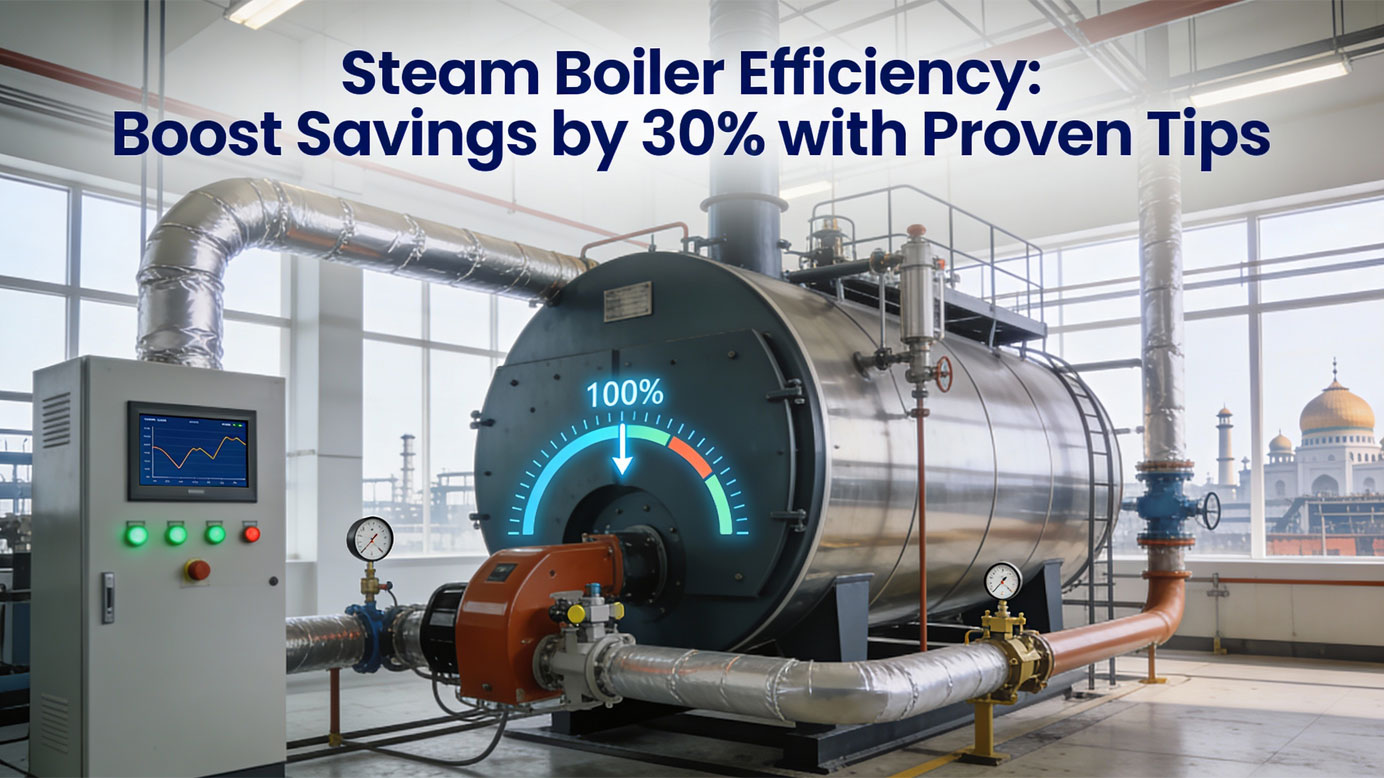

Steam Boiler Efficiency: Boost Savings by 30% with Proven Tips

Steam boilers power countless Indian industries, from textiles to food processing, but inefficiencies drain fuel costs and profits. Optimizing efficiency can cut energy expenses by up to 30%, directly boosting your bottom line at indianboilers.com. This guide delivers proven, actionable tips tailored for Indian manufacturers.

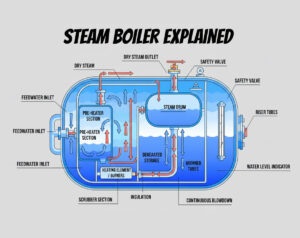

Understanding Boiler Efficiency Basics

Boiler efficiency measures how effectively fuel converts to usable steam, typically ranging from 70-85% in industrial models. The direct method calculates it as (heat output / heat input) x 100, while the indirect method subtracts losses like stack gases and radiation. In India, where fuel prices fluctuate, even a 1% gain saves thousands annually—for a 10 TPH boiler running 8,000 hours, that’s lakhs in coal or oil.

Common losses include dry flue gas (20-30%), incomplete combustion (5-10%), and blowdown (3-8%). High stack temperatures above 200°C signal waste heat potential, while poor air-fuel ratios spike excess air to 30-50%. Indian Boiler Regulations (IBR) mandate regular audits, making efficiency upgrades compliant and competitive.

Tip 1: Lower Stack Temperatures with Economizers

Stack gases exiting at 250-300°C waste 1% efficiency per 20°C drop. Install an economizer to preheat feedwater using flue heat, slashing stack temps to 120-150°C and boosting efficiency by 5-7%. For Indian plants, non-condensing economizers suit coal-fired boilers, recovering 3-5% fuel while handling local fuel ash.

Case study: A Maharashtra textile mill retrofitted a 6 TPH boiler, dropping stack temp from 280°C to 160°C, saving 12% on fuel (₹15 lakhs/year) with ₹5 lakh investment—payback in 4 months. Clean fins quarterly to maintain flow; integrate with PLC controls for auto-adjustment.

Tip 2: Optimize Combustion Control

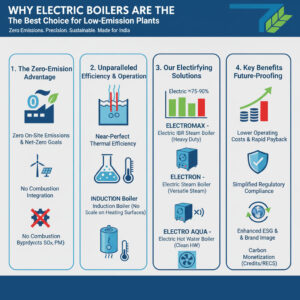

Excess air inflates flue volume, cutting efficiency by 1-2% per 5% overage. Aim for 2-4% O2 in flue gas via oxygen trim systems, which auto-tune air-fuel ratios across loads. High-efficiency burners with low-NOx design improve mixing, reducing unburnt fuel losses from 2% to under 0.5%.

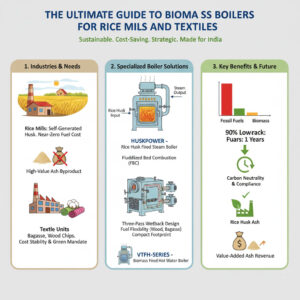

In India, variable frequency drives (VFDs) on FD/ID fans match blower speed to load, saving 15-20% electricity. A Punjab rice mill saw 18% fuel cut post-VFD install, plus smoother IBR compliance. Calibrate quarterly using flue gas analyzers—tools cost ₹50,000 but pay back fast.

Tip 3: Preheat Combustion Air

Cold air demands flame heat to reach ignition, stealing 1% efficiency per 40°C preheat. Air preheaters (APH) use flue waste to hit 150-200°C intake, lifting overall efficiency 3-5%. For biomass/coal boilers common in India, regenerative APH handles dirty gases better than tubular types.

Gujarat chemical plant example: APH on 15 TPH boiler pre-heated air to 180°C, saving 1.78% efficiency (₹1.5 crore/year fuel) with 2-year payback. Pair with insulation upgrades for synergy; avoid over-preheating to prevent NOx spikes.

Tip 4: Enhance Insulation and Minimize Leaks

Uninsulated pipes lose 5-10% steam as condensate. Use 100-150mm calcium silicate or rockwool on boilers, pipes, and valves, targeting <1% surface loss. Tighten steam traps—faulty ones waste 20-30% output; ultrasonic detectors spot leaks in minutes.

Indian MSMEs often overlook valves; insulating 500m piping saved a Tamil Nadu pharma firm 8% energy (₹8 lakhs/year). Replace steam traps annually per IBR; ROI under 6 months. Steam distribution audits via infrared thermography (₹20,000/service) pinpoint hotspots.

Tip 5: Improve Feedwater Quality and Blowdown

Scale reduces heat transfer by 10-20% per mm buildup, forcing higher firing rates. Maintain TDS <2,000 ppm via deaerators and softeners, preventing pitting/corrosion. Optimal blowdown (3-5%) via conductivity controls minimizes loss; flash steam recovery vessels reclaim 10-15% heat.

For hard water prevalent in India, RO pre-treatment cuts blowdown 50%. A UP sugar mill recovered blowdown heat, gaining 2% efficiency (₹10 lakhs savings). Automate blowdown to cycles of 10-15 concentration ratio.

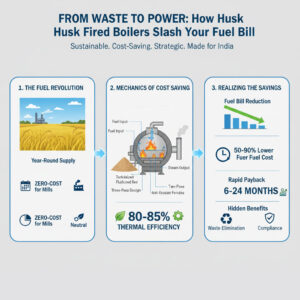

Advanced Upgrades for 20-30% Gains

Combine basics for compounding: economizer + combustion trim + APH yields 15-20%. Superheaters and waste heat boilers (WHB) push to 30% via process integration. Biomass co-firing in FBC boilers leverages India’s agro-waste, dropping costs 20-25%.

VFDs and smart PLCs enable load-matching, curbing short-cycling losses (5-10%). A Haryana refinery’s full retrofit hit 82% efficiency from 65%, saving ₹2 crore/year.

Maintenance Schedule for Peak Performance

Daily: Check water levels, pressures, blowdown valves. Weekly: Inspect burners, clean sight glasses. Monthly: Flue gas analysis, trap tests. Annual: IBR inspection, tube cleaning. Soot blowers prevent fireside buildup, restoring 2-3% efficiency.

Log data via IoT sensors for trends—apps like those from indianboilers.com predict failures. Train staff on combustion tuning; certification costs ₹5,000/person but avoids ₹50 lakh downtimes.

Real Indian Case Studies

Indian Boilers client: Optimized controls + insulation on 4 TPH unit saved 22% fuel. power plant: Economizer suite hit 30% savings via preheated air and low stack.

Textile Gujarat: Biomass conversion + VFDs cut oil use 40%. These prove 30% feasible with phased ₹10-20 lakh investments for 5-10 TPH boilers.

Calculating Your Savings

Use: Efficiency New = Old + Gains; Annual Savings = Fuel Cost x Hours x (1 – New/Old). For 10 TPH, 75% to 97.5% (22.5% gain): 30% fuel cut on ₹5 crore spend saves ₹1.5 crore. Tools like Steamax calculators verify.

Contact indianboilers.com for audits—experts deliver customized 30% plans compliant with IBR and PAT schemes. Start with stack temp check today for quick wins.