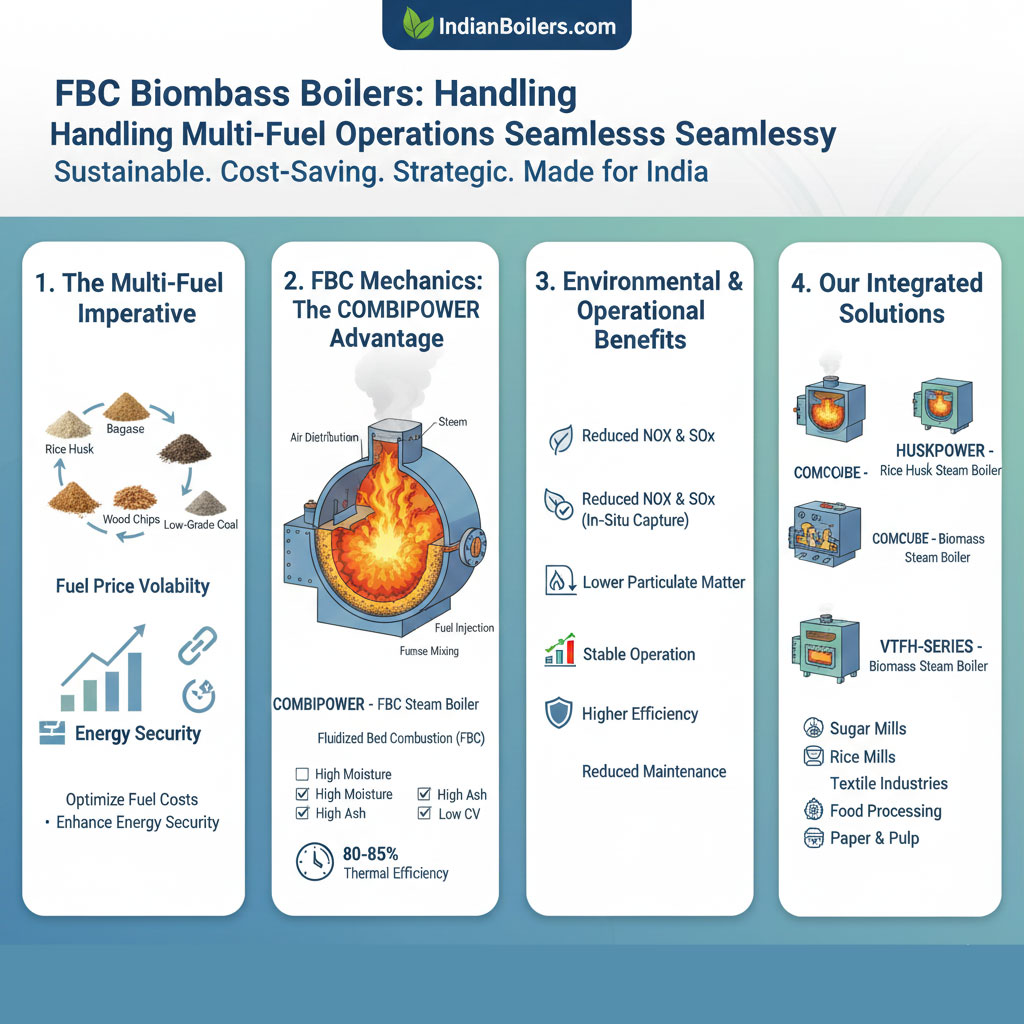

The COMBIPOWER Advantage

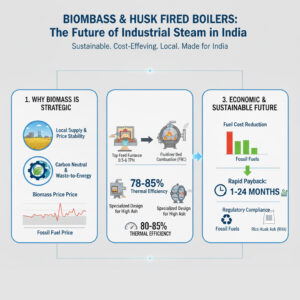

In the diverse industrial landscape of India, energy demands are constantly evolving, and the cost of conventional fuels like coal and furnace oil remains volatile. This instability pushes industries towards more sustainable and flexible energy solutions. Enter the Fluidized Bed Combustion (FBC) Biomass Boiler, a technology uniquely poised to handle a wide array of agro-waste and solid fuels with remarkable efficiency and minimal emissions.

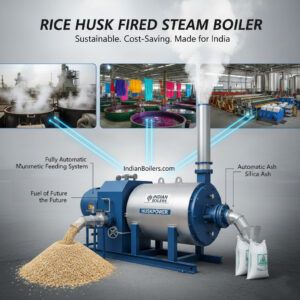

At IndianBoilers.com, our COMBIPOWER – FBC Steam Boiler stands at the forefront of this revolution. It is specifically designed to master the complexities of multi-fuel operations, offering unparalleled flexibility, efficiency, and cost savings for a diverse range of industries. Whether your plant has access to rice husk, bagasse, wood chips, briquettes, or even low-grade coal, COMBIPOWER ensures reliable and cost-effective steam generation.

1. Understanding the Multi-Fuel Imperative for Indian Industry

The ability to switch between different fuels is not just a convenience; it’s a strategic necessity for Indian factories.

A. Volatility of Single Fuel Sources

- Price Fluctuations: Relying on a single fuel source (e.g., a specific grade of coal) exposes industries to market price swings, supply chain disruptions, and geopolitical factors.

- Seasonal Availability: Many biomass fuels are seasonal (e.g., bagasse during crushing season). A multi-fuel boiler ensures continuous operation throughout the year.

- Local Market Dynamics: The availability and price of various agro-wastes can vary significantly by region and time. A flexible boiler allows industries to procure the most economical fuel at any given moment.

B. The Economic Advantage of Flexibility

By embracing multi-fuel capabilities, industries can:

- Optimize Fuel Costs: Always choose the cheapest available fuel.

- Enhance Energy Security: Reduce reliance on any single supplier or market.

- Minimize Waste Disposal Costs: Utilize various locally available agro-residues, turning waste into value.

This need for robust multi-fuel handling is precisely why FBC technology, embodied in our COMBIPOWER – FBC Steam Boiler, has become indispensable.

2. The Mechanics of Fluidized Bed Combustion (FBC): A Deep Dive

FBC technology is fundamentally different from conventional grate firing, making it superior for diverse solid fuels.

A. The Core Principle: Fluidization

- Bed Material: The heart of an FBC boiler is a bed of inert granular material, typically sand, alumina, or limestone.

- Air Distribution: High-velocity primary air is injected from the bottom of the furnace through a specially designed air distribution plate (often with nozzles or tuyeres).

- Fluidization: As air passes through, the solid particles of the bed material become suspended and turbulent, behaving like a boiling fluid. This state is called “fluidization.”

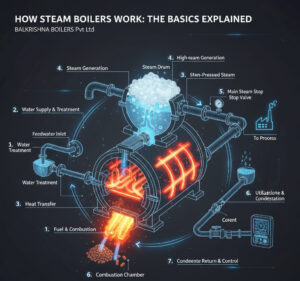

B. The Combustion Process in an FBC Boiler

- Fuel Injection: Fuel (biomass, coal, etc.) is fed into this hot, fluidized bed.

- Intense Mixing: The turbulent motion of the bed material ensures thorough mixing of fuel and air. This leads to:

- Excellent Heat Transfer: Very high heat transfer rates from the bed to the immersed heat exchange surfaces (tubes).

- Complete Combustion: The vigorous mixing, high bed temperature (typically 800-950 C), and long residence time for fuel particles ensure near-complete combustion, minimizing unburnt carbon losses.

- Lower Operating Temperatures: Unlike pulverized coal combustion ( 1500-1700C ), FBC operates at relatively lower temperatures. This is a critical advantage for multi-fuel applications.

3. Why FBC Excels in Multi-Fuel Operations

The unique characteristics of FBC technology make it inherently superior for burning a wide range of challenging fuels.

A. Fuel Flexibility

- Varying Calorific Values: FBC can efficiently burn fuels with wide variations in CV (e.g., from low CV rice husk to higher CV wood chips or coal). The large thermal mass of the fluidized bed provides thermal inertia, stabilizing combustion despite fuel quality fluctuations.

- High Moisture Content: The intense mixing and high heat transfer rates in the bed allow FBC boilers to handle fuels with higher moisture content more effectively than grate boilers, as moisture is rapidly evaporated.

- High Ash Content: Fuels like rice husk (18% – 25% ash) or certain coals can be problematic. In FBC, the inert bed material dilutes the ash, preventing slagging (fusion) even from low-fusion temperature ashes. Ash is either carried over as fly ash or drained from the bed.

- Abrasive Fuels: The fluidization action minimizes direct impact and abrasion from hard particles, protecting boiler components.

B. Environmental Advantages (Lower Emissions)

- Reduced NOx Emissions: The relatively lower combustion temperatures in FBC (below 950 C) prevent the formation of thermal NOx, a major air pollutant.

- SOx Capture (with Limestone): If fuels with sulfur content (e.g., some coals) are used, limestone can be added to the fluidized bed. The limestone reacts with sulfur dioxide (SOx), capturing it in-situ and significantly reducing SOx emissions without external scrubbers.

- Lower Particulate Matter (PM): Complete combustion reduces unburnt carbon, and efficient fly ash collection systems (Multi-Cyclone Dust Collectors – MCDC) ensure PM emissions are well within regulatory limits.

C. Enhanced Operational Benefits

- Stable Operation: The large thermal mass of the bed ensures stable steam generation even with minor fluctuations in fuel feed or quality.

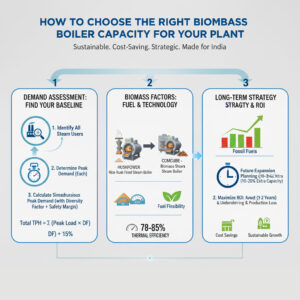

- Higher Efficiency: Due to complete combustion and excellent heat transfer, FBC boilers typically achieve higher thermal efficiencies (often 80%-85%) compared to conventional grate firing.

- Reduced Maintenance: Minimal slagging and less direct abrasion from fuel contribute to lower maintenance requirements and longer component life.

- Automated Ash Handling: Continuous ash removal from the bed and flue gas path minimizes manual intervention and ensures sustained performance.

4. The COMBIPOWER – FBC Steam Boiler: IndianBoilers.com’s Multi-Fuel Solution

Our COMBIPOWER – FBC Steam Boiler is meticulously engineered to bring these FBC advantages to Indian industries.

A. Tailored for India’s Fuel Mix

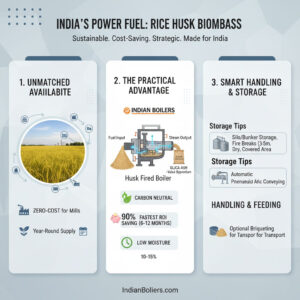

From the specific characteristics of rice husk (where our HUSKPOWER – Rice Husk Fired Steam Boiler also excels using FBC principles for smaller capacities) to diverse agro-waste and even solid fuels like lignite or low-grade coal, COMBIPOWER is designed for the Indian market’s reality.

B. Key Features of the COMBIPOWER Series

- Robust Water Tube Design: Built for durability and high pressure, ensuring reliable steam supply for large-scale industrial processes.

- Efficient Air Distribution: Precisely engineered air nozzles and distribution plate for optimal fluidization and combustion across varying fuel types.

- In-Bed Heat Transfer Surfaces: Strategically placed heat exchange tubes within the fluidized bed maximize heat recovery.

- Advanced Fuel Feeding Systems: Designed for automated, continuous feeding of different solid fuels, minimizing manual intervention.

- Integrated Heat Recovery Units: Economisers and Air Preheaters are standard, boosting overall thermal efficiency.

- Effective Ash Management: Systems for continuous bed ash and fly ash removal, handling the high ash content of many biomass fuels.

C. Versatility Across Sectors

The COMBIPOWER is ideal for:

- Sugar Mills (Bagasse): Efficiently burns bagasse, often as a co-generation unit.

- Rice Mills (Husk): For large steam demands, complementing or scaling up from our HUSKPOWER range.

- Textile Industries (Wood Chips, Briquettes): Provides flexible fuel options to maintain stable energy costs.

- Food Processing: Reliable steam for cooking, sterilization, and drying.

- Paper & Pulp: High steam output for process heating.

- Chemical Plants: Consistent energy supply for various reactions.

5. Beyond Steam: Comprehensive Biomass Solutions

While COMBIPOWER focuses on steam, IndianBoilers.com offers a full spectrum of biomass solutions:

- HUSKPOWER – Rice Husk Fired Steam Boiler: Dedicated and highly efficient for rice husk specific applications, often utilizing FBC technology for optimal performance.

- COMCUBE – Biomass Steam Boiler: A compact and versatile solution for smaller to medium steam demands, ideal for various agro-waste fuels with grate combustion.

- VTFH-SERIES – Biomass Fired Hot Water Boiler: For industries requiring high-temperature hot water efficiently from biomass.

Integrating these solutions allows a plant to optimize its entire thermal energy profile, leveraging the best technology for each specific need.

Conclusion: Embrace Flexibility, Enhance Profitability

The future of industrial energy in India demands flexibility, efficiency, and sustainability. FBC Biomass Boilers, particularly our COMBIPOWER – FBC Steam Boiler, deliver on all fronts. By seamlessly handling multi-fuel operations, they empower industries to:

- Dramatically reduce fuel costs by always selecting the most economical available biomass.

- Enhance energy security by diversifying fuel sources.

- Achieve superior environmental performance with lower NOx and SOx emissions.

- Ensure reliable, high-efficiency steam generation for uninterrupted production.

Choosing a COMBIPOWER from IndianBoilers.com is not just an investment in a boiler; it’s an investment in a future-proof, cost-effective, and environmentally responsible energy strategy.

Ready to unlock the full potential of multi-fuel operations for your factory?

Contact IndianBoilers.com today for an in-depth consultation and discover how the COMBIPOWER – FBC Steam Boiler can revolutionize your energy profile.