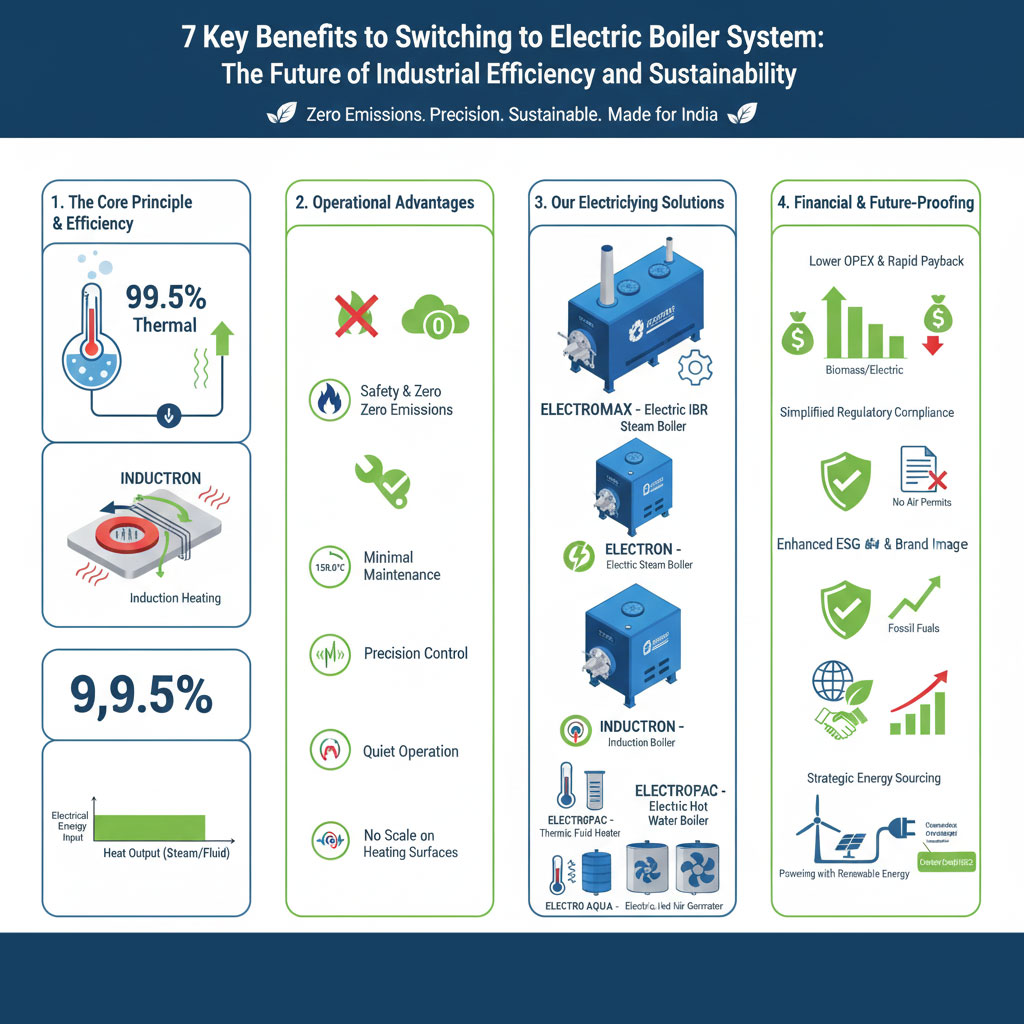

Benefits of Switching to an Electric Boiler System: The Future of Industrial Efficiency and Sustainability

The landscape of industrial heating is changing dramatically. Driven by global commitments to reduce carbon emissions and the escalating cost and complexity of managing fossil fuels, industrial plants worldwide are seeking simpler, cleaner, and more efficient thermal energy solutions. The answer, increasingly, lies in electric boiler systems.

Electric boilers represent the culmination of decades of heating technology, offering unparalleled efficiency, operational simplicity, and zero on-site emissions. They are no longer just a niche solution; they are a vital component of the modern, future-proof manufacturing facility.

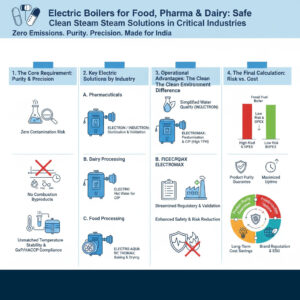

At IndianBoilers.com, we champion this transition with a complete suite of advanced electric heating solutions tailored for every need: the versatile ELECTRON – Electric Steam Boiler, the high-pressure ELECTROMAX – Electric IBR Steam Boiler, the high-temperature ELECTROPAC – Electric Thermic Fluid Heater, the reliable ELECTRO AQUA – Electric Hot Water Boiler, the clean ELECTROAIR – Electric Hot Air Generator, and the innovative, scale-resistant INDUCTRON – Induction Boiler.

Here are the 7 key benefits that make switching to an electric boiler system the most strategic move for your plant today.

Benefit 1: Zero On-Site Emissions and Instant Decarbonization

The most impactful benefit of electric heating is its immediate environmental advantage.

A. Eliminating All Combustion Pollutants

Electric boilers operate without any combustion process. This simple fact eliminates the production of the most common industrial pollutants directly at your facility:

- Carbon Dioxide : Zero direct CO2 emissions are released from the boiler itself.

- Nitrogen Oxides: NOx (a major contributor to smog and acid rain) is a high-temperature combustion byproduct—eliminated entirely in electric systems.

- Sulphur Oxides : Zero SOx emissions, which are primarily associated with the combustion of fossil fuels like coal and furnace oil.

- Particulate Matter : No ash, soot, or fine particles are generated.

For plants operating in densely populated or sensitive environmental zones, switching to a zero-emission system like the ELECTROMAX or ELECTRON means achieving environmental compliance effortlessly and immediately improving local air quality.

B. The Green Grid Synergy

The true environmental benefit of electric boilers lies in their integration with the national power grid. As renewable energy (solar, wind, hydro) penetration increases—a massive trend in India—the electricity powering your boiler becomes progressively cleaner. An electric boiler installed today becomes a carbon-neutral heating system tomorrow, automatically aligning your business with global net-zero goals without needing costly future equipment replacements.

Benefit 2: Highest Thermal Efficiency on the Market

Electric boilers offer a performance metric unattainable by traditional fossil fuel systems: near-perfect thermal efficiency.

A. Maximizing Energy Conversion

- Combustion Loss: Fossil fuel boilers inevitably lose 10% to 25% of the energy value of their fuel as wasted heat up the exhaust stack.

- Electric Gain: Electric boilers, such as our ELECTRON and ELECTROMAX series, generate heat directly within the fluid (water or thermal fluid). Nearly 100% of the electrical energy is converted into usable heat energy.

This superior efficiency directly translates to lower energy bills relative to the heat output. For operations that require precise energy input, this 99.5% conversion rate provides reliable and consistent cost forecasting.

B. INDUCTRON and Sustained Efficiency

The INDUCTRON – Induction Boiler technology further maximizes long-term efficiency. By heating the fluid using an electromagnetic field and a non-contact core, it minimizes the scaling and fouling that naturally occurs on the heating elements of traditional resistance boilers. This means the INDUCTRON sustains its peak efficiency for much longer periods, reducing the need for chemical cleaning and maintenance downtime.

Benefit 3: Unmatched Operational Simplicity and Safety

Electric boilers radically simplify the operation and maintenance protocols of an industrial heating system.

A. No Fuel Handling, No Complexity

The elimination of combustion removes a massive logistical and operational burden:

- No Fuel Storage: Eliminate tanks, bunkers, pumps, and fuel delivery logistics.

- No Fuel Pre-treatment: No need for fuel oil heating or conditioning.

- No Chimneys/Flues: Eliminate complex chimney maintenance and regulatory checks.

- Reduced IBR Complexity: While the ELECTROMAX – Electric IBR Steam Boiler is built to IBR standards, its fire-side operation is eliminated, simplifying a major component of regulatory compliance and inspection.

B. Superior Safety Profile

The absence of flame and fuel eliminates the main risks associated with industrial heating:

- No Explosion Hazard: Eliminates the risk of explosions from gas or oil build-up.

- No Fire Risk: Eliminates the risk of fire from stored fuel or burner malfunctions.

- No Flue Gas Risk: Eliminates the risk of carbon monoxide or other flue gases leaking into the plant.

This enhanced safety profile often leads to lower insurance premiums and a safer working environment.

Benefit 4: Precise Temperature and Pressure Control

For modern manufacturing processes that demand tight control over temperature and pressure, electric heating is the superior choice.

A. Rapid Modulation

Electric heating elements (or the induction core) can be switched on or off, or modulated, almost instantly.

- Staged Output: Our ELECTRON and ELECTROMAX boilers typically use multiple heating stages. The control system can rapidly cycle these stages to match steam demand with exceptional accuracy, maintaining pressure within 1 psi (or better).

- Precise Process Heat: For specialized applications like food, chemical, and pharmaceutical processing, this precision is non-negotiable. The ELECTROPAC – Electric Thermic Fluid Heater provides highly stable, non-pressurized high heat, while the ELECTRO AIR – Electric Hot Air Generator offers clean, accurate temperatures for sensitive drying processes.

B. Quick Start-Up and Standby

Electric boilers can achieve operating temperature and pressure much faster than fire-tube or water-tube combustion boilers. This is ideal for intermittent processes or for facilities that require rapid standby activation, eliminating the long warm-up times and associated fuel waste of traditional systems.

Benefit 5: Flexibility and Decentralization

Electric heating systems offer unprecedented flexibility in their physical placement and application.

A. Compact Footprint

Without the need for fuel train, burner systems, air intake ducting, and large chimneys, electric boilers require significantly less space. The ELECTRON is a highly compact unit, ideal for installation near the point of steam use.

B. Decentralized Heating Strategy

The compact size and zero-emission profile allow for decentralization. Instead of one large central boiler room with extensive, loss-prone steam piping, a plant can install smaller ELECTRON units (or ELECTRO AQUA for hot water) closer to individual processing lines.

- Minimized Distribution Losses: Reducing pipe length drastically cuts down on heat loss, a major source of inefficiency in older plants.

- Redundancy: Decentralization provides inherent redundancy; if one unit requires maintenance, other processes remain operational.

Benefit 6: Simplified Regulatory Compliance

For industrial managers, the reduction in regulatory burden is a significant operational advantage.

A. Eliminating Air Permit Requirements

The single greatest regulatory benefit is the elimination of requirements for local air quality permits (e.g., permits related to NOx or SOx emissions). Since electric boilers are zero-emission, they bypass these complex, time-consuming, and costly processes entirely.

B. ELECTROMAX and IBR Standards

The ELECTROMAX – Electric IBR Steam Boiler is designed to meet the rigorous safety and quality standards of the Indian Boiler Regulations, ensuring compliance where high-pressure steam is mandatory. However, by removing the fire-side components, inspections become simpler and less specialized.

Benefit 7: Strong Long-Term Financial Case (Lower Total Cost of Ownership)

While the initial capital cost (CAPEX) for electric boilers, particularly large units like the ELECTROMAX, can be higher than simple fossil fuel systems, the Total Cost of Ownership (TCO) is often superior over the life cycle of the equipment.

A. Reduced Operational Expenditure (OPEX)

- Maintenance Savings: Savings from reduced maintenance (no burner parts, no refractory repairs, no stack cleaning) are substantial, potentially 30% to 50% lower than comparable combustion boilers.

- Fuel Savings: While the unit cost of electricity may be higher than raw fuel, the 99.5% efficiency minimizes the energy required for the same heat output.

- Waste Elimination: Eliminating the cost of ash or waste fuel disposal.

B. Monetizing the Green Investment

Electric boilers provide avenues for financial return unavailable to fossil fuel systems:

- Carbon Credit Generation: If the electricity is sourced from certified renewable sources (or paired with on-site solar), the plant can generate tradable carbon credits or Renewable Energy Certificates (RECs), creating a valuable revenue stream.

- Favorable Financing: Green technology often qualifies for preferential financing, subsidies (where applicable), and tax benefits, further improving the ROI.

Conclusion: The Electric Transition is Strategic

Switching to an electric boiler system is a holistic, strategic decision that impacts finance, operations, compliance, and corporate sustainability. From the ELECTRON’s plug-and-play simplicity to the ELECTROMAX’s heavy-duty performance, and the INDUCTRON’s innovative efficiency, electric heating is the clear choice for the clean industrial future.

The 7 key benefits—zero emissions, superior efficiency, safety, precision, operational simplicity, regulatory ease, and lower TCO—make the electric transition an unmissable investment.

Is your plant ready to future-proof its operations and achieve immediate decarbonization?

Contact IndianBoilers.com today for an expert energy audit and a detailed analysis of how the ELECTRON, ELECTROMAX, ELECTROPAC, ELECTRO AQUA, ELECTROAIR, or INDUCTRON can revolutionize your process heating.