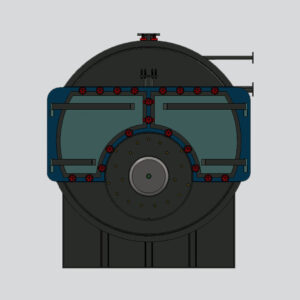

Oil Fired Steam Boiler: 300 Kg/hr (VEPOMAX Series)

Instant Steam. Industrial Strength. Ahmedabad Engineering.

At IndianBoilers.com, our 300 Kg/hr Oil Fired Steam Boiler is designed for high-efficiency performance where space is a premium and reliability is non-negotiable. Using a sophisticated 3-Pass Vertical Coil design, this boiler delivers high-quality dry steam in under 5 minutes, making it the most energy-efficient solution for your thermal needs.

Whether you are running a garment finishing unit, a food processing plant, or a pharmaceutical lab, our 300 Kg/hr unit offers the perfect balance of power and economy.

Key Performance Features

- Rapid Steam Generation: Don’t wait 45 minutes for steam. Our coil-type design goes from a cold start to full working pressure in just 4 to 6 minutes.

- High Thermal Efficiency: Achieve up to 88% ± 2% efficiency. Our specialized internal furnace design ensures every drop of fuel (HSD/LDO) is converted into maximum thermal energy.

- Fully Automatic Operation: Integrated with world-class burners (Riello/Bentone) and a smart control panel. Features include Push-Button Start, automatic pressure maintenance, and flame sensors.

- Space-Saving Vertical Design: Occupies 50% less floor space than traditional horizontal boilers. Ideal for urban industrial estates where every square foot counts.

- Safety Engineered: Equipped with multi-tier safety interlocks, including low-water cut-off, over-pressure trips, and a high-limit thermostat.

Applications in Focus

Our Ahmedabad-manufactured 300 Kg/hr boilers are trusted by:

- Garment Industry: For vacuum ironing tables and steam presses.

- Food Processing: For jacketed kettles, milk boiling, and sterilization.

- Pharmaceuticals: For small-batch autoclaving and chemical reactors.

- Hotels & Hospitals: For centralized laundry and high-capacity kitchen steam.

Operating Range

- Capacity : 200 KG to 850 KG

- Fuel : OIL, GAS, FO

- Pressure : 10.54 Kg/cm² to 21 Kg/cm²

Why IndianBoilers.com?

- Direct Manufacturer Pricing: Get the best rates directly from our Ahmedabad factory, eliminating middleman costs.

- Pan-India Service Network: With our team based in the heart of Gujarat’s industrial hub, we provide the fastest response times for installation and maintenance.

- No IBR Hassle: This model is designed to fall under the Non-IBR category, allowing you to operate without a certified boiler attendant and reducing regulatory paperwork.

- Ready Stock Spares: We maintain a full inventory of coils, burners, and pumps to ensure your production never stops.

Technical Specifications

| Specification | Unit | VX-02 | VX-03 | VX-04 | VX-05 | VX-06 | VX-08 | VX-10 |

|---|---|---|---|---|---|---|---|---|

| General | ||||||||

| Steam Output From & at 100°C | Kg/hr | 200 | 300 | 400 | 500 | 600 | 800 | 1000 |

| Working Pressure | Kg/CM² | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 |

| Steam Temperature | °C | 183 | 183 | 183 | 183 | 183 | 183 | 183 |

| Efficiency (On Oil) | % | 88% +/-2 | 88% +/-2 | 88% +/-2 | 88% +/-2 | 88% +/-2 | 88% +/-2 | 88% +/-2 |

| Efficiency (On Gas) | % | 87% +/-2 | 87% +/-2 | 87% +/-2 | 87% +/-2 | 87% +/-2 | 87% +/-2 | 87% +/-2 |

| Type of Fuel: HSD, LPG, NG, FO, LDO | ||||||||

| Fuel of Firing: Pressure Jet – Reverse Fuel Dual Block | ||||||||

| Fuel Consumption | ||||||||

| Diesel (10500) | Kg/hr | 12 | 18 | 23 | 29 | 35 | 47 | 58 |

| Furnace Oil (9600) | Kg/hr | 13 | 19 | 26 | 32 | 38 | 51 | 64 |

| LDO (10200) | Kg/hr | 12 | 18 | 24 | 30 | 36 | 48 | 60 |

| LPG (11000) | Kg/hr | 11 | 17 | 23 | 28 | 34 | 45 | 56 |

| Natural Gas (8900) | M³/hr | 14 | 21 | 28 | 35 | 42 | 56 | 70 |

| Electrical Load | ||||||||

| Feed Pump | H.P. | 1.00 | 1.00 | 1.00 | 2.00 | 2.00 | 3.00 | 3.00 |

| FD Fan | H.P. | 1.00 | 1.00 | 2.00 | 2.00 | 3.00 | 3.00 | 5.00 |

| Fuel Pump (Oil) | H.P. | 0.50 | 0.50 | 0.50 | 1.00 | 1.00 | 1.00 | 2.00 |

| Heater (FO) | H.P. | 0.00 | 0.00 | 5.00 | 5.00 | 7.50 | 7.50 | 10.00 |

| Total Power | H.P. | 2.50 | 2.50 | 8.50 | 9.50 | 12.50 | 14.50 | 20.00 |

| Dimension and Weight | ||||||||

| Length | MM | 1300 | 1500 | 1500 | 1500 | 1500 | 1800 | 2000 |

| Width | MM | 1100 | 1300 | 1300 | 1400 | 1400 | 1500 | 1500 |

| Height | MM | 1650 | 2200 | 2200 | 2500 | 2500 | 3000 | 3500 |

| Weight | Kg | 950 | 1100 | 1100 | 1200 | 1200 | 1400 | 1600 |

| Chimney Size | MM | 180 | 225 | 250 | 275 | 300 | 350 | 400 |

| NOTE: In view of constant endeavors to improve our products, we reserve the right to alter or change above specifications without prior notice. | ||||||||

Frequently Asked Questions

What types of oil can be used in this 300 Kg boiler?

It is designed to run primarily on Diesel (HSD) or Light Diesel Oil (LDO).

How much fuel does it consume per hour?

At full load, the consumption is approximately 19 to 21 Liters per hour, depending on the feedwater temperature and operating pressure.

What is the thermal efficiency of this unit?

The STEAMJET series 300 Kg/hr model offers a thermal efficiency of approx. 88%, which can be further optimized with a heat recovery unit.

How long does it take to generate steam from a cold start?

If it is a Vertical Coil type design, it can generate steam within 3 to 5 minutes. A Horizontal Shell type design takes about 15 to 20 minutes.

Is this boiler IBR or Non-IBR?

We offer the 300 Kg/hr model in both IBR and Non-IBR configurations. The Non-IBR version is highly popular for small units as it requires less regulatory paperwork.

What is the standard working pressure?

The standard design pressure is 7 Kg/cm² to 10.54 Kg/cm².

What is the advantage of the "Vertical Design" for 300 Kg?

The vertical configuration is extremely space-efficient, requiring minimal floor area, making it perfect for small workshops or laundries.

What burner technology do you use?

We equip these units with world-class Riello (Italy) or ELCO (Germany) monoblock burners for reliable, high-efficiency combustion.

What is the electrical connected load?

The total load for the burner motor and feedwater pump is approximately 1.5 HP to 2 HP, running on a standard 3-phase supply.

Is the 300 Kg Oil Fired boiler fully automatic?

Yes. It features a "Plug-and-Play" design with an automatic control panel that manages the firing cycle and water levels without manual intervention.

What safety features are included?

The boiler includes a high-pressure cut-off, flame failure sensor (photocell), low-water flow switch, and a spring-loaded safety valve.

Do I need a certified operator for a 300 Kg boiler?

If the unit is a Non-IBR model, a specially certified boiler attendant is usually not mandatory, though basic safety training is always recommended.

How is the water level maintained?

The system uses an automatic feedwater pump controlled by level sensors to ensure the boiler never runs dry.

What is "Dry Steam" and does this boiler provide it?

Dry steam contains minimal water droplets. Our 300 Kg unit features an internal moisture separator to ensure high-quality steam for your process.

Is the unit delivered as a skid-mounted package?

Yes, the boiler is 100% skid-mounted. The boiler, feed pump, and control panel are integrated for easy installation.

What kind of water treatment is required?

To prevent scaling in the tubes or coils, a Water Softener is required to keep water hardness below 5 ppm.

How do I clean the boiler?

For coil types, periodic chemical descaling is required. For shell types, the smoke tubes can be cleaned mechanically by opening the end doors.

What is the footprint of this boiler?

The 300 Kg vertical model is very compact, typically needing only about 3 feet x 3 feet of floor space.

Does Indian Boilers provide service in Ahmedabad?

Yes, our Ahmedabad headquarters provides full support, including installation, commissioning, genuine spares, and annual maintenance (AMC).

Reviews

There are no reviews yet.