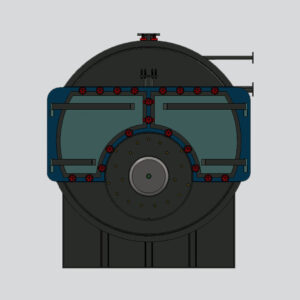

500 Kg/hr LDO Fired Steam Boiler

Instant Steam Generation | Compact Design | Precision Combustion

At IndianBoilers.com, our 500 Kg/hr LDO Fired Steam Boilers are engineered for industries that require high-quality steam on demand with minimal floor space. By utilizing Light Diesel Oil (LDO), these boilers offer a cleaner combustion profile and higher thermal efficiency compared to solid-fuel alternatives, making them ideal for urban industrial zones and precision-heavy processes.

Manufactured at our Ahmedabad facility, this 0.5 TPH unit combines robust metallurgy with advanced burner technology to deliver consistent performance and long-term reliability.

Key Features & Performance

- Rapid Steam Generation: Features a high-efficiency coil or shell design that delivers full steam pressure within just 4 to 6 minutes of a cold start.

- High Thermal Efficiency: Achieves 88% efficiency (on NCV) by utilizing an integrated heat recovery system and a precision-tuned LDO burner.

- Reverse Flame Technology: The furnace design ensures that the flame travels back through the combustion chamber, maximizing heat absorption and ensuring zero fuel wastage.

- Precision Burner Control: Equipped with a fully automatic burner that modulates fuel and air ratios for perfect combustion and lower emission levels.

- Space-Saving Footprint: The compact, vertical or horizontal skid-mounted design is perfect for facilities with limited space.

- Advanced Safety Interlocks: Fully compliant with IBR (Indian Boiler Regulations), featuring automatic low-water cut-offs, over-pressure sensors, and flame failure protection.

- Minimum Maintenance: Features a unique coil/tube design that reduces scaling and allows for easy internal inspection and cleaning.

Operating Range & Specifications

Our 500 Kg/hr LDO series is part of our “Quick-Steam” line, built for precision and speed.

- 1. Capacity: 500 Kg/hr (0.5 TPH) — Available in our LDO range from 200 Kg/hr to 5.0 TPH.

- 2. Fuel: Light Diesel Oil (LDO) / High-Speed Diesel (HSD), Natural Gas, LPG.

- 3. Working Pressure: Standard designs from 10.54 Kg/cm2 to 17.5 Kg/cm2.

- 4. Automation: Fully automatic “Press-to-Start” operation with PLC-based monitoring.

Core Industry Applications

The 500 Kg/hr LDO Boiler is the “Gold Standard” for:

- Pharma & Healthcare: For sterilization, autoclaves, and cleanroom humidity control.

- Hotels & Hospitals: Centralized laundry, kitchen steam, and hot water systems.

- Ready-to-Eat Food: Precision heating for retorts, kettles, and pasteurizers.

- Garment Finishing: Providing high-quality dry steam for industrial steam irons and tunnels.

- Dairies: Ideal for small to medium scale pasteurization and milk processing units.

Advantages

By choosing IndianBoilers.com, you invest in premium quality and local support:

- High-Grade Components: We use world-class pumps and burner components to ensure your boiler runs 24/7 without interruption.

- Powder-Coated Durability: All control panels and enclosures are powder-coated for superior corrosion resistance in industrial environments.

- Instant Technical Support: Based in Ahmedabad, our service team is always available for immediate on-site assistance and spare parts supply.

Technical Specifications

| Specification | Unit | SJ-05 | SJ-10 | SJ-15 | SJ-20 | SJ-30 | SJ-40 | SJ-50 | SJ-60 | SJ-80 | SJ-100 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| General | |||||||||||

| Steam Output From & at 100°C | Kg/hr | 500 | 1000 | 1500 | 2000 | 3000 | 4000 | 5000 | 6000 | 8000 | 10000 |

| Working Pressure | Kg/CM² | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 |

| Steam Temprature | °C | 183 | 183 | 183 | 183 | 183 | 183 | 183 | 183 | 184 | 185 |

| No’s Passes | No’s | Three | Three | Three | Three | Three | Three | Three | Three | Three | Three |

| No’s of Furnace | No’s | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| Steam Outlet | MM | 40 | 50 | 80 | 80 | 100 | 100 | 125 | 150 | 150 | 200 |

| HTA | M² | 15 | 30 | 45 | 60 | 90 | 120 | 150 | 180 | 240 | 300 |

| Burner: Pressure jet Monoblock Burner | |||||||||||

| Type of Fuel: Diesel, LPG, NG, PNG, FO, LDO | |||||||||||

| Boilers Efficiency | |||||||||||

| On Gas | % | 90 +/-2 | 90 +/-2 | 90 +/-2 | 90 +/-2 | 90 +/-2 | 90 +/-2 | 90 +/-2 | 90 +/-2 | 90 +/-2 | 90 +/-2 |

| On Oil | % | 88 +/-2 | 88 +/-2 | 88 +/-2 | 88 +/-2 | 88 +/-2 | 88 +/-2 | 88 +/-2 | 88 +/-2 | 88 +/-2 | 88 +/-2 |

| Fuel Consumption | |||||||||||

| Diesel (10500) | Kg/hr | 29 | 58 | 88 | 117 | 175 | 234 | 292 | 351 | 468 | 584 |

| Furnace Oil (9600) | Kg/hr | 32 | 64 | 96 | 128 | 192 | 256 | 320 | 384 | 511 | 639 |

| LDO (10200) | Kg/hr | 30 | 60 | 90 | 120 | 180 | 241 | 301 | 361 | 481 | 602 |

| LPG (11000) | Kg/hr | 30 | 60 | 90 | 120 | 180 | 241 | 301 | 361 | 481 | 602 |

| Natural gas(8900) | M³/hr | 34 | 67 | 101 | 135 | 202 | 270 | 337 | 404 | 539 | 674 |

| Electrical Load | |||||||||||

| Feed Water Pump | H.P. | 2.00 | 2.00 | 3.00 | 3.00 | 4.00 | 4.00 | 6.00 | 7.50 | 10.00 | 15.00 |

| Burner Blower (oil) | H.P. | 0.37 | 1.10 | 3.00 | 3.00 | 5.50 | 7.50 | 7.50 | 11.00 | 18.5 | 18.5 |

| Fuel Pump | H.P. | * | * | * | * | 1.10 | 1.10 | 1.10 | 1.50 | 3.0 | 3.0 |

| Total Electric Load | H.P. | 2.37 | 3.10 | 6.00 | 6.00 | 10.60 | 12.60 | 14.60 | 20.00 | 31.50 | 36.50 |

| NOTE: In view of constant endeavors to improve our products, we reserve the right to alter or change above specifications without prior notice. | |||||||||||

Frequently Asked Questions

What is the difference between LDO and HSD (Diesel) for this boiler?

LDO is a lower-grade fuel compared to HSD and is often more economical for industrial heating. This boiler is specifically designed with a burner that can handle the slightly higher viscosity of LDO.

What is the thermal efficiency of this 500 Kg model?

This model achieves 88% thermal efficiency, which can be pushed to 92%+ with the installation of a compact economizer.

Does LDO require pre-heating like Furnace Oil?

No, LDO typically flows freely at room temperature, so a pre-heater is generally not required, simplifying the system compared to FO boilers.

How does the boiler ensure fuel savings?

By using a high-precision monoblock burner, the boiler maintains a perfect air-to-fuel ratio, preventing unburnt fuel waste.

What is the exact steam output?

The boiler provides a rated capacity of 500 Kg of steam per hour.

Is this boiler IBR or Non-IBR?

We offer the 500 Kg/hr model in both IBR and Non-IBR versions. For many small-scale units, our Non-IBR "Coil Type" is popular due to fewer regulatory requirements.

What is the standard working pressure?

The standard design pressure is 7 Kg/cm² to 10.54 Kg/cm².

What is the advantage of a "Vertical Coil Type" design?

It allows for instant steam generation (within 3–5 minutes) and has a very small footprint, making it ideal for factories with limited space.

What burner brand is used?

We use premium Riello or ELCO burners to ensure reliable ignition and low maintenance.

Is the 500 Kg LDO boiler fully automatic?

Yes. It features a "Push-Button" start with an automatic control panel that manages the firing sequence and water feeding.

How long does it take to get steam from a cold start?

Our coil-type design provides full pressure steam in just 3 to 5 minutes, which is much faster than traditional shell-type boilers.

What safety features are included?

The boiler includes a high-pressure cut-off, flame failure sensor, low water flow switch, and a spring-loaded safety valve.

What is the electrical load for this unit?

The total connected load is approximately 2 HP to 3 HP, covering the burner motor and the high-pressure feedwater pump.

Can it be operated by a non-technical person?

While it is fully automatic, we recommend a basic training session (provided by us) for your operator to handle daily checks and blowdown procedures.

Is this 500 Kg boiler skid-mounted?

Yes, it is a compact, skid-mounted unit. The boiler, pump, and panel come as a single package for easy "Plug-and-Play" installation.

What kind of water treatment is required?

To prevent coil scaling, a Water Softener is mandatory to keep water hardness below 5 ppm.

How do I clean the coil?

The coil can be cleaned through a process called "Descaling" using a chemical pump. We provide the necessary ports and instructions for this procedure.

What is the footprint (space requirement)?

The 500 Kg vertical model is very compact, typically requiring only about 4 feet x 4 feet of floor space (excluding the softener).

Do you provide service support in Ahmedabad?

Yes, our Ahmedabad-based service team provides 24/7 support, genuine spares, and annual maintenance contracts for all LDO fired units.

Reviews

There are no reviews yet.