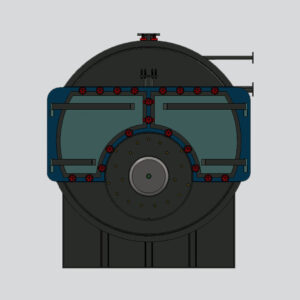

6 Ton Diesel Fired Steam Boiler (6000 Kg/hr)

High-Capacity Performance | Precision German Combustion | Rapid Steam Generation

At IndianBoilers.com, our 6 Ton Diesel Fired Steam Boilers (HSD/LDO) are designed for large-scale industrial plants that require massive steam volumes with the precision control of liquid fuel. Unlike solid-fuel boilers, our 6 TPH diesel units offer instant response to load fluctuations, making them the preferred choice for sophisticated manufacturing processes.

Manufactured at our Ahmedabad facility, the STEAMJET SJ-60 combines heavy-duty metallurgy with advanced automation to deliver an industry-leading 95% thermal efficiency.

Key Features & Performance

- 95% Maximum Efficiency: Achieves peak thermal performance when integrated with our custom-engineered sensible heat recovery units.

- ELCO-Germany Burner Technology: Equipped with high-performance dual-block burners from ELCO-Germany, ensuring perfect atomization and complete fuel combustion.

- Plug-and-Play Skid: Even at a 6 TPH capacity, our units are available in a 100% skid-mounted configuration, significantly reducing on-site installation time and civil costs.

- High Dryness Fraction: Optimized internal separators ensure the delivery of high-quality dry steam, maximizing the heat energy transferred to your process.

- 3-Element Control System: Standard on our 6 Ton models, this system provides synchronized monitoring of water level, steam flow, and feedwater flow for ultimate safety.

- Robust Shell Design: Features a large water-holding capacity and high steam-space volume to handle heavy load surges without pressure drops.

- Low Stack Temperatures: Advanced 3-pass smoke tube design ensures that maximum heat is captured before flue gases exit the system.

Operating Range

Our 6 Ton Diesel series is built for 24/7 industrial endurance.

- 1. Capacity: 6.0 TPH (6000 Kg/hr) — Scaling available from 0.5 TPH to 15 TPH.

- 2. Fuel Options: High-Speed Diesel (HSD), Light Diesel Oil (LDO), and Multi-fuel (Oil/Gas) configurations.

- 3. Working Pressure: Precision designs for pressures between 10.54 Kg/cm2 and 21 Kg/cm2.

- 4. Metallurgy: Constructed using IBR-approved SA 515/516 Gr. 70 boiler-quality plates for maximum longevity.

Core Industry Applications

The 6 Ton Diesel Fired Boiler is the powerhouse for:

- Large Textile Mills: Continuous high-pressure steam for processing, dyeing, and printing.

- Edible Oil Refineries: Reliable heat for neutralization, bleaching, and deodorization.

- Chemical & Agro-Chemicals: Driving large-scale jacketed reactors and distillation plants.

- Pulp & Paper: Steady steam supply for drying cylinders and pulp processing.

Advantages

By choosing IndianBoilers.com, you invest in premium quality and local support:

- Hassle-Free Maintenance: Features a hinged front and rear smoke chamber, allowing for easy tube inspection and cleaning without heavy dismantling.

- Environmental Compliance: High-efficiency combustion ensures that emissions remain well within GPCB and central pollution board limits.

- Local Expertise: Based in Ahmedabad, our technical team handles everything from IBR registration to annual maintenance and genuine ELCO burner spares.

Technical Specifications

| Specification | Unit | SJ-05 | SJ-10 | SJ-15 | SJ-20 | SJ-30 | SJ-40 | SJ-50 | SJ-60 | SJ-80 | SJ-100 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| General | |||||||||||

| Steam Output From & at 100°C | Kg/hr | 500 | 1000 | 1500 | 2000 | 3000 | 4000 | 5000 | 6000 | 8000 | 10000 |

| Working Pressure | Kg/CM² | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 |

| Steam Temprature | °C | 183 | 183 | 183 | 183 | 183 | 183 | 183 | 183 | 184 | 185 |

| No’s Passes | No’s | Three | Three | Three | Three | Three | Three | Three | Three | Three | Three |

| No’s of Furnace | No’s | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| Steam Outlet | MM | 40 | 50 | 80 | 80 | 100 | 100 | 125 | 150 | 150 | 200 |

| HTA | M² | 15 | 30 | 45 | 60 | 90 | 120 | 150 | 180 | 240 | 300 |

| Burner: Pressure jet Monoblock Burner | |||||||||||

| Type of Fuel: Diesel, LPG, NG, PNG, FO, LDO | |||||||||||

| Boilers Efficiency | |||||||||||

| On Gas | % | 90 +/-2 | 90 +/-2 | 90 +/-2 | 90 +/-2 | 90 +/-2 | 90 +/-2 | 90 +/-2 | 90 +/-2 | 90 +/-2 | 90 +/-2 |

| On Oil | % | 88 +/-2 | 88 +/-2 | 88 +/-2 | 88 +/-2 | 88 +/-2 | 88 +/-2 | 88 +/-2 | 88 +/-2 | 88 +/-2 | 88 +/-2 |

| Fuel Consumption | |||||||||||

| Diesel (10500) | Kg/hr | 29 | 58 | 88 | 117 | 175 | 234 | 292 | 351 | 468 | 584 |

| Furnace Oil (9600) | Kg/hr | 32 | 64 | 96 | 128 | 192 | 256 | 320 | 384 | 511 | 639 |

| LDO (10200) | Kg/hr | 30 | 60 | 90 | 120 | 180 | 241 | 301 | 361 | 481 | 602 |

| LPG (11000) | Kg/hr | 30 | 60 | 90 | 120 | 180 | 241 | 301 | 361 | 481 | 602 |

| Natural gas(8900) | M³/hr | 34 | 67 | 101 | 135 | 202 | 270 | 337 | 404 | 539 | 674 |

| Electrical Load | |||||||||||

| Feed Water Pump | H.P. | 2.00 | 2.00 | 3.00 | 3.00 | 4.00 | 4.00 | 6.00 | 7.50 | 10.00 | 15.00 |

| Burner Blower (oil) | H.P. | 0.37 | 1.10 | 3.00 | 3.00 | 5.50 | 7.50 | 7.50 | 11.00 | 18.5 | 18.5 |

| Fuel Pump | H.P. | * | * | * | * | 1.10 | 1.10 | 1.10 | 1.50 | 3.0 | 3.0 |

| Total Electric Load | H.P. | 2.37 | 3.10 | 6.00 | 6.00 | 10.60 | 12.60 | 14.60 | 20.00 | 31.50 | 36.50 |

| NOTE: In view of constant endeavors to improve our products, we reserve the right to alter or change above specifications without prior notice. | |||||||||||

Frequently Asked Questions

What is the hourly fuel consumption for a 6 Ton Diesel boiler?

At full load, the boiler consumes approximately 380 to 410 Liters of HSD (Diesel) per hour, depending on the feedwater temperature and burner efficiency.

What is the thermal efficiency of the 6 TPH unit?

Our Diesel-fired boilers achieve a thermal efficiency of 88% to 90%, which can be increased to 95% with the integration of an Indian Boilers' sensible heat recovery unit (Economizer).

Can this boiler run on fuels other than Diesel?

Yes. By installing a Multi-Fuel Burner, the unit can be configured to run on LDO (Light Diesel Oil) or even converted to PNG/LPG if gas becomes available at your site.

How does the boiler handle high-volume steam demand?

The 6 Ton unit features a Large Shell Diameter and a high water-holding capacity, which acts as a thermal buffer to maintain stable pressure during sudden industrial load spikes.

Is this 6 Ton boiler IBR compliant?

Yes, all our 6 TPH units are fully IBR (Indian Boiler Regulations) certified, ensuring they meet the highest national safety and quality standards.

What is the advantage of the 3-Pass Wet Back design?

This design forces hot gases to pass through the water three times for maximum heat absorption. The "Wet Back" feature replaces fragile rear refractories with water-cooled walls, reducing maintenance and increasing heat surface area.

What grade of steel is used for construction?

The boiler shell and tube sheets are manufactured from IBR-approved SA 515/516 Gr. 70 boiler-quality plates, and the tubes are high-grade BS 3059 / SA 192 seamless carbon steel.

What is the standard working pressure?

Standard designs are available for 10.54 Kg/cm² and 17.5 Kg/cm². Custom high-pressure units can be engineered upon request.

What burner technology is utilized?

We equip the 6 Ton range with premium Modulating Burners from brands like ELCO (Germany) or Riello (Italy) for precise fuel metering and high turndown ratios.

Is the 6 Ton boiler operation fully automated?

Yes, it features a sophisticated PLC-based HMI Control Panel that automates the firing sequence, water level regulation, and safety shutdowns.

What safety interlocks are provided?

Standard safety features include dual IBR safety valves, low water cut-off (LWCO), flame failure detection, air pressure switches, and high steam pressure cut-offs.

Can this boiler be integrated into a SCADA system?

Yes, our control panels are equipped for BMS/SCADA integration, allowing for remote monitoring and data logging of all boiler parameters.

Does it include an automatic blowdown system?

We offer an optional Automatic TDS-based Blowdown system to maintain water quality and prevent scale buildup without manual intervention.

What is the electrical connected load?

For a 6 TPH unit, the total connected load (including the large burner blower and high-capacity feed pumps) is approximately 25 HP to 30 HP.

What is the footprint of a 6 Ton Diesel boiler?

While it is a high-capacity unit, our horizontal design is optimized to be as compact as possible. We provide a detailed general arrangement (GA) drawing to assist in your boiler house layout.

Is it available as a skid-mounted package?

Yes, for faster installation, we provide complete skid-mounted solutions where the boiler and primary accessories are pre-installed on a heavy-duty steel frame.

How easy is it to clean the internal tubes?

The boiler features large hinged doors on both the front and rear, providing complete access for mechanical tube cleaning and IBR inspections.

What kind of chimney is required for a 6 Ton unit?

As per environmental norms, a 30-meter high chimney is typically required for a 6 TPH Diesel boiler to ensure proper emission dispersion.

Do you provide maintenance services in Ahmedabad?

Yes, our Ahmedabad-based headquarters provides nationwide support, including genuine spare parts, annual maintenance contracts (AMC), and IBR renewal assistance.

Reviews

There are no reviews yet.