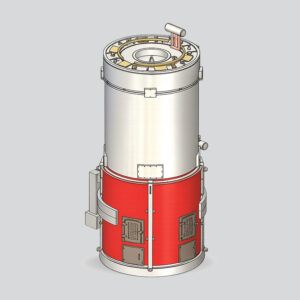

1.5 Ton Groundnut Shell Fired Steam Boiler

High-Efficiency Steam Generation | Low-Cost Agro-Waste Fuel | Sustainable Power

At indianboilers.com, our 1.5 Ton (1500 Kg/hr) Groundnut Shell Fired Steam Boilers are engineered to transform agricultural waste into high-pressure industrial steam. Groundnut shells are an abundant, high-calorific biomass fuel in India, making this boiler the ultimate choice for factories looking to slash fuel expenses while maintaining a carbon-neutral footprint.

Manufactured in our Ahmedabad facility, this boiler is specifically designed with a specialized furnace and grate system to handle the unique combustion characteristics of groundnut shells and husks.

Key Features & Performance

- Unbeatable Fuel Economy: Groundnut shells are among the most cost-effective fuels available, typically reducing operational costs by 60% compared to oil or gas.

- Specialized Combustion Design: Featuring a custom-built furnace that ensures complete combustion of groundnut husks, preventing unburnt fuel loss and maximizing heat output.

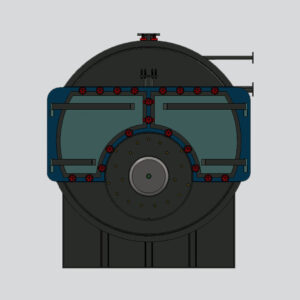

- 3-Pass Smoke Tube Technology: Flue gases travel through three distinct passes, ensuring maximum heat transfer to the water for high thermal efficiency.

- Robust Multi-Fuel Grate: While optimized for groundnut shells, the grate also supports Biomass Briquettes, Wood, and Coal, providing complete fuel flexibility.

- Advanced Dust Collection: Integrated with high-efficiency Multi-cyclone Dust Collectors (MDC) to ensure clean emissions and compliance with pollution board norms.

- Heavy-Duty Construction: Built in Ahmedabad using IBR-certified boiler-quality steel (SA 515/516) and seamless tubes for a 20+ year service life.

Operating Range & Specifications

Our 1.5 Ton boiler is part of a high-performance series built for durability and precision.

- Capacity: 1.5 Ton (1500 Kg/hr) — Part of our range from 0.5 TPH to 6.0 TPH.

- Fuel: Groundnut Shells, Husk, Biomass Briquettes, and Wood Logs.

- Working Pressure: Standard models from 10.54 Kg/cm2 to 21 Kg/cm2.

- Efficiency: Up to 82% with an integrated heat recovery unit.

Ideal Industry Applications

The 1.5 Ton Groundnut Shell Boiler is a “Gold Standard” for:

- Oil Mills: Utilizing their own byproduct (shells) to power steam requirements.

- Textile Processing: For dyeing and finishing at a fraction of the cost of diesel.

- Food Processing: Providing sustainable steam for frying, cooking, and sterilization.

- Chemical Plants: For precise temperature control in reactor vessels.

Advantages

By choosing IndianBoilers.com, you gain the expertise of Gujarat’s leading boiler manufacturer:

- Direct Factory Support: Our Ahmedabad location ensures rapid dispatch of spares and expert technicians.

- IBR Documentation: We handle all IBR registration and documentation, ensuring your plant is legally compliant from day one.

- Custom Engineering: We design the fuel feeding and ash removal systems specifically for your site’s groundnut shell handling requirements.

Technical Specifications

| Specification | Unit | SM-05 | SM-7.5 | SM-10 | SM-15 | SM-20 | SM-25 | SM-30 | SM-40 | SM-50 | SM-60 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| General | |||||||||||

| Steam Output From & at 100°C | Kg/hr | 500 | 750 | 1000 | 1500 | 2000 | 2500 | 3000 | 4000 | 5000 | 6000 |

| Working Pressure | Kg/CM² | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 |

| Steam Temperature | °C | 183 | 183 | 183 | 183 | 183 | 183 | 183 | 183 | 183 | 183 |

| No’s of Passes | No’s | Three | Three | Three | Three | Three | Three | Three | Three | Three | Three |

| No’s of Furnace | No’s | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 2 | 2 | 2 |

| Grate Area | M² | 0.85 | 0.95 | 1.25 | 1.7 | 2.2 | 2.5 | 2.9 | 4.15 | 5.7 | 6 |

| Steam Outlet | MM | 40 | 50 | 50 | 80 | 80 | 80 | 100 | 100 | 125 | 150 |

| Heat Transfer Area | M² | 20 | 30 | 40 | 60 | 80 | 100 | 120 | 160 | 200 | 240 |

| Type of Fuel: Wood log, briquette, lignite, coal | |||||||||||

| Boiler Efficiency | |||||||||||

| On woodlog | % | 70 +/-2 | 70 +/-2 | 70 +/-2 | 70 +/-2 | 70 +/-2 | 70 +/-2 | 70 +/-2 | 70 +/-2 | 70 +/-2 | 70 +/-2 |

| On Coal | % | 76 +/-2 | 76 +/-2 | 76 +/-2 | 76 +/-2 | 76 +/-2 | 76 +/-2 | 76 +/-2 | 76 +/-2 | 76 +/-2 | 76 +/-2 |

| Fuel Consumption | |||||||||||

| WoodLog (3500) | Kg/hr | 110 | 165 | 220 | 331 | 441 | 551 | 661 | 882 | 1102 | 1322 |

| Briquette (4000) | Kg/hr | 96 | 145 | 193 | 289 | 386 | 482 | 579 | 771 | 964 | 1157 |

| Lignite (3000) | Kg/hr | 118 | 178 | 237 | 355 | 474 | 592 | 711 | 947 | 1184 | 1421 |

| Coal (4500) | Kg/hr | 79 | 118 | 158 | 237 | 316 | 395 | 474 | 632 | 789 | 947 |

| Electrical Load | |||||||||||

| Feed Water Pump | H.P. | 2.00 | 2.00 | 2.00 | 3.00 | 3.00 | 4.00 | 4.00 | 4.00 | 6.00 | 7.50 |

| I.D fan without BF | H.P. | 3.00 | 5.00 | 5.00 | 7.50 | 10.00 | 12.50 | 15.00 | 20.00 | 25.00 | 30.00 |

| F.D. Fan | H.P. | 1.00 | 1.00 | 2.00 | 3.00 | 5.00 | 5.00 | 7.50 | 7.40 | 10.00 | 12.50 |

| Total Electric Load | H.P. | 6.00 | 8.00 | 9.00 | 13.50 | 18.00 | 21.50 | 26.50 | 31.40 | 41.00 | 50.00 |

| NOTE: In view of constant endeavors to improve our products, we reserve the right to alter or change above specifications without prior notice. | |||||||||||

Frequently Asked Questions

Why are groundnut shells a good fuel choice for boilers?

Groundnut shells have a high calorific value (~3500-3800 Kcal/Kg) and low ash content compared to other biomass, making them an extremely cost-effective "Green Fuel" for industrial steam.

Can I use other fuels like wood or briquettes in this boiler?

Yes. This boiler is designed with a versatile internal furnace and high-grade fire grates that allow you to switch to wood logs or biomass briquettes if groundnut shell supply is limited.

What is the thermal efficiency of this model?

Our groundnut-fired boilers achieve an efficiency of approx. 72% to 76%. This can be increased to over 80% by installing an external Economizer.

How much can I save by switching from Diesel to Groundnut Shells?

Switching to groundnut shells can reduce your monthly fuel bill by up to 60%, as biomass is significantly cheaper than liquid fossil fuels.

What is the steam output of this 1.5 TPH model?

The boiler produces 1500 Kg/hr of high-quality dry steam.

Is this boiler IBR or Non-IBR?

We manufacture this 1.5 Ton model in both IBR (Indian Boiler Regulations) and Non-IBR versions, depending on your factory's specific compliance requirements.

What is the standard working pressure?

The standard design pressure is 10.54 Kg/cm², with custom options available for high-pressure requirements up to 17.5 Kg/cm².

What is the "Horizontal Multitubular" design?

It is a 3-pass smoke tube design where the heat travels through multiple tubes surrounded by water, ensuring maximum heat absorption and rapid steam generation.

What grade of steel is used for construction?

The boiler shell and tube sheets are made from IBR-approved SA 515/516 Gr. 70 boiler quality plates for high-temperature durability.

How is the fuel fed into the boiler?

For a 1.5 Ton unit, the fuel is manually fed through a large, heavy-duty fire door. However, we also offer screw-feeder automation for consistent firing.

How do I manage the ash generated?

Groundnut shells produce very little ash. The ash falls through the grates into an ash pit, which can be easily cleaned manually once or twice per shift.

Is tube cleaning difficult for biomass boilers?

No. Our boilers feature hinged smoke chamber doors at both ends, allowing for easy access to the smoke tubes for periodic soot cleaning without heavy dismantling.

How long does it take to start the boiler?

From a cold start, it typically takes 45 to 60 minutes to reach full operating pressure.

What safety devices are included?

Standard features include dual safety valves, a fusible plug, a low-water alarm, and a high-pressure cut-off for the FD (Forced Draft) fan.

What kind of foundation is required?

A 1.5 Ton solid-fuel boiler requires a solid PCC (Plain Cement Concrete) foundation. We provide a detailed civil drawing for your contractor upon order.

Does this boiler require a dust collector?

To comply with GPCB/Pollution Control norms, we recommend installing a Multi-Cyclone Dust Collector to trap fine ash particles before they exit the chimney.

What height of chimney do I need?

Typically, a 30-meter chimney is required for a 1.5 TPH biomass boiler to ensure proper draft and meet environmental height regulations.

Can this boiler be installed in a compact space?

While solid-fuel boilers are larger than gas units, our Horizontal STEAMJET design is optimized for a compact footprint compared to traditional vertical boilers.

Do you provide training for boiler operators?

Yes. Our team from Ahmedabad provides on-site commissioning and hands-on training for your staff on safe firing techniques and fuel management.

Reviews

There are no reviews yet.