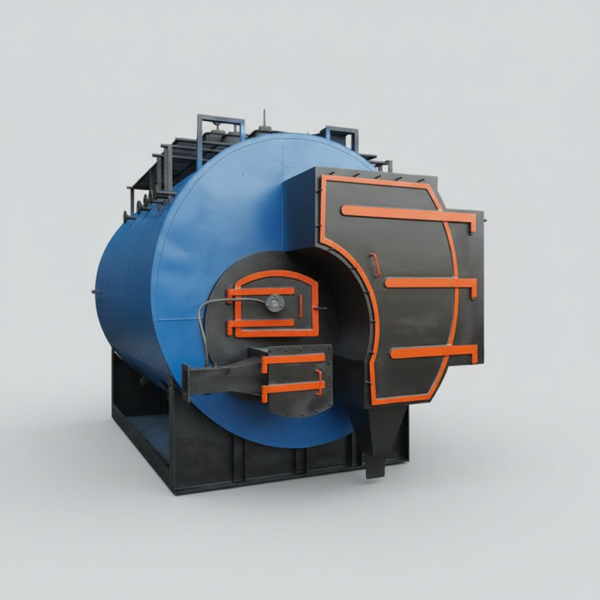

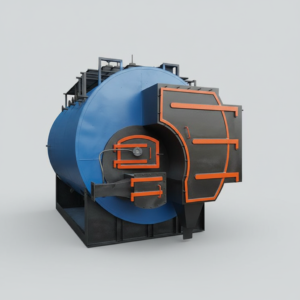

Power Your Plant with Renewable Energy: Introducing HUSKPOWER Rice Husk Fired Steam Boiler

IndianBoilers.com – HUSKPOWER, the next-generation Rice Husk Fired Steam Boiler. Designed for industries seeking to leverage low-cost, sustainable biomass fuel, HUSKPOWER delivers high efficiency and reliable steam while minimizing operating expenses.

Switch to Rice Husk—an abundant and cost-effective agricultural waste—and achieve up to 74% fuel efficiency with our specialized combustion technology.

Huskpower, the next generation rice husk fired boilers from Indianboilers.com, are designed to provide low-cost heating with fuel efficiency as high as 74 %. Bubbling bed combustion, gives higher residence time to facilitate complete combustion, thus improving efficiency.

Key Features & Engineered Advantages (HUSKPOWER)

The HUSKPOWER series is specifically engineered to handle the unique challenges of rice husk combustion, ensuring durability and peak performance:

| Feature | Benefit for Your Operations | |

| Bubbling Bed Combustion | Gives fuel a higher residence time, facilitating complete combustion to enhance output and achieve efficiency as high as 76% (with APH). | rice husk fired boiler, biomass steam boiler, bubbling bed combustion |

| Low-Cost Heating Solution | Utilizes economical rice husk as fuel, drastically reducing recurring fuel costs compared to fossil fuels. | low cost industrial boiler, rice husk fuel efficiency |

| Special Ash Management | Features special ferrules to protect smoke tubes from abrasive husk ash, minimizing wear and extending boiler life. | boiler for abrasive fuel, ash management system |

| Innovative Top Loading Design | Prevents common issues like nozzle failure and the bulging of the reversal chamber, ensuring continuous, reliable operation. | durable biomass boiler, boiler design for rice husk |

| IBR Compliance | Built to meet high-pressure regulatory standards for robust, safe industrial applications (IBR compliance assumed based on high capacity and pressure range). | IBR biomass boiler, high pressure steam generator |

Operating Range

- Capacity – 1.0 TPH to 6.0 TPH

- Fuel- Rice Husk

- Pressure- 10.54 Kg/cm² to 21 Kg/cm²

Technical Specifications

| Specification | Unit | HP-10 | HP-20 | HP-30 | HP-40 | HP-50 | HP-60 | |||

|---|---|---|---|---|---|---|---|---|---|---|

| General | ||||||||||

| Steam Output From & at 100°C | Kg/hr | 1000 | 2000 | 3000 | 4000 | 5000 | 6000 | |||

| Working Pressure | Kg/CM² | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 | |||

| Steam Temperature | °C | 183 | 183 | 183 | 183 | 183 | 183 | |||

| No’s Passes | No’s | Three | Three | Three | Three | Three | Three | |||

| No’s of Furnace | No’s | 1 | 1 | 1 | 1 | 1 | 1 | |||

| Steam Outlet | MM | 50 | 80 | 100 | 100 | 125 | 150 | |||

| HTA | M² | 40 | 80 | 120 | 160 | 200 | 240 | |||

| Type of Crushed Fuel: Rice Husk | ||||||||||

| Boiler Efficiency with APH | ||||||||||

| On Rice Husk | % | 76 +/-2 | 76 +/-2 | 76 +/-2 | 76 +/-2 | 76 +/-2 | 76 +/-2 | |||

| Fuel Consumption | ||||||||||

| Rice Husk (3000) | Kg/hr | 231 | 462 | 692 | 923 | 1154 | 1385 | |||

| Electrical Load | ||||||||||

| Feed Water Pump | H.P. | 2.00 | 3.00 | 4.00 | 4.00 | 6.00 | 7.50 | |||

| I.D. fan without BF(Optional) | H.P. | 5.00 | 10.00 | 15.00 | 20.00 | 25.00 | 30.00 | |||

| F.D. Fan | H.P. | 3.00 | 5.00 | 7.50 | 10.00 | 15.00 | 20.00 | |||

| F.T. fan | H.P. | 3.00 | 5.00 | 7.50 | 10.00 | 15.00 | 20.00 | |||

| Screw feeder with VFD | H.P. | 1.00 | 2.00 | 2.00 | 3.00 | 2.00 | 6.00 | |||

| Total Electric Load | H.P. | 10.00 | 18.00 | 34.00 | 44.00 | 61.00 | 77.50 | |||

| NOTE: In view of constant endeavors to improve our products, we reserve the right to alter or change above specifications without prior notice. | ||||||||||

Frequently Asked Questions

Why is rice husk a popular fuel in India?

India is one of the world's largest rice producers. Rice husk is abundant, carbon-neutral, and often available at a fraction of the cost of coal or oil. For rice millers, it is a "zero-cost" fuel that turns waste into energy.

Is rice husk better than wood or coal?

While rice husk has a lower calorific value (3,000 kcal/kg) than coal, it is significantly cheaper. It burns cleanly and is more sustainable, though it requires specialized furnace designs to manage its high silica ash.

Is this boiler carbon neutral?

Yes. The CO2 released during the combustion of rice husk is equal to the amount absorbed by the rice plant during its growth, making it an environmentally responsible choice.

What is "Bubbling Bed Combustion"?

In our HUSKPOWER boilers, we use bubbling bed technology. This keeps the fuel particles in a fluid-like state, increasing "residence time" to ensure complete combustion of every husk particle, achieving efficiencies up to 76%.

How do you handle the abrasive nature of husk ash?

Rice husk ash contains over 90% silica, which is highly abrasive. We use specialized stainless steel ferrules at the tube inlets to protect them from erosion, significantly extending the life of the boiler tubes.

What is the "Top Feeding" system?

Unlike traditional manual feeding, our top-feed system uses high-velocity fans to spray husk into the furnace. This ensures even distribution, prevents "clumping," and allows for automated operation.

What is the typical steam capacity of these boilers?

We manufacture the HUSKPOWER series in capacities ranging from 1 TPH to 6 TPH. For larger requirements (up to 20 TPH), we offer specialized Fluidized Bed Combustion (FBC) systems.

Can it run on other fuels if husk is unavailable?

Yes. While optimized for husk, the furnace can be adapted to burn other agro-waste like sawdust, crushed peanut shells, or small wood chips.

What is the fuel consumption rate?

On average, a 1 TPH boiler consumes approximately 230–250 kg of rice husk per hour to produce 1,000 kg of steam, depending on the husk's moisture content.

How do you manage the large volume of ash?

Rice husk produces about 20% ash. Our boilers feature large, easy-access ash pits and can be fitted with Multi-cyclone Dust Collectors to ensure clean emissions and easy ash disposal.

Does it require an Air Pre-Heater (APH)?

To achieve maximum efficiency (above 74%), we highly recommend an APH. It uses waste heat from flue gases to heat the combustion air, speeding up the ignition of the husk.

What industries benefit most from this boiler?

- Rice Mills: For parboiling and drying paddy.

- Textile Mills: For dyeing and processing.

- Solvent Extraction Plants: For oil recovery processes.

- Distilleries: For fermentation and distillation heating.

Is the boiler IBR certified?

Absolutely. All industrial units from indianboilers.com are manufactured under Indian Boiler Regulations (IBR), ensuring they meet the highest safety and material standards.

How often should the boiler be cleaned?

Because of the high ash content, the furnace should be de-ashed daily. The smoke tubes should be cleaned weekly to prevent soot buildup, which can lower efficiency.

What safety controls are included?

Standard features include Low Water Cut-offs, Dual Safety Valves, and VFD-controlled fuel feeders to prevent over-pressurization or fuel-clogging.

What is the price of a Rice Husk Fired Steam Boiler?

Prices vary based on capacity and automation. For 2025, the approximate rates are:

- 1 TPH to 2 TPH: ₹1,500,000.

- 3 TPH to 6 TPH: ₹15,00,000 – ₹35,00,000.

- Large FBC Units (10 TPH+): Upwards of ₹60,00,000.

What factors impact the final cost?

The price depends on Steam Capacity (TPH), Working Pressure, the inclusion of Pollution Control Equipment (like Bag Filters), and the level of Feeding Automation.

What is the typical ROI (Return on Investment)?

For a rice mill using its own husk, the ROI is incredibly fast—often between 6 to 12 months. For other industries buying husk, the savings over Diesel or Coal typically result in an ROI within 18 months.

How can I get a quote from indianboilers.com?

Visit our website at indianboilers.com and fill out the inquiry form, or contact us via WhatsApp with your required TPH and working pressure for a customized technical-commercial offer.

Rahul Deshpande –

We recently installed the Rice Husk Fired Steam Boiler from IndianBoilers.com and are extremely impressed with its performance and build quality. This boiler has significantly reduced our fuel costs by utilizing rice husk — an abundant and low-cost biomass fuel — which has made a noticeable difference in our operational expenses. The advanced bubbling bed combustion technology ensures excellent fuel efficiency and consistent steam output, even under heavy loads.