5 Ton Coal Fired Steam Boiler: Industrial Powerhouse

High-Capacity Steam Generation | Multi-Fuel Capability | 82%+ Efficiency

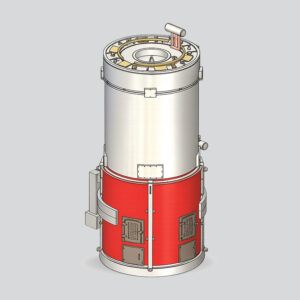

At IndianBoilers.com, our 5 Ton (5000 KG/HR) Coal Fired Steam Boilers are engineered to provide a steady, high-volume steam supply for large-scale industrial operations. Designed with a focus on fuel economy and rugged durability, these boilers are the preferred choice for industries where steam demand is high and operational costs must be kept low.

Our 5 TPH boilers feature advanced furnace designs that ensure complete combustion of coal and various biomass fuels, providing an eco-friendly yet powerful thermal solution.

Key Features & Advantages

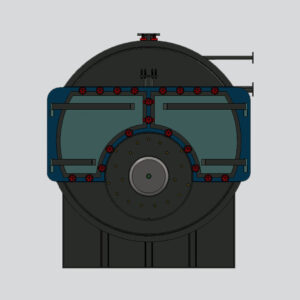

- High Thermal Efficiency: Optimized 3-pass smoke tube design combined with an external economizer ensures thermal efficiency of 82% or higher.

- Multi-Fuel Flexibility: While optimized for coal, our fluidized bed or grate-firing systems can easily handle Biomass Briquettes, Wood Chips, and Husk, giving you total control over fuel costs.

- Large Water & Steam Space: The generous shell diameter provides a large steam storage volume, allowing the boiler to handle sudden peak load fluctuations without a drop in pressure.

- Robust Grate Design: Available with Manual Fixed Grates or Automatic Pulsating/Moving Grates to ensure uniform air distribution and easy ash removal.

- Enhanced Safety: Fully compliant with IBR (Indian Boiler Regulations), featuring dual safety valves, high-pressure cut-offs, and advanced water-level controllers.

- Durability: Built with SA 515/516 Gr. 70 boiler-quality plates and high-grade seamless tubes to ensure a service life exceeding 20+ years.

Core Industry Applications

Our 5 Ton boilers are currently powering large-scale plants in:

- Textile Processing: For high-volume dyeing and drying ranges.

- Paper & Pulp: For continuous drying and chemical recovery processes.

- Plywood & Laminates: Driving multiple hot presses simultaneously.

- Distilleries & Breweries: For fermentation and distillation columns.

- Chemical & Fertilizer Units: For high-pressure reactor heating.

Advantages

Being based in Ahmedabad, IndianBoilers.com offers:

- Heavy-Duty Construction: Every 5 Ton unit is manufactured using precision submerged arc welding (SAW) for maximum joint strength.

- Turnkey Installation: From chimney fabrication and IBR pipeline layout to pollution control equipment—we handle it all.

- Advanced Dust Collection: We provide integrated Multi-cyclone Dust Collectors (MDC) to ensure your plant stays compliant with environmental emission norms.

Technical Specifications

| Specification | Unit | SM-05 | SM-7.5 | SM-10 | SM-15 | SM-20 | SM-25 | SM-30 | SM-40 | SM-50 | SM-60 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| General | |||||||||||

| Steam Output From & at 100°C | Kg/hr | 500 | 750 | 1000 | 1500 | 2000 | 2500 | 3000 | 4000 | 5000 | 6000 |

| Working Pressure | Kg/CM² | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 |

| Steam Temperature | °C | 183 | 183 | 183 | 183 | 183 | 183 | 183 | 183 | 183 | 183 |

| No’s of Passes | No’s | Three | Three | Three | Three | Three | Three | Three | Three | Three | Three |

| No’s of Furnace | No’s | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 2 | 2 | 2 |

| Grate Area | M² | 0.85 | 0.95 | 1.25 | 1.7 | 2.2 | 2.5 | 2.9 | 4.15 | 5.7 | 6 |

| Steam Outlet | MM | 40 | 50 | 50 | 80 | 80 | 80 | 100 | 100 | 125 | 150 |

| Heat Transfer Area | M² | 20 | 30 | 40 | 60 | 80 | 100 | 120 | 160 | 200 | 240 |

| Type of Fuel: Wood log, briquette, lignite, coal | |||||||||||

| Boiler Efficiency | |||||||||||

| On woodlog | % | 70 +/-2 | 70 +/-2 | 70 +/-2 | 70 +/-2 | 70 +/-2 | 70 +/-2 | 70 +/-2 | 70 +/-2 | 70 +/-2 | 70 +/-2 |

| On Coal | % | 76 +/-2 | 76 +/-2 | 76 +/-2 | 76 +/-2 | 76 +/-2 | 76 +/-2 | 76 +/-2 | 76 +/-2 | 76 +/-2 | 76 +/-2 |

| Fuel Consumption | |||||||||||

| WoodLog (3500) | Kg/hr | 110 | 165 | 220 | 331 | 441 | 551 | 661 | 882 | 1102 | 1322 |

| Briquette (4000) | Kg/hr | 96 | 145 | 193 | 289 | 386 | 482 | 579 | 771 | 964 | 1157 |

| Lignite (3000) | Kg/hr | 118 | 178 | 237 | 355 | 474 | 592 | 711 | 947 | 1184 | 1421 |

| Coal (4500) | Kg/hr | 79 | 118 | 158 | 237 | 316 | 395 | 474 | 632 | 789 | 947 |

| Electrical Load | |||||||||||

| Feed Water Pump | H.P. | 2.00 | 2.00 | 2.00 | 3.00 | 3.00 | 4.00 | 4.00 | 4.00 | 6.00 | 7.50 |

| I.D fan without BF | H.P. | 3.00 | 5.00 | 5.00 | 7.50 | 10.00 | 12.50 | 15.00 | 20.00 | 25.00 | 30.00 |

| F.D. Fan | H.P. | 1.00 | 1.00 | 2.00 | 3.00 | 5.00 | 5.00 | 7.50 | 7.40 | 10.00 | 12.50 |

| Total Electric Load | H.P. | 6.00 | 8.00 | 9.00 | 13.50 | 18.00 | 21.50 | 26.50 | 31.40 | 41.00 | 50.00 |

| NOTE: In view of constant endeavors to improve our products, we reserve the right to alter or change above specifications without prior notice. | |||||||||||

Frequently Asked Questions

What types of coal can be used in this model?

Our boilers are designed for high-versatility, accepting Bituminous, Sub-bituminous, Lignite, and even imported high-GCV coal.

Can this boiler run on fuels other than coal?

Yes, the STEAMAX SM-50 series features a multi-fuel furnace that can burn biomass briquettes, wood chips, and agricultural waste with minimal adjustment.

What is the thermal efficiency of the 5 TPH coal boiler?

The unit achieves a thermal efficiency of 82% ± 2% when equipped with an external economizer or air pre-heater.

How does an economizer improve ROI for a 5 Ton boiler?

An economizer recovers waste heat from flue gases to preheat feedwater, reducing coal consumption by approx. 5%, which leads to massive annual fuel savings for 5 TPH operations.

What is the steam output of the SM-50 model?

It provides a steady 5000 Kg/hr (5 Ton/hr) of high-quality dry saturated steam.

What are the standard working pressure options?

Standard designs are available for 10.54 kg/cm², 17.5 kg/cm², and 21 kg/cm². Custom pressures are available on request.

Is this boiler IBR (Indian Boiler Regulations) certified?

Yes, every 5 Ton unit is fully IBR compliant, built with IBR-approved SA 515/516 Gr. 70 plates and high-grade seamless tubes.

What is the advantage of the 3-pass smoke tube design?

It ensures the hot gases travel through the water-submerged tubes three times, maximizing heat absorption and maintaining a lower stack temperature.

Does it feature an automatic fuel feeding system?

Yes, for 5 TPH units, we offer Automatic Pulsating or Moving Grates and screw-conveyor feeding to ensure consistent pressure and reduced manual labor.

How long does it take to reach working pressure from a cold start?

A 5 Ton shell-type boiler typically takes 45 to 60 minutes to reach full operating pressure from a cold start.

What safety interlocks are standard on this model?

It includes dual safety valves, high-pressure cut-offs, a low-water alarm system, and a fusible plug to protect against overheating.

Do I need a certified boiler attendant for this unit?

Yes, according to IBR norms, a 5 TPH boiler must be under the charge of a Certified Boiler Attendant or Boiler Operation Engineer (BOE).

How does the boiler handle sudden peak load fluctuations?

The SM-50 is designed with a large shell diameter, providing a significant steam storage volume to handle sudden surges without a drop in pressure.

What kind of water treatment is mandatory?

A Water Softening Plant is required to maintain feedwater hardness below 5 ppm, preventing scale buildup and ensuring a long tube life.

How much space is required for installation?

A 5 Ton boiler system (including the MDC and chimney) requires a dedicated boiler house. We provide detailed layout drawings to help you plan your space.

What are the environmental compliance features?

We provide an integrated Multi-Cyclone Dust Collector (MDC) to ensure particulate emissions stay within the limits set by the Pollution Control Board (GPCB/CPCB).

How do I clean the smoke tubes?

The boiler features hinged front and rear doors, allowing easy access for mechanical cleaning and inspection of the tubes.

What is the expected lifespan of an Indian Boilers 5 TPH unit?

With proper water treatment and scheduled maintenance, our 5 Ton boilers are engineered to last 20 to 25 years.

Does Indian Boilers provide financing assistance?

Yes, we assist our clients with the necessary technical documentation to facilitate industrial machinery loans through major banks.

Reviews

There are no reviews yet.