AQUAJET – Oil / Gas Fired Hot Water Boiler

High-Efficiency Packaged Hot Water Solutions for Industrial Excellence

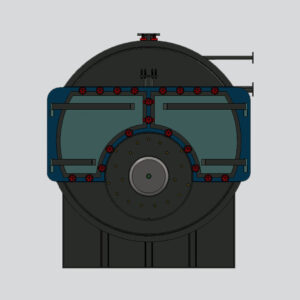

The AQUAJET series is a premier range of horizontal, three-pass, fully wet-back packaged hot water boilers. Engineered for maximum thermal efficiency and fuel flexibility, these units provide consistent hot water for various industrial processes without the need for high operating pressures. Whether your facility relies on light oils, heavy oils, or gaseous fuels, AQUAJET delivers reliable performance with minimal maintenance.

Oil / Gas Fired Hot Water Boilers are high-efficiency, fully automatic systems that use liquid or gaseous fuels to deliver consistent hot water for industrial processes and comfort heating applications. They are ideal for hotels, hospitals, commercial buildings, and factories that need dependable hot water with clean combustion and precise temperature control.

What is an oil / gas fired hot water boiler?

An oil / gas fired hot water boiler is a pressurised or atmospheric unit where burners fire LDO, HSD, furnace oil, LPG, CNG, or natural gas to heat water up to around 90 °C or higher as per design. The system includes a burner, combustion chamber, heat exchanger, water jacket, insulation, pumps, and control panel to maintain the desired outlet temperature and flow.

Key Features & Advantages

- High Efficiency: Achieves an overall efficiency of 85% to 90% (±2%), ensuring optimal fuel utilization and cost savings.

- Three-Pass Wet Back Design: Maximizes heat transfer while eliminating rear-end refractory maintenance and reducing radiation losses.

- Multi-Fuel Versatility: Seamlessly operates on Diesel, LPG, Natural Gas (NG), PNG, Furnace Oil (FO), and LDO.

- Flexible Temperature Range: Capable of delivering hot water up to 90°C in non-pressurized systems and up to 160°C in pressurized configurations.

- User-Friendly & Rugged: Built with high-grade materials and simple controls, requiring very little operational intervention.

- Compact & Packaged: Designed as a plug-and-play unit for quick installation and smaller footprint.

Benefits for users

Oil / gas fired hot water boilers provide quick start-up, compact footprint, and clean, low-particulate combustion compared to solid-fuel systems. High efficiency and automatic control help reduce specific fuel consumption, lower operating costs, and support consistent product quality in temperature-sensitive processes.

Operating Range

- Capacity – 0.1 million kcal/hr to 2.0 million kcal/hr

- Fuel- Heavy oils, light oils and gases

- Temperature- Up to 90°C without pressure and with pressure up to 160 °C

Technical Specifications

| Specification | Unit | AQJ-10 | AQJ-20 | AQJ-30 | AQJ-40 | AQJ-50 | AQJ-60 | AQJ-80 | AQJ-100 | AQJ-150 | AQJ-200 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| General | |||||||||||

| Maximum heat output | M. Kcal/hr | 0.1 | 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.8 | 1.0 | 1.5 | 2.0 |

| Maximum working temperature | °C | 95/150 | 95/150 | 95/150 | 95/150 | 95/150 | 95/150 | 95/150 | 95/150 | 95/150 | 95/150 |

| Hot water Rise temperature | °C | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 |

| Hot water Inlet/ Outlet | MM | 40 | 50 | 80 | 80 | 100 | 100 | 125 | 150 | 150 | 200 |

| Heating surface area of heater | M² | 6 | 12 | 18 | 24 | 30 | 36 | 54 | 60 | 90 | 120 |

| Burner | Pressure jet Monoblock Burner | ||||||||||

| Type of Fuel | Fuel | DIESEL, LPG, NG., PNG, FO,LDO | |||||||||

| Boiler Efficiency | |||||||||||

| On Gas | % | 90 +/-2 | 90 +/-2 | 90 +/-2 | 90 +/-2 | 90 +/-2 | 90 +/-2 | 90 +/-2 | 90 +/-2 | 90 +/-2 | 90 +/-2 |

| On Oil | % | 88 +/-2 | 88 +/-2 | 88 +/-2 | 88 +/-2 | 88 +/-2 | 88 +/-2 | 88 +/-2 | 88 +/-2 | 88 +/-2 | 88 +/-2 |

| Fuel Consumption | |||||||||||

| Diesel (10500) | Kg/hr | 11 | 22 | 32 | 43 | 54 | 65 | 87 | 108 | 162 | 216 |

| Furnace Oil (9600) | Kg/hr | 12 | 24 | 36 | 47 | 59 | 71 | 95 | 118 | 178 | 237 |

| LDO (10200) | Kg/hr | 11 | 22 | 33 | 45 | 56 | 67 | 89 | 111 | 167 | 223 |

| LPG (11000) | Kg/hr | 10 | 20 | 30 | 40 | 51 | 61 | 81 | 101 | 152 | 202 |

| Natural gas(8900) | M³/hr | 12 | 25 | 37 | 50 | 62 | 75 | 100 | 125 | 187 | 250 |

| Electrical Load | |||||||||||

| Circulation Water Pump | H.P. | 3.00 | 5.00 | 7.50 | 10.00 | 10.00 | 12.50 | 15.00 | 20.00 | 25.00 | 30.00 |

| Burner Blower (oil) | H.P. | 0.37 | 0.50 | 0.50 | 0.90 | 1.10 | 1.10 | 3.00 | 3.00 | 5.5 | 7.5 |

| Fuel Pump | H.P. | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 1.1 | 1.1 |

| Total Electric Load | H.P. | 3.37 | 5.50 | 8.00 | 10.90 | 11.10 | 13.60 | 18.00 | 23.00 | 31.60 | 38.60 |

| NOTE: In view of constant endeavors to improve our products, we reserve the right to alter or change above specifications without prior notice. | |||||||||||

Why Choose the AQUAJET Hot Water Boiler?

The AQUAJET is specifically designed for industries that need high-temperature water for processes like washing, sterilization, or climate control without the complexities of steam systems. Its horizontal design and robust monoblock burner technology from world-renowned brands ensure stability and longevity.

Common Applications:

- Hospitality (Hotels & Hospitals)

- Food & Dairy Processing

- Chemical & Textile Industries

- Centralized Heating Systems

Frequently Asked Questions

How does it differ from a Steam Boiler?

A hot water boiler heats water without changing its state to vapor. Because it operates at lower pressures and temperatures, it is generally easier to maintain, requires no IBR certification (in most cases), and has lower heat radiation losses.

Which fuels can be used in the VTFH/HTFH series?

Our units are highly versatile and can be equipped with burners for:

- Liquid Fuels: HSD (Diesel), LDO, or Furnace Oil.

- Gaseous Fuels: Natural Gas (PNG), LPG, or Propane.

- Dual-Fuel: Burners that can switch between oil and gas.

Why choose Oil/Gas over Biomass for hot water?

Oil/Gas boilers are much cleaner, more compact, and offer fully automatic operation. They don't require fuel storage yards, ash handling systems, or manual labor for feeding, making them ideal for urban or space-constrained areas.

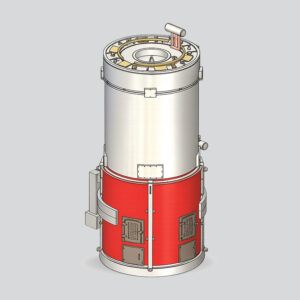

What is the difference between Vertical (VTFH) and Horizontal (HTFH) models?

- Vertical: Best for small-to-medium capacities where floor space is limited.

- Horizontal: Preferred for high-capacity industrial requirements as they offer easier access for tube cleaning and maintenance.

What is the typical thermal efficiency of these units?

At indianboilers.com, our oil/gas fired hot water boilers achieve an efficiency of 88% to 92%. Efficiency can be further improved by adding a waste heat recovery unit.

What is the maximum water temperature available?

Standard units go up to 90°C – 95°C. For specialized applications requiring "Pressurized Hot Water" (up to 140°C), we offer custom-engineered IBR-certified high-pressure models.

What capacities are available?

Our range starts from small 50,000 kcal/hr units up to large industrial systems of 5,000,000 kcal/hr.

How is the water temperature controlled?

We use high-precision Digital PID Controllers or PLC systems that modulate the burner. The burner automatically fires or shuts down based on the set-point temperature, ensuring consistent heat and fuel savings.

Do I need a circulating pump?

Yes. To ensure uniform heating and prevent localized boiling, a centrifugal pump is used to circulate water through the boiler and the process heat exchangers.

Which industries benefit most from these boilers?

- Hospitality: Centralized hot water for hotels and laundries.

- Healthcare: Sterilization and HVAC heating in hospitals.

- Food & Dairy: Pasteurization, CIP (Clean-In-Place), and washing.

- Textiles: For dyeing and finishing processes requiring moderate heat.

Can it be used for central space heating?

Absolutely. It is the most efficient way to provide centralized heating for large commercial complexes, worker colonies, or industrial warehouses in cold climates.

Is IBR certification mandatory?

Hot water boilers operating below 100°C are generally Non-IBR. This is a major advantage as it eliminates the need for annual government inspections and the requirement of a certified boiler attendant.

What safety features are included?

- Flame Safeguard: Shuts off fuel if no flame is detected.

- Over-Temperature Cut-off: Prevents the water from turning into steam.

- Low Water Flow Switch: Protects the boiler tubes from overheating if the pump fails.

How much maintenance is required?

Maintenance is minimal. It involves a monthly burner service (cleaning the nozzle and filters) and a periodic check of the electrical terminals. Since the fuels are clean, there is very little soot buildup.

Does hard water affect the boiler?

Yes. Scaling is the biggest enemy of any boiler. Using a Water Softener is mandatory to prevent calcium buildup, which reduces heat transfer and increases fuel consumption.

What is the price of an Oil / Gas Fired Hot Water Boiler?

Pricing is capacity-dependent. Estimated 2025 rates at indianboilers.com are:

- Small (1 Lac – 3 Lac kcal/hr): ₹600,000.

- Medium (5 Lac – 10 Lac kcal/hr): ₹7,00,000 – ₹15,00,000.

- High Capacity (20 Lac+ kcal/hr): ₹25,00,000+.

- Prices vary based on the choice of burner brand (Riello, Bentone, etc.) and automation level.

What factors influence the final quote?

The kcal/hr capacity, the type of fuel (Oil vs. Gas vs. Dual), and the Control System (Standard vs. PLC-based) are the primary cost drivers.

What is the typical ROI period?

While fuel costs are higher than biomass, the ROI comes from zero labor costs, minimal maintenance, and compact size. Most businesses see a full ROI within 12 to 18 months due to high operational uptime.

How can I get an official quote for my project?

Visit indianboilers.com and use our "Request a Quote" form. Please specify your required water temperature and flow rate (LPH) for a detailed technical and commercial proposal.

Jagat Apate –

We chose the dual-fuel (Oil/Gas) model for its versatility, and it has not disappointed. It switches seamlessly and provides instant hot water for our process needs. The build quality is top-notch, and the installation team was very professional and knowledgeable. If you need a reliable industrial boiler in India, this is the place to go.