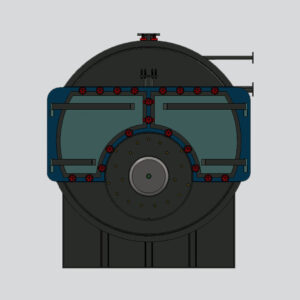

High Pressure Industrial Steam Boiler 750 Kg/hr

Rugged Engineering | Rapid Pressurization | Peak Industrial Performance

At IndianBoilers.com, our 750 Kg/hr High-Pressure Series is engineered for demanding industrial processes that require a consistent, high-volume steam supply. Designed to withstand rigorous duty cycles, this boiler combines the thermal inertia of a shell-type design with the efficiency of modern combustion technology.

Manufactured in our state-of-the-art facility in Ahmedabad, these units are the preferred choice for factories where steam quality and pressure stability are critical to production uptime.

Key Features & Performance

- Exceptional Steam Quality: Designed with a large steam disengagement space to ensure high-dryness fraction steam, preventing water carryover to your machines.

- High-Pressure Capability: Standard models support up to 10.54 $Kg/cm^2$, with specialized heavy-duty versions engineered for 17.5 $Kg/cm^2$ and above.

- Three-Pass Wet-Back Design: Maximizes heat extraction and eliminates the maintenance-heavy rear refractory, ensuring 88%–90% thermal efficiency.

- Fuel Versatility: Available in configurations for HSD/Diesel, PNG, LPG, or Dual-Fuel burners to suit your local infrastructure.

- Quick Pressure Recovery: Optimized furnace geometry allows the boiler to respond rapidly to sudden surges in steam demand.

- Robust Construction: Built using IBR-grade SA 515 Gr. 70 boiler-quality plates and seamless tubes for a service life exceeding 15+ years.

Core Industry Applications

- Textile Processing: High-pressure steam for high-speed stenters and dyeing units.

- Chemical Plants: Reliable heat for large-scale pressurized reactors and distillation columns.

- Plywood & Laminates: Consistent temperature for heavy-duty hydraulic presses.

- Food & Dairy: Pasteurization and sterilization for large-volume processing lines.

- Pharmaceuticals: Centralized steam for multi-unit sterilization and HVAC humidification.

Safety & Automation

When you invest in an Indian Boilers system, safety is built-in:

- Triple-Safety Interlocks: Includes dual IBR safety valves, high-pressure cut-offs, and low-water level alarms with automatic burner lockout.

- PLC-Based Control Panel: Features a user-friendly HMI for real-time monitoring of steam pressure, stack temperature, and fuel consumption.

- Advanced Feedwater System: Equipped with high-pressure multi-stage centrifugal pumps to ensure reliable water injection even at peak pressures.

Advantages

- IBR Expertise: We handle all IBR documentation and approval processes, providing you with a “ready-to-fire” certified unit.

- Energy Audits: Our engineers can help you integrate Economizers or Air Pre-heaters to reduce your monthly fuel bill by up to 10%.

- Local Support: Based in Ahmedabad, we offer 24/7 service response and a comprehensive inventory of genuine spare parts.

Technical Specifications

| Specification | Unit | SM-05 | SM-7.5 | SM-10 | SM-15 | SM-20 | SM-25 | SM-30 | SM-40 | SM-50 | SM-60 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| General | |||||||||||

| Steam Output From & at 100°C | Kg/hr | 500 | 750 | 1000 | 1500 | 2000 | 2500 | 3000 | 4000 | 5000 | 6000 |

| Working Pressure | Kg/CM² | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 |

| Steam Temperature | °C | 183 | 183 | 183 | 183 | 183 | 183 | 183 | 183 | 183 | 183 |

| No’s of Passes | No’s | Three | Three | Three | Three | Three | Three | Three | Three | Three | Three |

| No’s of Furnace | No’s | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 2 | 2 | 2 |

| Grate Area | M² | 0.85 | 0.95 | 1.25 | 1.7 | 2.2 | 2.5 | 2.9 | 4.15 | 5.7 | 6 |

| Steam Outlet | MM | 40 | 50 | 50 | 80 | 80 | 80 | 100 | 100 | 125 | 150 |

| Heat Transfer Area | M² | 20 | 30 | 40 | 60 | 80 | 100 | 120 | 160 | 200 | 240 |

| Type of Fuel: Wood log, briquette, lignite, coal | |||||||||||

| Boiler Efficiency | |||||||||||

| On woodlog | % | 70 +/-2 | 70 +/-2 | 70 +/-2 | 70 +/-2 | 70 +/-2 | 70 +/-2 | 70 +/-2 | 70 +/-2 | 70 +/-2 | 70 +/-2 |

| On Coal | % | 76 +/-2 | 76 +/-2 | 76 +/-2 | 76 +/-2 | 76 +/-2 | 76 +/-2 | 76 +/-2 | 76 +/-2 | 76 +/-2 | 76 +/-2 |

| Fuel Consumption | |||||||||||

| WoodLog (3500) | Kg/hr | 110 | 165 | 220 | 331 | 441 | 551 | 661 | 882 | 1102 | 1322 |

| Briquette (4000) | Kg/hr | 96 | 145 | 193 | 289 | 386 | 482 | 579 | 771 | 964 | 1157 |

| Lignite (3000) | Kg/hr | 118 | 178 | 237 | 355 | 474 | 592 | 711 | 947 | 1184 | 1421 |

| Coal (4500) | Kg/hr | 79 | 118 | 158 | 237 | 316 | 395 | 474 | 632 | 789 | 947 |

| Electrical Load | |||||||||||

| Feed Water Pump | H.P. | 2.00 | 2.00 | 2.00 | 3.00 | 3.00 | 4.00 | 4.00 | 4.00 | 6.00 | 7.50 |

| I.D fan without BF | H.P. | 3.00 | 5.00 | 5.00 | 7.50 | 10.00 | 12.50 | 15.00 | 20.00 | 25.00 | 30.00 |

| F.D. Fan | H.P. | 1.00 | 1.00 | 2.00 | 3.00 | 5.00 | 5.00 | 7.50 | 7.40 | 10.00 | 12.50 |

| Total Electric Load | H.P. | 6.00 | 8.00 | 9.00 | 13.50 | 18.00 | 21.50 | 26.50 | 31.40 | 41.00 | 50.00 |

| NOTE: In view of constant endeavors to improve our products, we reserve the right to alter or change above specifications without prior notice. | |||||||||||

Frequently Asked Questions

What constitutes "High Pressure" for this specific model?

While standard boilers operate at 7–10 Kg/cm2, our high-pressure series is designed for 10.54 Kg/cm2 to 21 Kg/cm2 to meet specialized industrial needs.

How fast can this boiler reach its maximum operating pressure?

Depending on the design (Shell vs. Coil), it typically reaches full pressure in 15 to 25 minutes from a cold start.

What is the thermal efficiency of the 750 Kg/hr model?

The base efficiency is 88% to 90%, which can be enhanced to 95% with an Indian Boilers' high-efficiency economizer.

Does it produce "Dry" steam?

Yes. It features a large steam disengagement space and internal moisture separators to ensure high-quality, dry saturated steam.

Which fuels are compatible with this 750 Kg boiler?

This unit is a multi-fuel system compatible with Diesel (HSD), LDO, PNG, and LPG.

What is the fuel consumption at full load?

Approximate consumption is 48–52 Liters/hr for Diesel or 52–56 NM3/hr for PNG, depending on feedwater temperature.

Can I install a dual-fuel burner on this model?

Yes. We can equip the unit with a burner that switches between gas and oil, providing flexibility during fuel price fluctuations.

How does the "3-Pass Wet Back" design improve fuel savings?

It ensures that heat stays in the water longer and eliminates the need for a rear refractory, reducing heat loss and maintenance costs.

What is the power consumption for the 750 Kg/hr boiler?

The total connected electrical load (burner + feed pump) is approximately 5 HP to 7.5 HP.

Is this boiler IBR certified?

Yes. Every 750 Kg/hr high-pressure unit is manufactured strictly under IBR (Indian Boiler Regulations) guidelines.

What safety interlocks are provided?

It includes dual IBR safety valves, a low-water level alarm with burner lockout, and a high-steam pressure cut-off switch.

What material is used for the pressure parts?

We use ASTM/SA 515/516 Gr. 70 boiler-quality plates and IBR-certified seamless carbon steel tubes.

How often should IBR inspections be conducted?

As per law, an annual inspection by the local Boiler Inspector is required to renew the operating certificate.

What is the "Hydraulic Test" pressure for this unit?

The boiler is hydraulically tested at 1.5 times its design pressure to ensure structural integrity.

Is this model available as a skid-mounted unit?

Yes. We provide a skid-mounted "Plug-and-Play" package where the boiler, pump, and panel are pre-aligned for fast installation.

What are the water quality requirements?

To prevent scaling at high pressure, feedwater must be treated via a Water Softener to keep hardness below 5 ppm.

What is the footprint (size) of the 750 Kg/hr boiler?

It is a horizontal shell-type unit, typically requiring an area of approximately 10ft x 6ft, excluding the chimney and water tank.

Does it require a tall chimney?

Yes. Depending on local pollution norms, a 30-meter chimney is usually required for proper emission dispersion.

Do you provide maintenance support in Ahmedabad?

Yes, our Ahmedabad-based headquarters offers 24/7 service, genuine spares, and Annual Maintenance Contracts (AMC).

Dhaval Kamdar –

5 stars for the 750 kg/hr series! We’ve seen a noticeable drop in fuel consumption thanks to the three-pass wet-back design. The thermal efficiency is consistently around 88-90%, and the PLC-based control panel makes monitoring the system very straightforward. It’s a robust piece of engineering that has become the backbone of our production line. Great value for the investment.