A Guide to Zero-Carbon Heating

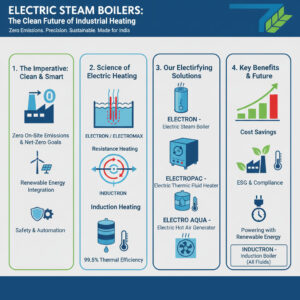

The global push for climate action has placed the industrial sector under unprecedented pressure to decarbonize. For process heating—a historically energy-intensive and emission-heavy operation—the search for a genuinely clean alternative to fossil fuels is paramount. The solution lies not in complex emission control systems for traditional boilers, but in a complete paradigm shift: Electric Boilers.

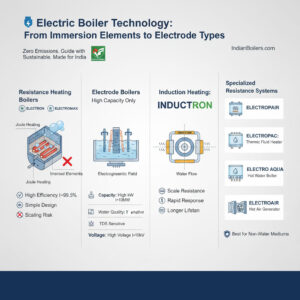

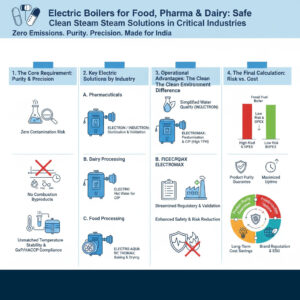

Electric heating technology represents the pinnacle of clean industrial operation. They produce zero on-site emissions, are highly efficient, and integrate seamlessly with renewable energy sources. At IndianBoilers.com, we provide a full spectrum of advanced electric heating solutions designed to meet the most stringent environmental standards: from the precision of the ELECTRON – Electric Steam Boiler and the heavy-duty power of the ELECTROMAX – Electric IBR Steam Boiler, to the specialized heat from the ELECTROPAC – Electric Thermic Fluid Heater, ELECTRO AQUA – Electric Hot Water Boiler, ELECTROAIR – Electric Hot Air Generator, and the innovative INDUCTRON – Induction Boiler.

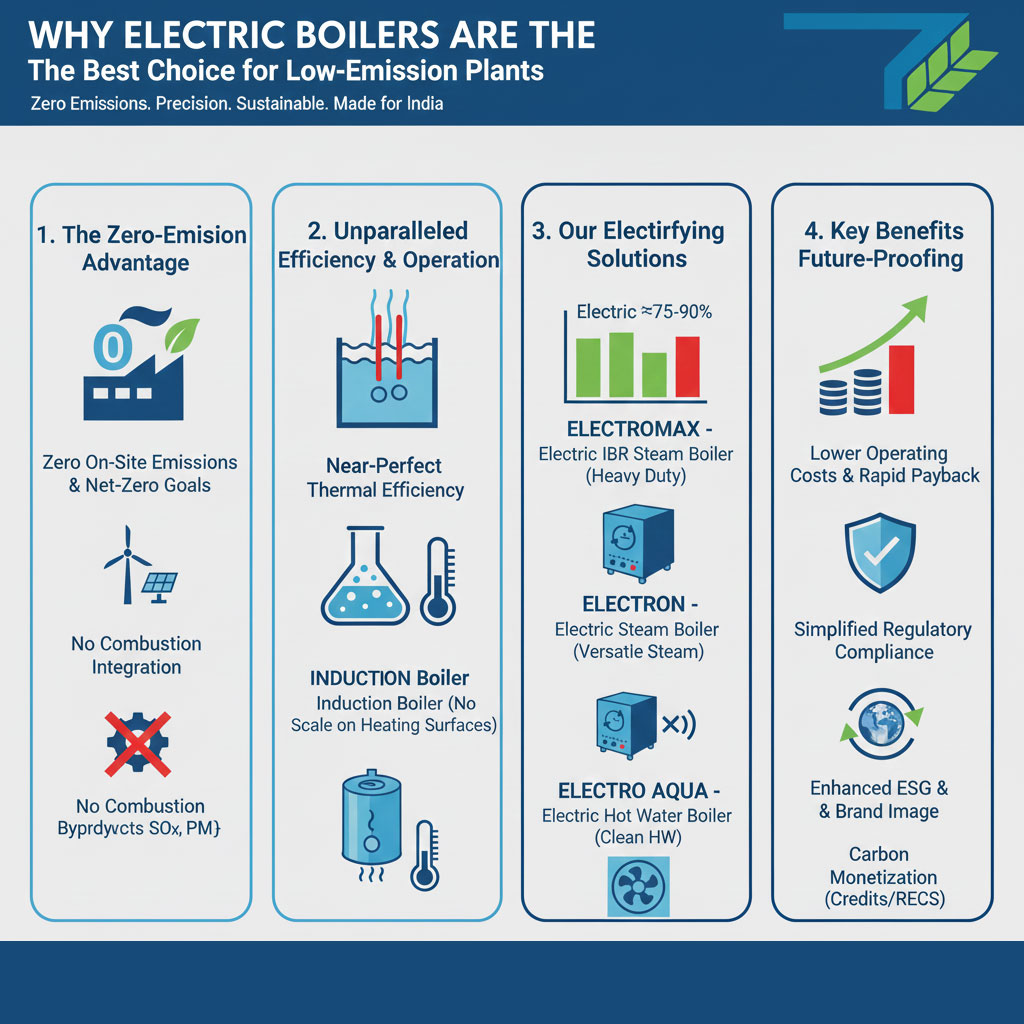

1. The Zero-Emission Advantage: Defining Clean Industrial Heating

To be a “Low-Emission Plant” today means striving for zero direct emissions. Electric boilers inherently offer this capability, fundamentally solving the emissions problem at its source.

A. Eliminating All Combustion Byproducts

Traditional boilers that burn coal, diesel, or natural gas produce several harmful pollutants as byproducts of combustion:

- Carbon Dioxide : The primary greenhouse gas.

- Nitrogen Oxides: Harmful air pollutants contributing to smog and acid rain.

- Sulphur Oxides : Major contributors to acid rain and respiratory problems.

- Particulate Matter: Fine airborne particles that pose significant health risks.

Electric boilers, such as the ELECTRON and ELECTROMAX series, operate purely on electrical resistance or induction. There is no combustion, meaning there are no flues, no stacks, no complex scrubbing systems, and zero direct emissions of these harmful pollutants. This is the single biggest step a plant can take towards achieving an effective net-zero footprint.

B. The Integration with the Green Grid

The environmental impact of an electric boiler shifts entirely to the source of the electricity. As India’s power grid rapidly integrates more renewable energy (solar, wind, hydro), the electricity powering an electric boiler becomes progressively cleaner.

- Decoupling Emissions: By using an electric boiler, a plant separates its heating needs from the volatility and emissions of fossil fuel markets.

- Future-Proofing: An investment in an electric boiler today guarantees that your heating process will get cleaner every year as the national grid decarbonizes, automatically aligning your operations with future climate targets.

2. Unparalleled Efficiency and Operational Excellence

Low-emission operations are not just about being clean; they are about being highly efficient. Electric boilers excel in converting input energy into usable heat.

A. Near-Perfect Thermal Efficiency

Fossil fuel boilers lose significant heat through the stack (exhaust gases), leading to maximum thermal efficiencies typically ranging from 75% to 90%.

Electric boilers, conversely, achieve thermal efficiencies approaching 99.5%. Almost all the electrical energy consumed is directly converted into steam, hot water, or thermal fluid heat.

This superior energy conversion means that despite the higher cost per unit of electricity compared to fossil fuel, the extreme efficiency minimizes waste and reduces overall energy consumption.

B. Precision and Stability

- Precise Control: Electric boilers offer exceptionally fine-tuned temperature and pressure control, critical for sensitive processes in pharmaceuticals, specialty chemicals, and food & beverage. The rapid response of the heating elements in the ELECTRON or ELECTROPAC allows for temperature stability unmatched by combustion systems.

- Quiet Operation and Small Footprint: Without burners, fans, or fuel-handling systems, electric boilers operate quietly and require significantly less physical space. This is a crucial advantage for plants located in urban or densely packed industrial areas.

3. IndianBoilers.com’s Electric Solutions for Every Industrial Need

Our comprehensive electric range is engineered to replace any fossil fuel system with a clean, efficient electric alternative.

A. High-Pressure Steam for Heavy Industry

For continuous, heavy-duty steam applications:

- ELECTROMAX – Electric IBR Steam Boiler: This system is built to comply with the stringent Indian Boiler Regulations (IBR), providing the necessary robustness and safety for large-scale operations. It delivers high-pressure steam without the need for a fuel supply line, storage tank, or chimney, making it the preferred choice for major pharmaceutical and textile factories aiming for deep decarbonization.

- INDUCTRON – Induction Boiler: For plants that prioritize system longevity and minimal scaling on the heating surface, the INDUCTRON offers an advanced, non-contact heating method. It uses electromagnetic fields to heat the medium directly, resulting in minimal heat-up time and exceptionally durable components.

B. Versatile Medium-Pressure Steam and Hot Water

For general utilities, smaller processes, and standby applications:

- ELECTRON – Electric Steam Boiler: Our workhorse for instantaneous, clean steam. Perfect for sterilization in hospitals and food production where steam purity is non-negotiable and demand is typically intermittent or low-to-medium.

- ELECTRO AQUA – Electric Hot Water Boiler: Efficiently generates clean hot water for laundries, domestic use, and low-temperature process heating, immediately eliminating the $\text{CO}_2$ from small fossil fuel water heaters.

C. Specialized Heating Solutions

For processes requiring specific heat transfer mediums:

- ELECTROPAC – Electric Thermic Fluid Heater: Essential for applications requiring very high temperatures (up to 300 C or more) without the associated high pressures of steam. The ELECTROPAC ensures flameless, uniform heating, which is ideal for chemical reactors, paint curing, and certain manufacturing processes.

- ELECTROAIR – Electric Hot Air Generator: Delivers clean, precisely controlled hot air for drying, curing, and space heating, avoiding the introduction of combustion products (like SOx) into sensitive drying processes like food or specialized materials.

4. Addressing the Main Challenge: Electrical Power and Cost

While electric boilers are the cleanest option, the transition requires careful consideration of the energy source.

A. Infrastructure Upgrade and Cost Analysis

The primary barrier to large-scale electric boiler adoption is the requirement for substantial electrical infrastructure (transformers, lines, switchgear) to handle the high kilowatt demand.

- Cost-Benefit Analysis: While the initial capital cost (CAPEX) for infrastructure can be high, it must be balanced against the drastically lower operating expenses (OPEX) from reduced maintenance, near-zero fuel handling costs, and the elimination of ongoing emission compliance fees.

- Off-Peak Operation: Industries with flexible schedules can utilize electric boilers during off-peak hours when electricity is cheaper, storing the thermal energy for use during peak hours. This is a powerful strategy to reduce the effective operational cost.

B. The Maintenance Advantage

The simplicity of electric heating translates directly into lower maintenance overhead.

- No Fire-Side Maintenance: No soot blowing, no burner cleaning, and no refractory maintenance required.

- Reduced Water-Side Issues (INDUCTRON): The non-contact heating core of the INDUCTRON resists scale buildup on the heating surface better than traditional resistance elements, extending service intervals and maintaining high efficiency over time.

5. The Low-Emission Future is Electric

For any plant aiming to genuinely become low-emission, the path forward leads to electrification. Every unit of energy currently derived from burning fuel is a unit of pollution eliminated by switching to systems like the ELECTROMAX or ELECTROPAC.

This is more than an equipment purchase; it’s a strategic corporate commitment to sustainability, offering compelling benefits:

- Immediate Environmental Compliance: Meet and exceed environmental standards immediately.

- Enhanced Brand Image: Boost your company’s ESG score and appeal to environmentally conscious consumers and investors.

- Simplified Operations: Eliminate the complexity and hazard of fossil fuel handling.

- Guaranteed Future-Proofing: Your process heating gets cleaner as the grid gets greener.

The time for incremental change is over. The clean future of industrial heating is here, powered by the reliable, zero-emission technology from IndianBoilers.com.

Is your plant ready to become a zero on-site emission leader?

Contact IndianBoilers.com today for a detailed electrical load assessment and a quote on our ELECTRON, ELECTROMAX, ELECTROPAC, ELECTRO AQUA, ELECTROAIR, or INDUCTRON electric heating solutions.