the thermal efficiency—it hits the required pressure quickly and maintains a very consistent steam dryness fraction. The design makes maintenance and ash removal much easier than other models we’ve used. Excellent support from the Indian Boilers team during the installation phase as well.”