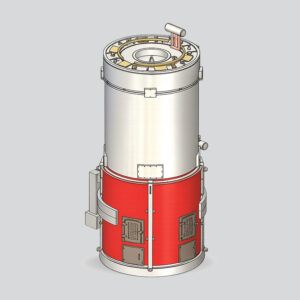

Water Tube Boiler: 750 KG to 4000 KG/HR

High-Pressure Performance. Instant Steam. Maximum Safety.

The Water Tube Boiler series at indianboilers.com represents the pinnacle of thermal engineering for industries requiring high-pressure steam with a fast response time. Unlike traditional fire-tube boilers, our water tube design circulates water inside the tubes while hot combustion gases flow around them. This configuration allows for safer operation at higher pressures and delivers “Instant Steam” within minutes.

Our range from 750 KG to 4000 KG/hr is the preferred choice for industrial processes that demand high efficiency in a compact, space-saving footprint.

Key Features & Advantages

- Rapid Steam Generation: Reaches full working pressure in just 3 to 6 minutes from a cold start, significantly reducing fuel wastage during startup cycles.

- High-Pressure Performance: Specifically engineered to handle high-pressure requirements (up to 21 kg/cm² or more), making it ideal for demanding industrial processes that fire-tube boilers cannot support.

- Maximum Safety: Features a “Water-in-Tube” design where water volume is divided into small-diameter tubes, eliminating the risk of catastrophic shell explosions and ensuring a safer workspace.

- Superior Efficiency: Achieves up to 90% to 92% thermal efficiency through a multi-pass design and high-velocity water circulation that optimizes heat absorption.

- Compact Footprint: The vertical, space-saving configuration requires up to 50% less floor area than traditional horizontal boilers, allowing for flexible installation in tight utility rooms.

- Robust Metallurgy: Constructed with high-grade ASTM A106 seamless tubes and boiler-quality plates to withstand extreme thermal stresses and ensure a service life of over 20 years.

- Automatic Control: Equipped with advanced PLC/PID controllers and modulating burners for precise steam pressure maintenance and fail-safe, unattended operation.

- Quick Load Response: Instantly reacts to fluctuating steam demands without pressure drops, ensuring your production line maintains consistent heat throughout the cycle.

Industrial Applications

Our 750 KG – 4000 KG range is currently powering:

-

Chemical & Pharma: For high-pressure reactor heating and sterilization.

-

Textiles: For dyeing and high-speed processing units.

-

Refineries: Where high-temperature steam is critical for distillation.

-

Food Processing: Ideal for large-scale pasteurization and cooking lines.

-

Plywood & Laminates: Providing the high-pressure steam required for presses.

Operating Range

- Capacity – 750 KG to 4000 KG

- Fuel- OIL, GAS, FO

- Pressure- 10.54 Kg/cm² to 21 Kg/cm²

Technical Specifications

| SPECIFICATION | unit | WS-600 | WS-750 | WS-1000 | WS-1500 | WS-2000 | WS-2500 | WS-3000 | WS-4000 | WS-5000 |

|---|---|---|---|---|---|---|---|---|---|---|

| General | ||||||||||

| Steam output from & at 100℃ | Kg/hr | 600 | 750 | 1000 | 1500 | 2000 | 2500 | 3000 | 4000 | 5000 |

| Working pressure | MPa | 0.98 | ||||||||

| Heat surface | M² | 4.9 | 9.8 | 18.6 | 29.4 | |||||

| Nos of passes | No’s | Three | Three | Three | Three | Three | Three | Three | Three | Three |

| No’s of furnace | No’s | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| Combustion control | 3 Position | PID Continuous | ||||||||

| Feed Water Control | 2 Position | PID Continuous | ||||||||

| Feed Water Temperature | ℃ | 15~100 | ||||||||

| Type of fuel: Natural gas, LPG | ||||||||||

| Gas supply pressure | Mbar | 300 | ||||||||

| Boiler efficiency | % | 90 | ||||||||

| Fuel consumption | NGm3N/h | 40.40 | 50.5 | 67.4 | 101.1 | 134.8 | 168.5 | 202.2 | 269.6 | 337.0 |

| LPGKg/hr | 32.7 | 40.9 | 54.5 | 81.7 | 109.0 | 136.3 | 163.4 | 218.0 | 272.6 | |

| Holding water quantity | L | 148 | 275 | 280 | 620 | 990 | ||||

| Dry weight | Kg | 1460 | 1560 | 2400 | 2500 | 2700 | 5000 | 7800 | ||

| Power supply | AC415V.50Hz.3 phase | |||||||||

| Power Capacity | ||||||||||

| Forced Draft Fan | KW | 2.2 | 5.5 | 7.5 | 11 | 15 | 22 | |||

| Feed water pump | KW | 0.75 | 1.5 | 2.2 | 3.0 | 4.0 | 5.5 | |||

| Control panel | KW | 0.2 | 0.5 | |||||||

| NOTE: In view of constant endeavors to improve our products, we reserve the right to alter or change above specifications without prior notice. | ||||||||||

Frequently Asked Questions

How does a Water Tube Boiler generate steam so quickly?

Because the total volume of water in the tubes is relatively small compared to the heating surface area, the water reaches boiling point almost instantly. Our units at indianboilers.com can generate steam in just 3 to 6 minutes.

What is "Natural Circulation" vs. "Forced Circulation"?

- Natural: Uses the density difference between cold water and hot steam to circulate water.

- Forced: Uses a high-pressure pump to drive water through the tubes, allowing for more compact designs and higher heat transfer rates.

Why is the Water Tube design considered safer?

The water is divided into many small-diameter tubes. If a tube fails, only a tiny amount of water is released. Unlike fire-tube boilers, there is no large central shell that can cause a catastrophic explosion.

What is the maximum pressure a Water Tube Boiler can handle?

Water tube boilers are the kings of high pressure. While fire-tube boilers usually top out at 17.5 kg/cm², our water tube models can easily be designed for 32 kg/cm² to 100 kg/cm² and beyond.

What is the typical efficiency of these boilers?

Our modern water tube boilers achieve 88% to 92% efficiency. Their design allows for the integration of advanced heat recovery systems like economizers and superheaters very effectively.

Can a Water Tube Boiler handle "Peak Load" fluctuations?

Yes. Due to the low water inventory and fast heat transfer, these boilers can ramp up steam production almost instantly when a machine starts, maintaining stable pressure across your plant.

Is the steam produced "Dry" or "Wet"?

Water tube boilers generally produce high-quality Dry Saturated Steam. Because they can be easily fitted with superheaters, they are the preferred choice for power generation and turbine operation.

Which industries benefit most from Water Tube Boilers?

- Power Plants: For driving turbines.

- Chemicals & Pharma: For high-pressure reactor heating.

- Textiles: For high-speed processing ranges.

- Refineries: Where high-temperature, high-pressure steam is mandatory.

What fuels can be used?

At indianboilers.com, our water tube boilers are multi-fuel compatible. They can run on Natural Gas, LPG, Diesel (HSD), or even biomass and waste heat depending on the furnace design.

Does a Water Tube Boiler require IBR approval?

Yes. Almost all industrial water tube boilers fall under IBR (Indian Boiler Regulations) due to their high pressure and capacity. We handle all the necessary IBR documentation and inspections for you.

How critical is water treatment for these boilers?

Extremely critical. Because the tubes are small, even a thin layer of scale (calcium) can cause a tube to overheat and burst. We recommend RO (Reverse Osmosis) or DM water with zero hardness.

How do you clean the outside of the tubes?

We install "Soot Blowers" or provide easy-access doors. Regular cleaning of the tube exteriors ensures that combustion soot doesn't insulate the tubes and drop your efficiency.

What are the common safety interlocks?

Our systems include Low Water Flow Switches, High-Pressure Cut-offs, Flame Sensors, and multiple Spring-Loaded Safety Valves.

What is the price of a 1 TPH (1000 KG) Water Tube Boiler?

For 2025, a 1 TPH IBR-certified water tube boiler at indianboilers.com typically ranges from ₹6 Lakh to ₹18 Lakh, depending on the pressure rating and burner type.

Why are Water Tube Boilers more expensive than Fire-Tube models?

The cost is higher due to the complex tube-bending process, the use of high-grade seamless pressure tubes, and the advanced automation required to manage the high-speed steam generation.

What is the price for a 3 TPH (3000 KG) Water Tube Boiler?

A 3 TPH high-pressure unit generally costs between ₹25 Lakh and ₹45 Lakh. The price varies significantly based on whether it is a vertical "Coil Type" or a large "Drum Type" system.

What is the typical ROI (Return on Investment)?

The ROI is usually achieved in 14 to 18 months. The savings come from lower fuel consumption (due to 90%+ efficiency) and reduced downtime during production peaks.

Does it require a certified boiler operator?

Yes, per Indian law, IBR-certified boilers must be operated by a qualified boiler attendant. However, our PLC-based automation reduces the human labor required for monitoring.

How do I get an official quote?

Visit indianboilers.com and provide your Steam Capacity (TPH) and Working Pressure. Our engineering team will provide a technical and commercial proposal within 24 hours.

Reviews

There are no reviews yet.