COMCUBE – Biomass Steam Boiler: Sustainable Energy for Industrial Excellence

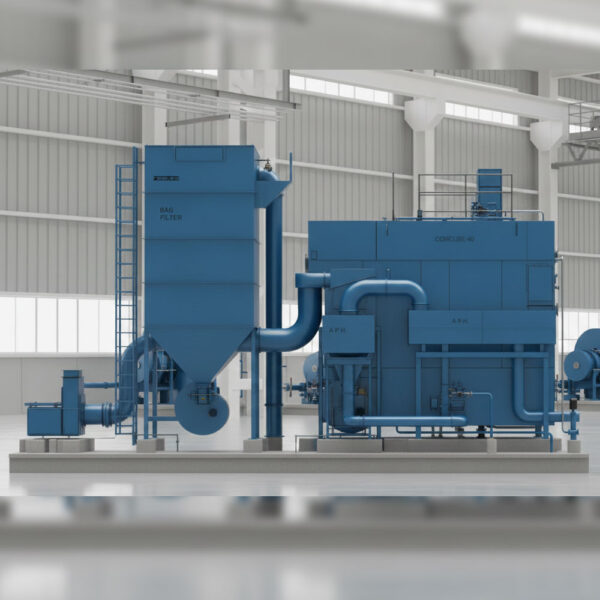

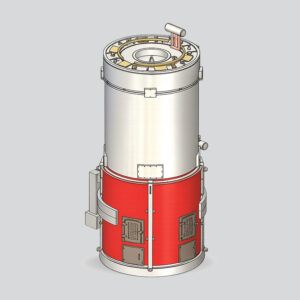

Combcube is packaged, multi-fuel fired steam boiler. The two major options for a solid fuel fired steam boiler were the Integrated Furnace Boiler and the conventional Hybrid Boiler. This meant that the choice boiled down to the reduced site work and better response to load of the Integrated Furnace Boiler, versus the promise of higher efficiency and fuel flexibility of the conventional Hybrid boiler so the ideal solution is the best of both of these designs packed into one which is Combcube. This robust product is a highly compact, efficient, plug and play packaged boiler.

IndianBoilers.com offers a robust range of Biomass Steam Boilers that represent a critical shift toward sustainable and cost-effective energy generation. Designed to efficiently utilize renewable organic materials, these boilers provide the reliable, high-pressure steam essential for industrial processes while drastically reducing your carbon footprint.

Invest in a biomass-fired boiler to achieve energy independence and meet stringent environmental compliance standards.

Key Features & Technology

Our industrial biomass boilers are engineered with advanced combustion technologies to handle a wide variety of fuels common in India, ensuring high thermal efficiency and operational flexibility.

| Feature | Industrial Benefit |

| Multi-Fuel Flexibility | Designed to fire a wide variety of biomass fuels including rice husk, bagasse, wood chips, briquettes, groundnut shell, and wood log, optimizing fuel costs based on local availability. |

| High Thermal Efficiency | Modern designs (such as Fluidized Bed Combustion (FBC) or Water Cooled Grates) achieve thermal efficiencies typically ranging from 85% to 92%, maximizing energy conversion from fuel. |

| Environmental Compliance | Utilizes a carbon-neutral fuel source, significantly reducing reliance on fossil fuels and lowering net greenhouse gas emissions. Often equipped with advanced flue gas treatment systems (e.g., dust collectors) to meet pollution norms. |

| Robust & Reliable Design | Available in configurations like Water Tube or high-capacity Fire Tube designs, built with IBR-grade materials for high-pressure operation and long service life. |

| Automated Operation | Features automatic fuel feeding (stoker, chain grate, etc.) and ash removal systems, ensuring stable combustion, minimal human intervention, and continuous operation. |

Sustainable Cost Savings and Compliance

Switching to a Biomass Steam Boiler is a smart financial and ecological decision for your company:

- Lower Fuel Costs: Biomass fuels are often cheaper and their prices are less volatile than fossil fuels (coal, oil, gas), providing a stable, long-term operational cost advantage.

- Waste Utilization: Converts agricultural or industrial waste materials into valuable steam energy, solving disposal challenges and generating revenue.

- Future-Proof Investment: Positions your business ahead of evolving carbon taxes and increasingly strict emission regulations, ensuring long-term operational license.

Operating Range

- Capacity – 0.5 THP to 6 THP

- Fuel- wood log, Briquette, Lignite and Coal

- Pressure- 10.54 Kg/cm² to 21 Kg/cm²

Technical Specifications

| Specification | Unit | CC-05 | CC-10 | CC-20 | CC-30 | CC-40 | CC-50 | CC-60 | ||

|---|---|---|---|---|---|---|---|---|---|---|

| General | ||||||||||

| Steam Output From & at 100°C | Kg/hr | 500 | 1000 | 2000 | 3000 | 4000 | 5000 | 6000 | ||

| Working Pressure | Kg/CM² | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 | ||

| Steam Temperature | °C | 183 | 183 | 183 | 183 | 183 | 183 | 183 | ||

| No’s of Passes | No’s | Three | Three | Three | Three | Three | Three | Three | ||

| No’s of Furnace | No’s | 1 | 1 | 1 | 1 | 1 | 1 | 1 | ||

| Grate Area | M² | 0.85 | 1.25 | 2.2 | 2.9 | 4.15 | 5.7 | 6 | ||

| Steam Outlet | MM | 40 | 50 | 80 | 100 | 100 | 125 | 150 | ||

| Heat Transfer Area | M² | 20 | 40 | 80 | 120 | 160 | 200 | 240 | ||

| Type of Fuel: woodlog, Briquette, Lignite and Coal | ||||||||||

| Boilers Efficiency with APH | ||||||||||

| On woodlog | % | 78 +/-2 | 78 +/-2 | 78 +/-2 | 78 +/-2 | 78 +/-2 | 78 +/-2 | 78 +/-2 | ||

| On Coal | % | 78 +/-2 | 78 +/-2 | 78 +/-2 | 78 +/-2 | 78 +/-2 | 78 +/-2 | 78 +/-2 | ||

| Fuel Consumption | ||||||||||

| WoodLog (3500) | Kg/hr | 99 | 198 | 396 | 593 | 791 | 989 | 1187 | ||

| Briquette (4000) | Kg/hr | 87 | 173 | 346 | 519 | 692 | 865 | 1038 | ||

| Lignite (3000) | Kg/hr | 115 | 231 | 462 | 692 | 923 | 1154 | 1385 | ||

| Coal (4500) | Kg/hr | 77 | 154 | 308 | 462 | 615 | 769 | 923 | ||

| Electrical Load | ||||||||||

| Feed Water Pump | H.P. | 2.00 | 2.00 | 3.00 | 4.00 | 4.00 | 6.00 | 7.50 | ||

| I.D. fan without BF | H.P. | 3.00 | 5.00 | 10.00 | 15.00 | 20.00 | 25.00 | 30.00 | ||

| F.D. Fan | H.P. | 1.00 | 2.00 | 5.00 | 7.50 | 7.40 | 10.00 | 12.50 | ||

| Total Electric Load | H.P. | 6.00 | 9.00 | 18.00 | 26.50 | 31.40 | 41.00 | 50.00 | ||

| NOTE: In view of constant endeavors to improve our products, we reserve the right to alter or change above specifications without prior notice. | ||||||||||

Frequently Asked Questions

What fuels are compatible with your biomass boilers?

Our boilers are designed for extreme fuel flexibility. Compatible fuels include:

- Agro-residues: Rice husk, mustard stalks, bagasse, and groundnut shells.

- Processed Bio-fuel: Biomass briquettes and pellets.

- Wood Waste: Wood chips, sawdust, and wood logs.

Why is biomass considered a "green" fuel?

Biomass is carbon neutral because the CO2 released during combustion is roughly equal to the amount absorbed by the plants during their growth, creating a closed carbon cycle.

How does switching to biomass help with environmental compliance?

Using biomass significantly reduces sulfur and greenhouse gas emissions. At indianboilers.com, we equip our systems with advanced pollution control technology (like Bag Filters and Cyclonic Dust Collectors) to meet stringent CPCB norms.

What is the difference between your HUSKPOWER and COMCUBE series?

- HUSKPOWER: Optimized specifically for rice husk using Fluidized Bed Combustion (FBC) for high-ash efficiency.

- COMCUBE: A compact, multi-fuel "plug-and-play" boiler ideal for smaller capacities and diverse biomass types.

What combustion technologies do you use?

We offer various technologies based on your fuel:

- Fluidized Bed Combustion (FBC): For fuels like rice husk and coal.

- Fixed Grate / External Furnace: For wood logs and briquettes.

- Bubbling Bed: For high-moisture biomass.

What is the efficiency of an Indian Boilers biomass system?

Our modern designs, incorporating heat recovery units like Economizers and Air Pre-heaters (APH), consistently achieve thermal efficiencies between 78% and 85%.

What steam capacities are available?

We manufacture biomass boilers ranging from 0.5 TPH (500 kg/hr) for small units up to 20 TPH for large-scale industrial plants.

Can your biomass boilers handle high pressure?

Yes. Our standard models are designed for 10.54 kg/cm², but we custom-engineer high-pressure units up to 21 kg/cm² for specialized applications or power generation.

Do you offer automatic fuel feeding?

Yes. Our systems can be equipped with Screw Feeders or Rotary Feeders to automate fuel delivery, ensuring stable combustion and reducing manual labor.

How is ash managed in these boilers?

Our boilers are designed with accessible ash pits for manual removal. For larger installations, we offer Automatic Ash Handling Systems that continuously remove ash without interrupting the boiler’s operation.

Is water treatment necessary for biomass boilers?

Yes. To prevent scale formation and tube corrosion, a Water Softener Plant is required. This ensures the longevity of the boiler and maintains peak heat transfer rates.

Are these boilers IBR certified?

We provide both IBR (Indian Boiler Regulations) and Non-IBR boilers. For high-pressure industrial applications, IBR certification is recommended for safety and legal compliance.

What safety features are included?

Standard safety mountings include Dual Safety Valves, Mobrey water level controllers, Fusible Plugs, and Low-water alarms to ensure fail-safe operation.

Can I use biomass boilers for space heating?

While primarily used for industrial steam, our VTFH-Series hot water boilers are perfect for large-scale space heating in hotels, hospitals, and commercial complexes.

What is the price of an Industrial Biomass Boiler?

The price varies based on capacity (TPH), fuel type, and automation. On indianboilers.com, our standard industrial units typically range:

- Small (500 kg/hr to 1 TPH): Starting from ₹2,000,000 to ₹10,00,000.

- Medium (2 TPH to 5 TPH): Between ₹15,00,000 and ₹35,00,000.

- Large (10 TPH+): Specialized systems can exceed ₹60,00,000 depending on the degree of automation and pollution control equipment.

What factors influence the final cost?

The price is determined by the TPH capacity, the Working Pressure, the choice between IBR vs Non-IBR, and whether you opt for Automatic Fuel & Ash Handling.

How much can I save on fuel costs?

Switching from Diesel (HSD) or Furnace Oil to Biomass can reduce your fuel bill by 40% to 60%. Biomass is generally the most cost-effective fuel available in the Indian market today.

What is the typical Return on Investment (ROI)?

Due to the massive savings in fuel costs, most of our industrial clients recover their initial capital investment within 12 to 24 months.

How can I get a custom quote for my plant?

Visit indianboilers.com and use our "Contact Us" form or WhatsApp link. Providing your required steam output (TPH) and available fuel type will allow our engineers to provide a precise technical and commercial proposal.

Reviews

There are no reviews yet.