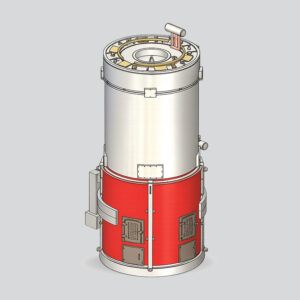

1 Ton Wood Log Fired Steam Boiler

High-Efficiency Industrial Steam | Sustainable & Cost-Effective Heating

At indianboilers.com, our 1 Ton (1000 Kg/hr) Wood Log Fired Steam Boilers are engineered to provide reliable thermal energy at the lowest operational cost. Designed specifically for the Indian industrial landscape, these boilers utilize locally available wood logs to deliver high-pressure steam for a variety of process applications.

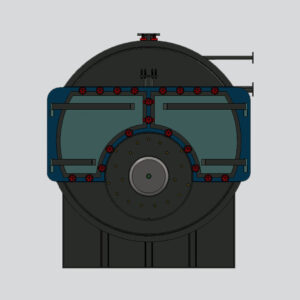

Built in our state-of-the-art Ahmedabad facility, this boiler combines traditional solid-fuel reliability with modern 3-pass smoke tube technology to ensure maximum heat recovery and minimal fuel waste.

Key Features & Performance

- Significant Fuel Savings: Wood logs are one of the most economical fuel sources in India, often reducing steam generation costs by up to 50% compared to oil or gas-fired units.

- 3-Pass Smoke Tube Design: Ensures that flue gases travel through the boiler three times, maximizing heat transfer to the water and achieving high thermal efficiency.

- Large Combustion Chamber: Specifically designed with a spacious furnace to accommodate large wood logs, reducing the effort required for fuel preparation and sizing.

- Robust Grate Design: Equipped with heavy-duty cast iron fire bars that ensure uniform air distribution for complete combustion and easy ash removal.

- Quick Steam Generation: Optimized water-to-steam ratios allow the boiler to reach working pressure rapidly, minimizing morning startup times.

- Safety & Compliance: Fully IBR (Indian Boiler Regulations) compliant, featuring high-quality boiler-grade steel, dual safety valves, and reliable water-level interlocks.

Ideal Industry Applications

Our 1 Ton Wood Fired Boilers are the “workhorses” for:

- Textiles: Fabric dyeing, printing, and garment finishing.

- Food Processing: Fruit pulping, pasteurization, and industrial kitchens.

- Plywood & Laminates: Supplying steam to hot presses and resin plants.

- Chemicals: Jacketed vessel heating and distillation.

- Pharma: Bulk drug manufacturing and sterilization.

Advantages

When you choose Indian Boilers, you are investing in decades of engineering heritage.

- Superior Material: We use only IBR-certified seamless tubes and boiler-quality plates (SA 515 Gr. 70).

- Low Maintenance: Our design features large manholes and handholes for easy internal cleaning and inspection.

- Local Expertise: As an Ahmedabad-based manufacturer, we provide immediate technical support and readily available spare parts across the country.

Operating Range

Our 1 Ton Steam Boiler is part of a versatile series designed to meet the rigorous thermal demands of diverse industrial processes.

- Capacity: 1 Ton (1000 Kg/hr) — Part of our wider range from 0.5 TPH to 6.0 TPH.

- Fuel Versatility: Optimized for Wood Logs and Biomass Briquettes, ensuring low-cost and sustainable heating.

- Working Pressure: Standard designs available from 10.54 Kg/cm2 to 21 Kg/cm2, tailored to your specific pressure requirements.

Technical Specifications

| Specification | Unit | SM-05 | SM-7.5 | SM-10 | SM-15 | SM-20 | SM-25 | SM-30 | SM-40 | SM-50 | SM-60 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| General | |||||||||||

| Steam Output From & at 100°C | Kg/hr | 500 | 750 | 1000 | 1500 | 2000 | 2500 | 3000 | 4000 | 5000 | 6000 |

| Working Pressure | Kg/CM² | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 |

| Steam Temperature | °C | 183 | 183 | 183 | 183 | 183 | 183 | 183 | 183 | 183 | 183 |

| No’s of Passes | No’s | Three | Three | Three | Three | Three | Three | Three | Three | Three | Three |

| No’s of Furnace | No’s | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 2 | 2 | 2 |

| Grate Area | M² | 0.85 | 0.95 | 1.25 | 1.7 | 2.2 | 2.5 | 2.9 | 4.15 | 5.7 | 6 |

| Steam Outlet | MM | 40 | 50 | 50 | 80 | 80 | 80 | 100 | 100 | 125 | 150 |

| Heat Transfer Area | M² | 20 | 30 | 40 | 60 | 80 | 100 | 120 | 160 | 200 | 240 |

| Type of Fuel: Wood log, briquette, lignite, coal | |||||||||||

| Boiler Efficiency | |||||||||||

| On woodlog | % | 70 +/-2 | 70 +/-2 | 70 +/-2 | 70 +/-2 | 70 +/-2 | 70 +/-2 | 70 +/-2 | 70 +/-2 | 70 +/-2 | 70 +/-2 |

| On Coal | % | 76 +/-2 | 76 +/-2 | 76 +/-2 | 76 +/-2 | 76 +/-2 | 76 +/-2 | 76 +/-2 | 76 +/-2 | 76 +/-2 | 76 +/-2 |

| Fuel Consumption | |||||||||||

| WoodLog (3500) | Kg/hr | 110 | 165 | 220 | 331 | 441 | 551 | 661 | 882 | 1102 | 1322 |

| Briquette (4000) | Kg/hr | 96 | 145 | 193 | 289 | 386 | 482 | 579 | 771 | 964 | 1157 |

| Lignite (3000) | Kg/hr | 118 | 178 | 237 | 355 | 474 | 592 | 711 | 947 | 1184 | 1421 |

| Coal (4500) | Kg/hr | 79 | 118 | 158 | 237 | 316 | 395 | 474 | 632 | 789 | 947 |

| Electrical Load | |||||||||||

| Feed Water Pump | H.P. | 2.00 | 2.00 | 2.00 | 3.00 | 3.00 | 4.00 | 4.00 | 4.00 | 6.00 | 7.50 |

| I.D fan without BF | H.P. | 3.00 | 5.00 | 5.00 | 7.50 | 10.00 | 12.50 | 15.00 | 20.00 | 25.00 | 30.00 |

| F.D. Fan | H.P. | 1.00 | 1.00 | 2.00 | 3.00 | 5.00 | 5.00 | 7.50 | 7.40 | 10.00 | 12.50 |

| Total Electric Load | H.P. | 6.00 | 8.00 | 9.00 | 13.50 | 18.00 | 21.50 | 26.50 | 31.40 | 41.00 | 50.00 |

| NOTE: In view of constant endeavors to improve our products, we reserve the right to alter or change above specifications without prior notice. | |||||||||||

Frequently Asked Questions

How much wood does the boiler consume per hour?

A 1 Ton (1000 Kg/hr) boiler typically consumes approximately 250 to 300 Kg of wood per hour, depending on the calorific value and moisture level of the wood.

Can I use other fuels like coal or briquettes in this boiler?

Yes, our wood-fired boilers feature a versatile grate design that allows you to switch to coal or biomass briquettes if wood supply is limited.

What is the thermal efficiency of this wood-fired model?

Our wood-fired boilers achieve a thermal efficiency of approx. 70% to 75%, which can be further enhanced by installing a heat recovery unit (Economizer).

How does wood-firing compare to diesel in terms of cost?

Wood is significantly more economical than diesel or gas. Switching to wood can reduce your steam generation costs by up to 50% to 60%.

What is the steam output capacity?

The rated capacity is 1000 Kg/hr (1.0 TPH) of steam from and at 100°C.

What working pressures are available?

Standard working pressures are 10.54 Kg/cm² and 17.5 Kg/cm². We can also provide custom designs for higher pressures.

Is this boiler IBR or Non-IBR?

We manufacture both IBR (Indian Boiler Regulations) and Non-IBR versions. For a 1 Ton capacity, an IBR certified unit is generally recommended for industrial safety compliance.

What is a "Horizontal Multitubular" design?

This means the fire passes through multiple tubes surrounded by water. It provides a larger heating surface area, ensuring faster steam generation compared to traditional vertical boilers.

Does the boiler require electricity to operate?

Yes, a small amount of electricity is required to power the feedwater pump and the Forced Draft (FD) fan used for combustion air.

How is the fuel fed into the boiler?

The standard 1 Ton wood boiler is manually fired through a large fire door designed for easy loading of long wood logs.

How often do I need to remove ash?

Ash should be removed from the bottom ash pit once or twice per shift (every 4–8 hours) to ensure proper airflow through the grates.

Is it difficult to clean the tubes?

Not at all. Our boilers feature hinged front and rear doors, allowing easy access to the smoke tubes for periodic cleaning and soot removal.

How long does it take to start the boiler from cold?

A wood-fired shell-type boiler typically takes 45 to 60 minutes to reach full operating pressure from a cold start.

What safety valves are included?

The boiler comes with two IBR-approved safety valves, a water level indicator, a pressure gauge, and a fusible plug that melts to prevent overheating if the water level drops too low.

What kind of foundation/civil work is required?

Since the 1 Ton unit is relatively heavy, it requires a stable PCC (Plain Cement Concrete) foundation. We provide the detailed foundation drawing upon order.

Does this boiler require a pollution control system?

Yes, to comply with GPCB/Pollution Board norms, we recommend installing a Multi-Cyclone Dust Collector to trap fly ash and soot before the smoke enters the chimney.

What height of chimney is required?

As per standard norms, a 1 Ton wood-fired boiler usually requires a 30-meter high chimney to ensure proper natural draft and local environmental compliance.

Can the boiler be installed outdoors?

While the boiler is robust, we recommend a simple shed (Boiler House) to protect the accessories, electrical panel, and insulation from rain and direct sunlight.

Does Indian Boilers provide installation support?

Yes, our Ahmedabad-based team provides complete installation, commissioning, and on-site training for your operators to ensure safe and efficient firing.

Reviews

There are no reviews yet.