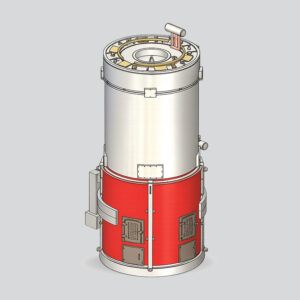

2 Ton Wood Pellet Fired Steam Boiler (2000 Kg/hr)

Fully Automated | Carbon-Neutral | High-Efficiency Steam Solutions

At indianboilers.com, our 2 Ton (2000 Kg/hr) Wood Pellet Fired Steam Boilers are designed for industries seeking a sustainable alternative to coal and oil without sacrificing automation. Wood pellets offer a standardized, high-calorific value fuel that allows for precise combustion control and significantly lower ash content.

Manufactured in our Ahmedabad facility, these boilers are engineered to meet the high-pressure demands of large-scale manufacturing while maintaining a clean, eco-friendly industrial footprint.

Key Features & Performance

- Automated Fuel Feeding: Equipped with a screw conveyor system for precise, automated pellet feeding, reducing manual labor and ensuring consistent steam pressure.

- Peak Efficiency: Achieves up to 84% ± 2% thermal efficiency through optimized furnace geometry and advanced heat recovery systems.

- Carbon-Neutral Heating: Utilizing wood pellets allows your facility to operate with a neutral carbon footprint, helping you meet environmental sustainability goals.

- Low Maintenance: Compared to wood logs or coal, wood pellets leave minimal ash, resulting in less frequent cleaning and higher uptime for your production line.

- High-Quality Dry Steam: Our large-diameter shell design ensures a high steam-to-water ratio, delivering dry, high-energy steam even during sudden load surges.

- Safety & Control: Fully IBR compliant, featuring PLC-based control panels for real-time monitoring of pressure, water levels, and combustion status.

Operating Range & Specifications

Our 2 Ton pellet boiler is part of a high-performance series built for durability and precision.

- Capacity: 2 Ton (2000 Kg/hr) — Available in a wide range from 0.5 TPH to 10 TPH.

- Fuel: High-grade Wood Pellets (6mm – 8mm) for standardized combustion.

- Working Pressure: Standard models from 10.54 Kg/cm2 to 21 Kg/cm2.

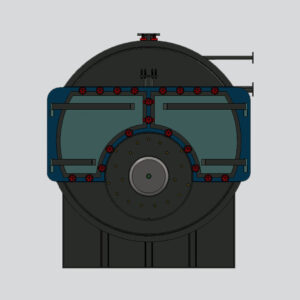

- Design Type: Horizontal 3-Pass Smoke Tube design for maximum heat absorption.

Core Industry Applications

The 2 Ton Wood Pellet Boiler is the ideal choice for:

- Pharmaceuticals: For clean and precise sterilization processes.

- Food & Beverage: For pasteurization and high-volume industrial cooking.

- Dairy Industry: Reliable steam for milk processing and CIP (Clean-in-Place) systems.

- Hospitals & Hotels: Large-scale laundry and centralized heating.

Advantages

By choosing IndianBoilers.com, you benefit from Ahmedabad’s premier engineering expertise:

- Precision Engineering: We use high-grade SA 515/516 boiler quality steel and seamless IBR tubes.

- Turnkey Support: From initial site survey to IBR documentation and commissioning, we provide end-to-end service.

- Advanced Pollution Control: Our systems include integrated Multi-cyclone Dust Collectors (MDC) to ensure emissions are well within local GPCB/Pollution Board norms.

Technical Specifications

| Specification | Unit | SM-05 | SM-7.5 | SM-10 | SM-15 | SM-20 | SM-25 | SM-30 | SM-40 | SM-50 | SM-60 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| General | |||||||||||

| Steam Output From & at 100°C | Kg/hr | 500 | 750 | 1000 | 1500 | 2000 | 2500 | 3000 | 4000 | 5000 | 6000 |

| Working Pressure | Kg/CM² | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 |

| Steam Temperature | °C | 183 | 183 | 183 | 183 | 183 | 183 | 183 | 183 | 183 | 183 |

| No’s of Passes | No’s | Three | Three | Three | Three | Three | Three | Three | Three | Three | Three |

| No’s of Furnace | No’s | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 2 | 2 | 2 |

| Grate Area | M² | 0.85 | 0.95 | 1.25 | 1.7 | 2.2 | 2.5 | 2.9 | 4.15 | 5.7 | 6 |

| Steam Outlet | MM | 40 | 50 | 50 | 80 | 80 | 80 | 100 | 100 | 125 | 150 |

| Heat Transfer Area | M² | 20 | 30 | 40 | 60 | 80 | 100 | 120 | 160 | 200 | 240 |

| Type of Fuel: Wood log, briquette, lignite, coal | |||||||||||

| Boiler Efficiency | |||||||||||

| On woodlog | % | 70 +/-2 | 70 +/-2 | 70 +/-2 | 70 +/-2 | 70 +/-2 | 70 +/-2 | 70 +/-2 | 70 +/-2 | 70 +/-2 | 70 +/-2 |

| On Coal | % | 76 +/-2 | 76 +/-2 | 76 +/-2 | 76 +/-2 | 76 +/-2 | 76 +/-2 | 76 +/-2 | 76 +/-2 | 76 +/-2 | 76 +/-2 |

| Fuel Consumption | |||||||||||

| WoodLog (3500) | Kg/hr | 110 | 165 | 220 | 331 | 441 | 551 | 661 | 882 | 1102 | 1322 |

| Briquette (4000) | Kg/hr | 96 | 145 | 193 | 289 | 386 | 482 | 579 | 771 | 964 | 1157 |

| Lignite (3000) | Kg/hr | 118 | 178 | 237 | 355 | 474 | 592 | 711 | 947 | 1184 | 1421 |

| Coal (4500) | Kg/hr | 79 | 118 | 158 | 237 | 316 | 395 | 474 | 632 | 789 | 947 |

| Electrical Load | |||||||||||

| Feed Water Pump | H.P. | 2.00 | 2.00 | 2.00 | 3.00 | 3.00 | 4.00 | 4.00 | 4.00 | 6.00 | 7.50 |

| I.D fan without BF | H.P. | 3.00 | 5.00 | 5.00 | 7.50 | 10.00 | 12.50 | 15.00 | 20.00 | 25.00 | 30.00 |

| F.D. Fan | H.P. | 1.00 | 1.00 | 2.00 | 3.00 | 5.00 | 5.00 | 7.50 | 7.40 | 10.00 | 12.50 |

| Total Electric Load | H.P. | 6.00 | 8.00 | 9.00 | 13.50 | 18.00 | 21.50 | 26.50 | 31.40 | 41.00 | 50.00 |

| NOTE: In view of constant endeavors to improve our products, we reserve the right to alter or change above specifications without prior notice. | |||||||||||

Frequently Asked Questions

What size of wood pellets should be used?

Our systems are optimized for standardized high-grade wood pellets with a diameter of 6mm to 8mm.

Why are pellets better than traditional wood logs for a 2 Ton capacity?

Pellets have a higher energy density and lower moisture content (<10%). This allows for automated feeding, higher efficiency, and significantly lower ash production compared to logs.

Is wood pellet firing carbon-neutral?

Yes. Wood pellets are a biomass fuel. The CO2 released during combustion is equal to the amount absorbed by the trees during growth, making your steam generation carbon-neutral.

How much can I save by switching from Diesel to Wood Pellets?

Depending on local fuel prices, wood pellets can reduce your operational steam costs by 40% to 50% compared to liquid fossil fuels.

Is the fuel feeding automated?

Yes. Unlike wood log boilers, the 2 Ton pellet model features a fully automated screw conveyor system that feeds pellets into the furnace based on steam demand.

Does it require constant manual supervision?

No. The integrated PLC-based control panel manages the entire combustion process, making it as easy to operate as a gas or oil-fired boiler.

How long does it take to generate steam from a cold start?

Thanks to the high-energy density of pellets and the optimized furnace geometry, it typically takes 35 to 50 minutes to reach full operating pressure.

Can the boiler handle sudden surges in steam demand?

Yes. The SM-20 features a large-diameter shell with a high steam-to-water ratio, providing a thermal buffer to maintain dry steam quality during load spikes.

What is "Reverse Flame Technology" in your pellet boilers?

It is an advanced combustion design that ensures the flame travels a longer path within the furnace, maximizing heat transfer and ensuring complete burnout of the fuel.

What is the standard working pressure for the SM-20 model?

The standard design is 10.54 Kg/cm², with high-pressure custom models available up to 21 Kg/cm².

Is this 2 Ton boiler IBR compliant?

Yes, our pellet boilers are fully IBR certified, constructed with IBR-approved SA 515/516 boiler-grade steel and seamless tubes.

What is the "3-Pass Smoke Tube" design?

The flue gases pass through the heating tubes three times before exiting, ensuring that over 80% of the heat is captured by the water.

What are the electrical requirements?

The system requires a 3-phase, 415V supply to power the automated feeder, the FD (Forced Draft) fan, and the feedwater pumps.

What grade of steel is used in construction?

We use high-grade SA 515/516 Gr. 70 boiler quality plates, known for superior strength and heat resistance.

How much ash does a 2 Ton pellet boiler produce?

Wood pellets produce very little ash (typically <1% by weight). This means much less frequent cleaning compared to coal or wood logs.

How do I clean the smoke tubes?

The boiler is designed with hinged front and rear doors, allowing easy access for mechanical tube cleaning to maintain peak efficiency.

Does it require a dust collector?

Yes. To meet GPCB and national pollution norms, we provide an integrated Multi-Cyclone Dust Collector (MDC) to ensure clean stack emissions.

What is the lifespan of the heating surface?

With proper water treatment (keeping hardness below 5 ppm) and regular cleaning, the boiler is engineered for an industrial service life of 15 to 20 years.

Does Indian Boilers provide on-site training?

Yes. Our Ahmedabad engineering team provides complete commissioning and on-site training for your staff on operating the automated pellet system.

Reviews

There are no reviews yet.