ELECTROAIR – Electric Hot Air Generator: Clean, Precise, and High-Efficiency Heating

For industrial processes that demand clean, precisely controlled hot air without the complications of fuel combustion, IndianBoilers.com introduces the latest in thermal technology: the Industrial Electric Hot Air Generator (EHAG).

Transition away from traditional, pollution-heavy systems and embrace a future of zero-emission, high-efficiency drying, curing, and heating. Our Electric Hot Air Generators are designed for critical applications where product quality and environmental standards are paramount.

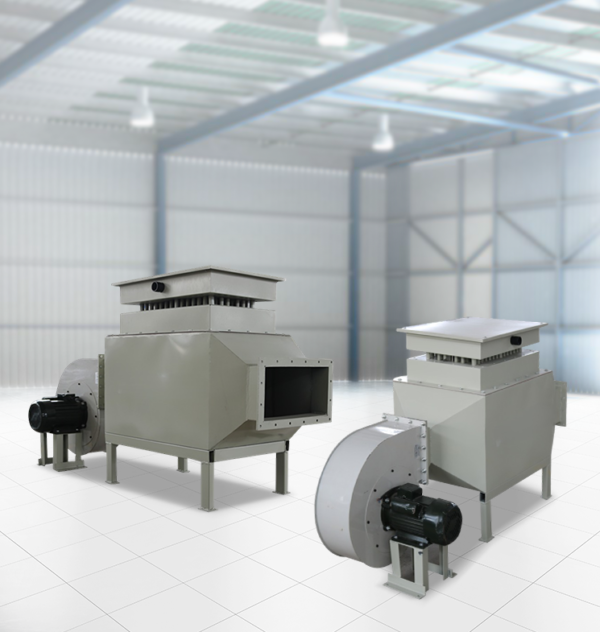

ELECTROAIR is a cutting-edge heating solution designed for maximum efficiency, safety, and user convenience. It features a high-temperature Fins tube type bundle heater with Ni-Cr wire, ensuring fast and uniform heating. It’s easy remove-or-insert design allows for quick maintenance and reduced downtime. The system is equipped with a Thyristor-based control panel for precise temperature management and a multiple zone design for an improved turndown ratio. ELECTROAIR is an eco-friendly solution with zero pollution output and requires no chimney, making it ideal for clean energy operations. User-friendliness is at the core of its design, with integrated heaters and an outer canopy for added safety, a cooling exhaust near the bank heater area, and a special panel AC to maintain optimal conditions. ELECTROAIR is the future-ready solution for safe, clean, and efficient industrial air heating.

Why Choose the ELECTROAIR Series?

Unlike conventional generators that rely on combustion, our electric systems eliminate the need for fuel storage, chimneys, and complex ventilation.

- 100% Thermal Efficiency: Converts nearly every kilowatt of electricity directly into usable heat with zero flue gas loss.

- Ultra-Clean Air: No combustion by-products, making it ideal for food-grade and pharmaceutical environments.

- Compact “Plug & Play” Design: Small footprint with no boiler house requirement—install it exactly where you need the heat.

- Whisper-Quiet Operation: Creates a safer and more comfortable work environment for your operators.

Key Technical Features

- Finned Tube Heating Elements: High-grade Ni-Cr (Nickel-Chromium) wire encased in stainless steel finned tubes ensures rapid heat transfer and long-term durability.

- Thyristor-Based Control: Advanced PLC/Thyristor power controllers provide modulating heat output, maintaining temperatures within a ±1°C margin.

- Easy-Maintenance Design: Features a “remove-or-insert” heater bundle design, allowing for rapid servicing and minimal downtime.

- Multi-Zone Configuration: Designed with multiple heating zones to improve the turndown ratio and save energy during low-demand cycles.

Applications: Where Clean Heat is Critical

The Industrial Electric Hot Air Generator is the preferred choice across various sectors where the heating medium must be free of combustion contaminants:

- Pharmaceuticals & Healthcare: Drying, sterilization, and process heating requiring clean air to maintain product purity.

- Food Processing: Baking, roasting, and drying of food products (e.g., spices, cereals, snacks) where direct contact with clean air is essential.

- Textiles & Fabrics: Rapid and uniform drying, curing, and heat-setting processes.

- Automotive & Coating: Paint curing, powder coating, and heat treatment where precise, uncontaminated heat is required for a flawless finish.

- Chemical & Ceramics: Drying powders, granules, and ceramic products.

Operating Range

- Capacity – 50,000 to 40,00,000 Kcal/hr.

- Fuel- Electric power

- Temperature- up-to 350℃

Technical Specifications

| Specification | Unit | EA-05 | EA-10 | EA-20 | EA-30 | EA-40 | EA-50 | EA-60 | EA-80 | EA-100 |

|---|---|---|---|---|---|---|---|---|---|---|

| General | ||||||||||

| heat Output K Cal/hr | KCal/hr | 50000 | 100000 | 200000 | 300000 | 400000 | 500000 | 600000 | 800000 | 1000000 |

| Hot air Outlet Temperature | °C | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 |

| Hot air Inlet Temperature | °C | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 |

| Air Flow @ 300*C | M³/hr | 650 | 1300 | 2600 | 3900 | 5200 | 6500 | 7800 | 10400 | 13000 |

| Air Pressure at HAG Outlet | MMWC | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| Input Power | Volts | 415 V- 3Phase 50 Hz | ||||||||

| Type of Fuel | Fuel | Electric Power | ||||||||

| Boilers Efficiency | ||||||||||

| On Electric Heater | % | 98 +/-2 | 98 +/-2 | 98 +/-2 | 98 +/-2 | 98 +/-2 | 98 +/-2 | 98 +/-2 | 98 +/-2 | 98 +/-2 |

| Power Consumption | ||||||||||

| Electric Power (860 Kcal/KW) | KW/Hr | 60 | 120 | 240 | 360 | 480 | 594 | 720 | 954 | 1188 |

| Electrical Load | ||||||||||

| P.A. Fan with Motor | H.P. | 3.00 | 5.00 | 7.50 | 10.00 | 15.00 | 20.00 | 20.00 | 25.00 | 30.00 |

| Input Heater Power | H.P. | 60 | 120 | 240 | 360 | 480 | 594 | 720 | 954 | 1188 |

| Total Electric Load | H.P. | 63.00 | 125.00 | 247.50 | 370.00 | 495.00 | 614.00 | 740.00 | 979.00 | 1218.00 |

| NOTE: In view of constant endeavors to improve our products, we reserve the right to alter or change above specifications without prior notice. | ||||||||||

Frequently Asked Questions

How does the heating process work in these units?

Air is drawn in by a centrifugal blower and passed over a series of specially designed electric heating elements. As the air moves through the heater housing, it absorbs thermal energy and is discharged at the desired temperature.

What is the maximum temperature an Electric Hot Air Generator can reach?

Our standard models at indianboilers.com typically achieve temperatures up to 250°C. However, we can custom-engineer units for high-temperature applications requiring up to 400°C or more.

Is the hot air produced safe for direct contact with food or medicine?

Yes. Since there is no combustion of fuels like oil or coal, there are no flue gases, soot, or carbon monoxide. The air remains 100% pure, making it ideal for "direct-to-product" drying.

How efficient are these generators compared to oil-fired ones?

Electric hot air generators are nearly 99% efficient because there are no stack losses (heat lost through a chimney). Almost every kilowatt of electricity used is converted directly into heat.

Can I control the temperature precisely?

Absolutely. Our units come with advanced control panels (PID or Thyristor-based) that allow for precision control within ±1°C, which is critical for sensitive industrial processes.

What capacities (kW) do you offer?

We offer a wide range of capacities starting from small 15 kW units up to large-scale 500 kW+ industrial systems, depending on your air volume and temperature requirements.

Can these units handle high air volumes (CFM)?

Yes. We design the heater housing and blower specifications based on your required Cubic Feet per Minute (CFM) to ensure the air reaches the target temperature at the necessary flow rate.

What power supply is required?

Most industrial models require a 3-phase, 415V, 50Hz power supply. We can also customize units for different voltage requirements for international clients.

Is it possible to recirculate the hot air?

Yes. Our designs can be configured for recirculating systems, which significantly saves energy by reheating air that is already warm rather than heating fresh ambient air.

Why is this generator preferred in the Pharmaceutical industry?

It is the gold standard for tablet coating and powder drying because it guarantees zero contamination, which is a mandatory requirement for GMP (Good Manufacturing Practice) standards.

Can it be used in the Food and Beverage sector?

Yes, it is widely used for dehydrating fruits, vegetables, spices, and grains, where maintaining the original aroma and color of the product is essential.

Is it suitable for the Textile industry?

It is perfect for specialized fabric curing, printing, and drying processes where uniform heat distribution is required to prevent damage to the material.

Does it require a chimney or a separate boiler room?

No. Because there are no emissions, you do not need a chimney or a dedicated boiler house. This saves significant space and reduces civil construction costs.

What safety features are built into your Electric Hot Air Generators?

At indianboilers.com, safety is paramount. Units include:

- Airflow Interlock: Heaters won't turn on without the blower.

- Over-temperature Cut-off: Prevents element burnout.

- Emergency Stop: For instant manual shutdown.

How long do the heating elements last?

With proper airflow and maintenance, our high-quality Ni-Cr (Nickel-Chromium) elements are designed to last for several years of continuous operation.

What maintenance is required?

Maintenance is minimal. It generally involves cleaning the air filters, checking electrical terminal tightness, and ensuring the blower motor is lubricated.

Are spare parts easily available?

Yes, we maintain a full inventory of heating elements, sensors, and blowers at our Ahmedabad facility to ensure minimal downtime for our customers.

How long does it take to install a unit?

Our units are "Plug & Play." Once delivered, they only require electrical and ducting connections, which can usually be completed within 1–2 days.

How can I get a quote for a custom unit?

Simply visit our Contact Us page or click the WhatsApp icon on our site. Provide us with your required Air Temperature (ΔT) and Air Flow (CFM), and our engineers will provide a technical quote.

Reviews

There are no reviews yet.