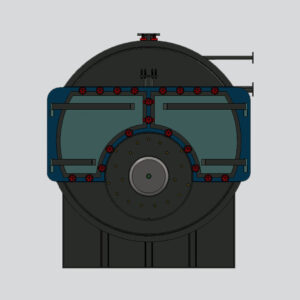

Dual Firing Wood Semi-Industrial Boilers

Flexibility | Power | Sustainable Industrial Heating

At IndianBoilers.com, our Dual Firing Series provides the ultimate fuel security for your production line. These semi-industrial boilers are specifically designed to operate primarily on Wood/Biomass, with the secondary capability to fire Gas or Oil.

This “Hybrid” approach allows you to take advantage of low-cost timber and wood waste while having a backup fuel source ready at the flip of a switch, ensuring your factory never stops due to fuel shortages.

Key Features & Performance

- True Fuel Flexibility: Seamlessly switch between Firewood/Briquettes and Gas/Diesel depending on price and availability.

- Hybrid Furnace Design: Features a large-volume primary furnace for efficient wood combustion and a secondary combustion chamber optimized for high-efficiency burners.

- High Thermal Efficiency: Designed with a 3-pass heat exchanger that achieves 75%–80% efficiency on wood and up to 88% on gas/oil.

- Rugged Grate System: Equipped with heavy-duty cast-iron fire bars designed to handle the high temperatures of wood-fire without warping.

- Large Fire Door: Extra-wide feeding door to accommodate larger logs, reducing the labor required for fuel preparation.

- Low Carbon Footprint: Utilizing wood as a primary fuel makes your steam generation carbon-neutral while maintaining industrial-scale output.

Operating Range

- Capacity: 100 Kg/hr to 500 Kg/hr

- Fuel: Coal, Wood, Gas, Oil, or Electrical Power

- Pressure: 7.00 Kg/cm2

Core Industry Applications

These dual-fired boilers are the backbone of industries with access to wood waste:

- Plywood & Furniture: Utilizing internal wood waste to power steam presses.

- Food Processing: Reliable steam for boiling, drying, and pasteurization using agricultural waste.

- Textile Dyeing: High-volume steam requirements met with low-cost biomass fuel.

- Chemical Plants: Consistent heat for reactors with a gas-fired backup for precision control.

- Agro-Industries: Utilizing husks, shells, and wood for drying operations.

Advantages

- Safety Interlocks: Equipped with water level controllers, pressure switches, and safety valves that work across both firing modes.

- Simplified Conversion: Our dual-firing units come with a pre-installed burner mounting plate, making the transition from wood to gas/oil fast and easy.

- Advanced Pollution Control: Can be integrated with Cyclones or Multi-Cyclone Dust Collectors to ensure clean stack emissions that meet local PCB norms.

- Ahmedabad Heritage: Robustly manufactured to handle the tough operating conditions of the Indian industrial landscape.

Technical Specifications

| Model | HX-series | VX-series | JX-Series | |

|---|---|---|---|---|

| Specification | Unit | HX-04 | VX-04 | JX-05 |

| General | ||||

| Steam Output (at 100°C) | Kg/hr | 400 | 400 | 500 |

| Working Pressure | Kg/cm² | 7.00 | 7.00 | 7.00 |

| Steam Temperature | °C | 164 | 164 | 164 |

| No. of Passes | Qty | 2 | 1 | 2 |

| No. of Furnaces | Qty | 1 | 1 | 1 |

| Steam Outlet | mm | 25 | 25 | 25 |

| HTA | m² | 15 | 16 | 13 |

| Type of Fuel | Fuel | Solid | Solid | Oil/Gas |

| Boiler Efficiency | ||||

| On Woodlog & Briquette | % | 70 ± 2 | 70 ± 2 | — |

| On Oil and Gas | % | — | — | 85 ± 2 |

| Fuel Consumption | ||||

| WoodLog (3500) | Kg/hr | 88 | 88 | 0 |

| Briquette (4000) | Kg/hr | 77 | 77 | 0 |

| N.G. (9600) | m³/hr | 0 | 0 | 33 |

| Diesel (10500) | Kg/hr | 0 | 0 | 30 |

| Electrical Load | ||||

| Feed Water Pump | H.P. | 2.00 | 2.00 | 2.00 |

| I.D. Fan (without BF) | H.P. | 3.00 | 0.00 | 0.00 |

| F.D. Fan | H.P. | 0.00 | 0.00 | 2.00 |

| Total Electric Load | H.P. | 5.00 | 2.00 | 4.00 |

| NOTE: In view of constant endeavors to improve our products, we reserve the right to alter or change above specifications without prior notice. | ||||

Frequently Asked Questions

Can I use sawdust or wood chips?

Yes, though these fuels burn better with our specialized forced-draft (FD) fan systems to ensure complete combustion.

Is the maintenance higher for dual-firing boilers?

While wood firing requires periodic ash removal, the overall maintenance is low due to our high-quality refractory and heavy-duty shell design.

Does this require a tall chimney?

Yes, wood-firing requires a natural or induced draft, usually necessitating a chimney of 20–30 meters depending on capacity.

Are these boilers IBR certified?

We manufacture both IBR and Non-IBR versions depending on your steam capacity and local regulatory requirements.

Reviews

There are no reviews yet.