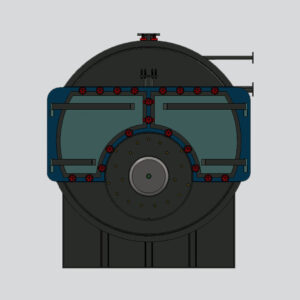

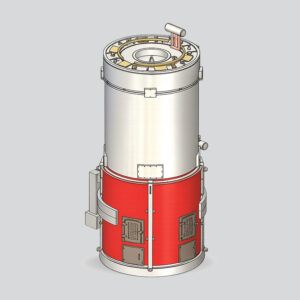

3 Ton Bagasse Fired Steam Boiler (3000 Kg/HR)

High-Performance Steam | Sustainable Agro-Waste Energy | Industrial Efficiency

At IndianBoilers.com, our 3 Ton Bagasse Fired Steam Boilers are precision-engineered to help industries turn fibrous agricultural waste into a powerful energy resource. Ideally suited for sugar mills, paper factories, and distilleries, these boilers utilize bagasse to provide a carbon-neutral steam supply that significantly reduces reliance on expensive fossil fuels.

Manufactured at our advanced facility in Ahmedabad, our 3 TPH boilers are built to handle the high moisture content of bagasse while maintaining consistent thermal output and high pressure.

Key Features & Performance

- Waste-to-Energy Optimization: Specifically designed to burn fibrous bagasse efficiently, converting a byproduct into low-cost, high-pressure steam.

- High Thermal Efficiency: Features an optimized 3-pass smoke tube design that achieves 82% efficiency or higher when paired with our heat recovery units.

- Large Combustion Furnace: Engineered with a spacious furnace volume to accommodate the high-volume nature of bagasse, ensuring complete combustion and reduced ash carryover.

- Advanced Fuel Feeding: Available with automated pneumatic or mechanical feeding systems to ensure a steady supply of fuel and uniform steam pressure.

- Robust Grate System: Equipped with specialized stationary or dumping grates designed to handle the specific ash and silica content found in bagasse.

- IBR Compliant Safety: Fully manufactured under Indian Boiler Regulations (IBR) using SA 515/516 Gr. 70 plates for maximum operational safety and longevity.

Operating Range & Specifications

Our 3 Ton Bagasse series is built for heavy-duty industrial endurance.

- 1. Capacity: 3 Ton (3000 Kg/HR) — Part of our wide range from 1.0 TPH to 15.0 TPH.

- 2. Fuel: Sugarcane Bagasse, Pith, and Wood Waste.

- 3. Working Pressure: Standard designs from 10.54 Kg/cm2 to 21 Kg/cm2.

- 4. Heat Recovery: Integrated Air Pre-Heaters (APH) or Economizers for maximum fuel economy.

Core Industry Applications

The 3 Ton Bagasse Boiler is the preferred choice for:

- Sugar Mills: Utilizing internal waste for process heating and juice evaporation.

- Paper & Pulp: Providing reliable steam for drying cylinders and chemical recovery.

- Distilleries: Driving distillation columns with sustainable biomass energy.

- Food Processing: Large-scale vegetable dehydration and sterilization.

Advantages

IndianBoilers.com brings global standards to local manufacturing:

- Superior Metallurgy: We utilize high-grade seamless tubes and boiler-quality plates to resist the corrosive elements often found in biomass flue gases.

- Pollution Control: Every unit is supplied with high-efficiency Multi-cyclone Dust Collectors (MDC) to meet stringent environmental emission norms.

- Turnkey Execution: From chimney design and piping to IBR certification and commissioning, our Ahmedabad team manages the entire project lifecycle.

Technical Specifications

| Specification | Unit | SM-05 | SM-7.5 | SM-10 | SM-15 | SM-20 | SM-25 | SM-30 | SM-40 | SM-50 | SM-60 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| General | |||||||||||

| Steam Output From & at 100°C | Kg/hr | 500 | 750 | 1000 | 1500 | 2000 | 2500 | 3000 | 4000 | 5000 | 6000 |

| Working Pressure | Kg/CM² | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 |

| Steam Temperature | °C | 183 | 183 | 183 | 183 | 183 | 183 | 183 | 183 | 183 | 183 |

| No’s of Passes | No’s | Three | Three | Three | Three | Three | Three | Three | Three | Three | Three |

| No’s of Furnace | No’s | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 2 | 2 | 2 |

| Grate Area | M² | 0.85 | 0.95 | 1.25 | 1.7 | 2.2 | 2.5 | 2.9 | 4.15 | 5.7 | 6 |

| Steam Outlet | MM | 40 | 50 | 50 | 80 | 80 | 80 | 100 | 100 | 125 | 150 |

| Heat Transfer Area | M² | 20 | 30 | 40 | 60 | 80 | 100 | 120 | 160 | 200 | 240 |

| Type of Fuel: Wood log, briquette, lignite, coal | |||||||||||

| Boiler Efficiency | |||||||||||

| On woodlog | % | 70 +/-2 | 70 +/-2 | 70 +/-2 | 70 +/-2 | 70 +/-2 | 70 +/-2 | 70 +/-2 | 70 +/-2 | 70 +/-2 | 70 +/-2 |

| On Coal | % | 76 +/-2 | 76 +/-2 | 76 +/-2 | 76 +/-2 | 76 +/-2 | 76 +/-2 | 76 +/-2 | 76 +/-2 | 76 +/-2 | 76 +/-2 |

| Fuel Consumption | |||||||||||

| WoodLog (3500) | Kg/hr | 110 | 165 | 220 | 331 | 441 | 551 | 661 | 882 | 1102 | 1322 |

| Briquette (4000) | Kg/hr | 96 | 145 | 193 | 289 | 386 | 482 | 579 | 771 | 964 | 1157 |

| Lignite (3000) | Kg/hr | 118 | 178 | 237 | 355 | 474 | 592 | 711 | 947 | 1184 | 1421 |

| Coal (4500) | Kg/hr | 79 | 118 | 158 | 237 | 316 | 395 | 474 | 632 | 789 | 947 |

| Electrical Load | |||||||||||

| Feed Water Pump | H.P. | 2.00 | 2.00 | 2.00 | 3.00 | 3.00 | 4.00 | 4.00 | 4.00 | 6.00 | 7.50 |

| I.D fan without BF | H.P. | 3.00 | 5.00 | 5.00 | 7.50 | 10.00 | 12.50 | 15.00 | 20.00 | 25.00 | 30.00 |

| F.D. Fan | H.P. | 1.00 | 1.00 | 2.00 | 3.00 | 5.00 | 5.00 | 7.50 | 7.40 | 10.00 | 12.50 |

| Total Electric Load | H.P. | 6.00 | 8.00 | 9.00 | 13.50 | 18.00 | 21.50 | 26.50 | 31.40 | 41.00 | 50.00 |

| NOTE: In view of constant endeavors to improve our products, we reserve the right to alter or change above specifications without prior notice. | |||||||||||

Frequently Asked Questions

What is the Gross Calorific Value (GCV) of Bagasse?

Sugarcane bagasse generally has a GCV of 2200 to 2400 Kcal/Kg at 50% moisture. Our boilers are engineered to extract maximum heat even from high-moisture agricultural waste.

Can this boiler run on other fuels during the sugar off-season?

Yes, our 3 Ton Bagasse series features a Multi-Fuel furnace. You can easily switch to wood logs, coal, or biomass briquettes when bagasse is unavailable.

How much can I save by using Bagasse instead of Diesel?

Since Bagasse is often a free or low-cost byproduct, industries can reduce their steam generation costs by up to 70% compared to using imported or liquid fossil fuels.

Is Bagasse firing considered carbon-neutral?

Yes. Burning bagasse releases only the carbon that the sugarcane absorbed during its growth, making it a sustainable and eco-friendly energy source for modern industries.

What is the thermal efficiency of this 3 TPH model?

Our Bagasse-fired boilers achieve an efficiency of approx. 72% to 76%. This can be boosted to 82%+ by integrating our specialized Air Pre-Heaters (APH) or Economizers.

How does the boiler handle the high moisture in Bagasse?

The STEAMAX SM-30 series is designed with a Large Combustion Furnace volume and a dual-air system to ensure complete drying and combustion of the fibrous fuel.

What is the standard working pressure?

The standard design is 10.54 Kg/cm², but we offer high-pressure variants for power generation or specific process needs up to 21 Kg/cm².

What is a "3-Pass Smoke Tube" design?

It ensures that the hot combustion gases travel through the water-submerged tubes three times, maximizing heat transfer before reaching the chimney.

Does it require an ID/FD Fan?

Yes. Because bagasse is light and fibrous, we use a Forced Draft (FD) fan for combustion air and an Induced Draft (ID) fan to maintain proper furnace suction and ash removal.

How is the bagasse fed into the boiler?

Standard units are manually fired through large doors. However, for a 3 Ton capacity, we highly recommend our automated pneumatic or screw-feeding system for consistent pressure.

What kind of grate system is used?

We use specialized Fixed Grates or Dumping Grates made from high-grade cast iron to handle the silica and ash content typical of sugarcane waste.

Is this boiler IBR (Indian Boiler Regulations) certified?

Yes, all our 3 Ton units are fully IBR compliant, manufactured using IBR-approved SA 515/516 Gr. 70 boiler-quality plates for maximum safety.

How long does it take to reach full pressure from a cold start?

Due to the large furnace and water volume, a cold start typically takes 60 to 90 minutes to reach optimum working pressure.

What safety interlocks are included?

The boiler features dual safety valves, a fusible plug (to prevent overheating), a low-water alarm, and an automatic cut-off for the draft fans.

How much ash is produced by a bagasse boiler?

Bagasse has a very low ash content (usually 1% to 2%). This makes ash management much easier than coal-fired systems.

How do I clean the smoke tubes?

Our design includes hinged smoke chamber doors at the front and back, allowing easy access for your team to clean soot and maintain peak efficiency.

Does it require a pollution control system?

Yes. To meet GPCB/Pollution Board norms, we provide a Multi-Cyclone Dust Collector (MDC) to trap fine particulate matter before it exits the chimney.

What is the recommended chimney height?

For a 3 Ton biomass boiler, a 30-meter chimney is usually required by law to ensure proper dispersion of emissions.

Does Indian Boilers provide turnkey installation in Ahmedabad?

Yes. From initial design and foundation layout to IBR certification and final commissioning, our Ahmedabad-based team manages the entire project lifecycle.

Reviews

There are no reviews yet.