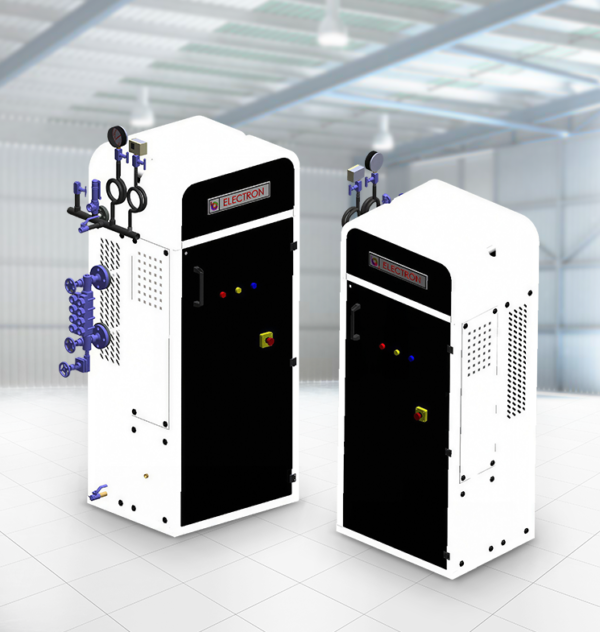

Electron: The Next Generation Electric Steam Boiler

IndianBoilers.com proudly presents Electron, a revolutionary product and a pioneer in electric boiler technology. electron sets a new benchmark in clean and green steam generation, offering zero emissions and no pollution, making it an ideal solution for environmentally conscious industries. With its compact footprint, it saves space while delivering unmatched efficiency. Engineered with high-quality stainless steel, the Electron steam generator ensures durability, hygiene, and reliable performance in every application.

IndianBoilers.com proudly introduces the Electron, a revolutionary electric steam boiler that marks a new era in sustainable steam generation. As a pioneer in electric boiler technology, the Electron is engineered to meet the demanding needs of modern, environmentally conscious industries, delivering steam with unmatched efficiency and zero environmental impact.

Key Advantages of the Electron Steam Generator

1. Clean & Green Performance

- Zero Emissions: The Electron offers truly clean steam generation with absolutely zero emissions and no pollution.

- Ideal Solution: This makes it the perfect choice for facilities committed to sustainability and strict environmental compliance.

2. Unmatched Efficiency & Compact Design

- Unmatched Efficiency: Utilizing electricity, the Electron converts nearly all input energy into usable steam, delivering superior thermal efficiency and reducing operational costs.

- Compact Footprint: Engineered to be space-saving, its compact footprint allows for flexible installation, even in facilities with limited space.

3. Durable, Hygienic, and Reliable

- High-Quality Construction: The Electron steam generator is meticulously engineered with high-quality stainless steel.

- Durability and Hygiene: This construction ensures exceptional durability, provides a highly hygienic steam path (crucial for food, beverage, and pharma), and guarantees reliable performance across all applications.

Application Electron?

The Electron – Electric Steam Boiler is an ideal solution for a wide range of industries, especially those requiring high-purity steam and seeking to eliminate combustion-related hazards and costs:

- Food & Beverage Processing

- Pharmaceuticals and Laboratories

- Hospitals and Healthcare Facilities

- Textile and Garment Industries

- Small-Scale Industrial/Process Heating

Experience the Future of Steam

The Electron is more than just a boiler; it’s a commitment to a cleaner, more efficient operational future.

Operating Range

- Capacity – 50 Kg/hr. to 400 Kg/hr***

- Fuel type – Electric Power

- Pressure- 7 & 10.54 kg/cm²

Technical Specifications

| Specification | Unit | ET-33 | ET-67 | ET-100 | ET-134 | ET-167 | ET-200 | ET-267 |

|---|---|---|---|---|---|---|---|---|

| General | ||||||||

| Steam Output From & at 100°C | Kg/hr | 50 | 100 | 150 | 200 | 250 | 300 | 400 |

| Working Pressure | Kg/CM² | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 |

| Steam Temperature | °C | 183 | 183 | 183 | 183 | 183 | 183 | 183 |

| Input Power Required | K.W. | 33 | 67 | 100 | 134 | 167 | 200 | 267 |

| Water holding | Liter | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Steam Outlet | MM | 15 | 20 | 20 | 25 | 25 | 25 | 25 |

| Input Power | Volt | 415 V- 3Phase 50 Hz | ||||||

| Type of Fuel | Fuel | Electric Power | ||||||

| Boiler Efficiency | ||||||||

| On Electric Heater | % | 98+/-2 | 98+/-2 % | 98+/-2 | 98+/-2 | 98+/-2 | 98+/-2 | 98+/-2 |

| Power Consumption | ||||||||

| Electric Power | KW/Hr | 33 | 67 | 100 | 134 | 167 | 200 | 267 |

| Electrical Load | ||||||||

| Feed Water Pump | K.W. | 0.40 | 0.40 | 0.40 | 0.40 | 0.75 | 0.75 | 0.75 |

| Input Heater Power | K.W. | 33.00 | 67.00 | 100.00 | 134.00 | 167.00 | 200.00 | 267.00 |

| Total Electric Load | K.W. | 33.40 | 67.40 | 100.40 | 134.40 | 167.75 | 200.75 | 267.75 |

| NOTE: In view of constant endeavors to improve our products, we reserve the right to alter or change above specifications without prior notice. | ||||||||

Ready to upgrade to a zero-emission, high-efficiency steam solution?

Would you like to request the detailed technical specifications (pressure, capacity, power requirements) for the Electron?

Frequently Asked Questions

Why should I choose an electric boiler over a fuel-fired one?

Electric boilers offer nearly 99% efficiency, zero local emissions, silent operation, and a very small footprint. They don't require fuel storage, chimneys, or complex fuel piping.

Does indianboilers.com offer IBR Electric Boilers?

Yes. We manufacture both IBR (Indian Boiler Regulations) and Non-IBR Electric Boilers based on your specific pressure and capacity requirements.

Is it true that electric boilers are faster to start?

Absolutely. Because the heating elements are directly immersed in the water, heat transfer is instantaneous. You can achieve full steam pressure much faster than with a traditional coal or oil boiler.

Do I need a separate boiler room for an electric unit?

Generally, no. Since there is no fire, smoke, or chimney requirement, these units are often installed directly next to the processing equipment, saving significant floor space and piping costs.

What capacities (kW) do you manufacture?

We offer a wide range of capacities, typically starting from 12 kW up to 600 kW and above, depending on your steam consumption requirements.

What is the maximum pressure an electric boiler can handle?

Our standard industrial models handle pressures up to 10.54 kg/cm², but we can custom-engineer units for higher pressure applications if needed.

What kind of heating elements are used?

We use high-grade, heavy-duty stainless steel (Incoloy or SS 316) heating elements. These are designed for high thermal conductivity and long-term durability.

What electrical power supply is needed?

Industrial electric boilers require a standard 3-Phase, 415V, 50Hz power supply.

How is the steam quality in an electric boiler?

Because of the steady and precise heat control, electric boilers produce very high-quality "dry" steam, which is essential for sensitive industrial processes.

Which industries benefit most from Electric Boilers?

They are ideal for industries requiring clean environments:

- Pharmaceuticals & Laboratories (Sterilization)

- Food & Beverage (Cooking/Processing)

- Hospitality (Laundry/Kitchens)

- Textiles (Ironing/Curing)

Can it be used for R&D or Pilot Plants?

Yes. Due to their precision and compact size, they are the preferred choice for R&D labs and small-batch production lines.

What safety features are integrated into the system?

At indianboilers.com, safety is paramount. Our boilers include:

- Pressure Switches: Automatic cut-off at high pressure.

- Safety Valves: Mechanical pressure release.

- Low Water Cut-off: Prevents heater burnout if water levels drop.

- Over-current Protection: Protects the electrical circuit.

Is maintenance difficult?

No. Maintenance is significantly lower than fuel-fired boilers. There are no burners to clean or soot to remove. The primary task is checking electrical terminals and periodic descaling.

Why is water treatment (Softener) essential for electric boilers?

Since the heating elements are in direct contact with water, scale buildup can cause them to overheat and fail. Using treated/softened water is critical to extending the life of your heaters.

How long do the heating elements last?

With proper water treatment and periodic maintenance, our high-quality elements can last several years of continuous operation.

What is the price of an Industrial Electric Boiler?

Pricing depends on the kW capacity and pressure rating. As a baseline, small-capacity industrial electric boilers start at approximately ₹5,00,000. Large, high-pressure IBR-certified units can range between ₹5,00,000 and ₹15,00,000+.

Why are electric boilers considered cost-effective despite high electricity rates?

While electricity can be more expensive than coal, you save money through:

- Lower installation costs (no chimney/fuel tanks).

- Minimal maintenance labor.

- Higher efficiency (no heat lost through the chimney).

- No need for a certified boiler operator for small units.

How do I get an exact quote for my facility?

Visit our Contact Us page or click the WhatsApp icon on our site. Provide your required Steam Output (kg/hr) or Power (kW), and our engineers will provide a detailed commercial proposal.

What is the typical Return on Investment (ROI)?

For industries where space is at a premium and cleanliness is mandatory, the ROI is seen immediately through reduced civil costs and zero product contamination risks.

Reviews

There are no reviews yet.