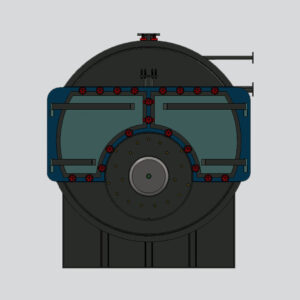

Gas-Fired Industrial Steam Boiler 200 Kg/hr

High Efficiency | Instant Steam | Zero Soot Technology

The VEPOMAX 200 Kg/hr gas-fired boiler is the gold standard for small-to-medium industrial applications. Whether running on PNG (Piped Natural Gas) or LPG, this unit offers a clean, automated, and highly cost-effective alternative to traditional oil-fired systems.

Manufactured in Ahmedabad, our VEPOMAX series features a compact vertical design that delivers high-quality dry steam within minutes, making it ideal for industries where space and startup time are critical factors.

Key Features & Performance

- Rapid Steam Generation: Reaches full working pressure in just 4–6 minutes from a cold start.

- 88% Thermal Efficiency: Optimized 3-pass heat exchanger ensures maximum fuel-to-steam conversion.

- Fully Automatic Control: Features a “single-switch” start with automatic pressure modulation and water level control via a PLC panel.

- Clean Combustion: No soot, no smoke, and no ash handling. The gas burner ensures a blue flame for 100% clean operation.

- Compact Footprint: The vertical design saves up to 40% more floor space compared to horizontal models.

- Sophisticated Gas Train: Includes high-quality gas filters, pressure regulators, and dual-block safety valves for total operational security.

Core Industry Applications

The VEPOMAX 200 Kg/hr is highly recommended for:

- Laundry & Dry Cleaning: Steady, high-pressure dry steam for presses and washers.

- Food Processing: Ideal for small dairies, bakeries, and beverage pasteurization.

- Chemical & Pharma: Precision heating for small-scale reactors and laboratory use.

- Hospitality: Centralized hot water and steam sterilization for boutique hotels and hospitals.

Advantages

- Plug-and-Play Installation: Delivered as a pre-piped and pre-wired skid unit. Just connect gas, water, and power.

- Advanced Gas Train: Includes a multi-block safety valve, gas filter, and pressure regulators for 100% operational safety.

- Environmentally Friendly: Meets all current pollution control board norms for stack emissions.

Technical Specifications

| Specification | Unit | VX-02 | VX-03 | VX-04 | VX-05 | VX-06 | VX-08 | VX-10 |

|---|---|---|---|---|---|---|---|---|

| General | ||||||||

| Steam Output From & at 100°C | Kg/hr | 200 | 300 | 400 | 500 | 600 | 800 | 1000 |

| Working Pressure | Kg/CM² | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 |

| Steam Temperature | °C | 183 | 183 | 183 | 183 | 183 | 183 | 183 |

| Efficiency (On Oil) | % | 88% +/-2 | 88% +/-2 | 88% +/-2 | 88% +/-2 | 88% +/-2 | 88% +/-2 | 88% +/-2 |

| Efficiency (On Gas) | % | 87% +/-2 | 87% +/-2 | 87% +/-2 | 87% +/-2 | 87% +/-2 | 87% +/-2 | 87% +/-2 |

| Type of Fuel: HSD, LPG, NG, FO, LDO | ||||||||

| Fuel of Firing: Pressure Jet – Reverse Fuel Dual Block | ||||||||

| Fuel Consumption | ||||||||

| Diesel (10500) | Kg/hr | 12 | 18 | 23 | 29 | 35 | 47 | 58 |

| Furnace Oil (9600) | Kg/hr | 13 | 19 | 26 | 32 | 38 | 51 | 64 |

| LDO (10200) | Kg/hr | 12 | 18 | 24 | 30 | 36 | 48 | 60 |

| LPG (11000) | Kg/hr | 11 | 17 | 23 | 28 | 34 | 45 | 56 |

| Natural Gas (8900) | M³/hr | 14 | 21 | 28 | 35 | 42 | 56 | 70 |

| Electrical Load | ||||||||

| Feed Pump | H.P. | 1.00 | 1.00 | 1.00 | 2.00 | 2.00 | 3.00 | 3.00 |

| FD Fan | H.P. | 1.00 | 1.00 | 2.00 | 2.00 | 3.00 | 3.00 | 5.00 |

| Fuel Pump (Oil) | H.P. | 0.50 | 0.50 | 0.50 | 1.00 | 1.00 | 1.00 | 2.00 |

| Heater (FO) | H.P. | 0.00 | 0.00 | 5.00 | 5.00 | 7.50 | 7.50 | 10.00 |

| Total Power | H.P. | 2.50 | 2.50 | 8.50 | 9.50 | 12.50 | 14.50 | 20.00 |

| Dimension and Weight | ||||||||

| Length | MM | 1300 | 1500 | 1500 | 1500 | 1500 | 1800 | 2000 |

| Width | MM | 1100 | 1300 | 1300 | 1400 | 1400 | 1500 | 1500 |

| Height | MM | 1650 | 2200 | 2200 | 2500 | 2500 | 3000 | 3500 |

| Weight | Kg | 950 | 1100 | 1100 | 1200 | 1200 | 1400 | 1600 |

| Chimney Size | MM | 180 | 225 | 250 | 275 | 300 | 350 | 400 |

| NOTE: In view of constant endeavors to improve our products, we reserve the right to alter or change above specifications without prior notice. | ||||||||

Frequently Asked Questions

Can I switch between PNG and LPG?

Yes, the burner can be calibrated to handle both gases, though a change in gas train components may be needed for permanent switching.

How much can I save by switching from Diesel to PNG?

PNG typically reduces operational costs by 25% to 35% compared to HSD (Diesel).

What is the efficiency of the VEPOMAX series?

The base efficiency is 88%, which can reach 92%+ if an external economizer is installed.

Is natural gas better for the boiler's lifespan?

Yes. Gas is a "clean" fuel. Unlike oil, it doesn't leave soot on the heating surfaces, maintaining high efficiency for years without internal cleaning.

Is this boiler IBR or Non-IBR?

At 200 Kg/hr, we offer a Non-IBR Coil Type for easy compliance or an IBR Shell Type for specific industrial standards.

Does it require a large chimney?

No. Because gas combustion is clean, a small-diameter exhaust stack is sufficient.

What is the "3-Pass" design?

It means the hot flue gases travel through the water-heating area three times, capturing maximum heat before exiting.

What burner brands are used?

We use premium Riello (Italy) or ELCO (Germany) gas burners for high reliability.

What is the standard working pressure?

Standard units operate at 7 Kg/cm2, but we can provide designs up to 10.54 Kg/cm2.

How long does it take to start?

You can expect full steam pressure in roughly 5 minutes.

What safety devices are included in the gas train?

It includes a gas filter, high/low-pressure switches, and a safety shut-off valve.

Is it fully automatic?

Yes. The burner fires and cuts off automatically based on the steam pressure setting.

What happens if the water level drops?

The boiler is equipped with a Low-Water Cut-Off that shuts down the burner immediately and triggers an alarm.

Does it produce noise?

The gas burner is significantly quieter than an oil burner, making it suitable for indoor installations.

Is the unit skid-mounted?

Yes. It is a "Plug-and-Play" skid-mounted system including the pump and control panel.

What kind of water treatment is required?

A Water Softener is essential to prevent scale buildup in the coils.

How much space is needed?

The vertical unit occupies about 3 feet x 4 feet of floor space.

How often should I clean the gas filter?

We recommend checking the gas filter every 3–6 months to ensure steady fuel flow.

Do you provide service in Ahmedabad?

Yes, our Ahmedabad headquarters provides full support, installation, and AMC services.

Reviews

There are no reviews yet.