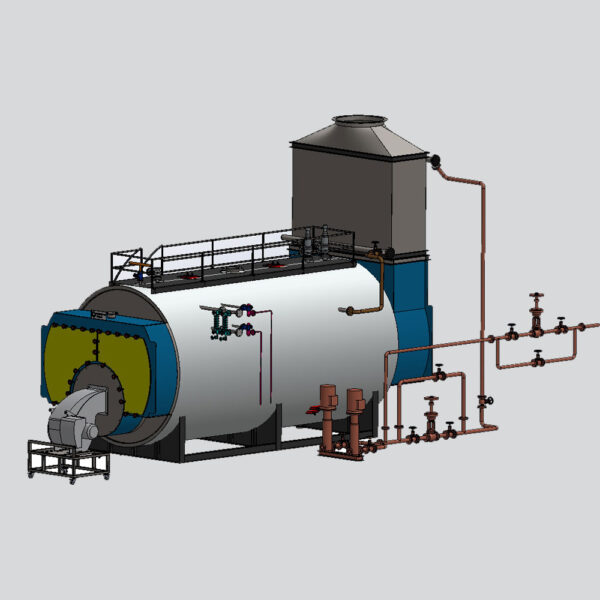

5 Ton PNG / LPG Fired Steam Boiler (5000 Kg/hr)

High-Capacity Clean Energy | 95% Thermal Efficiency | Fully Automated Industrial Steam

At IndianBoilers.com, our 5 Ton PNG (Piped Natural Gas) and LPG Fired Steam Boilers are the ultimate solution for large-scale manufacturing plants requiring reliable, high-pressure steam. By utilizing gaseous fuels, these boilers eliminate the logistics of fuel storage and ash handling, offering a streamlined, automated, and environmentally superior steam plant.

Manufactured at our Ahmedabad facility, the STEAMJET SJ-50 series is designed for continuous duty, featuring German-engineered combustion systems and intelligent monitoring.

Key Features & Performance

- Unmatched Efficiency: Delivers an overall thermal efficiency of up to 95% when integrated with our advanced sensible heat recovery units.

- German Engineering: Equipped with world-renowned mono-block or dual-block burners from ELCO-Germany, ensuring perfect combustion and low NOx emissions.

- Large Water Holding Capacity: Built with a high-volume shell to handle massive load fluctuations and sudden steam surges common in large-scale production.

- High Dryness Fraction: Optimized steam separators ensure high dryness fraction steam, delivering more enthalpy (heat energy) to your process equipment.

- 3-Element Control System: Comes standard with advanced monitoring for water level, steam flow, and feedwater flow to ensure maximum safety and efficiency.

- Plug-and-Play Availability: Even at 5 TPH, our units are designed as 100% skid-mounted systems for rapid installation and reduced civil engineering costs.

- Smart Monitoring Panels: Features high-tech PLC panels for real-time data logging and remote boiler monitoring.

Operating Range

The 5 Ton Gas series is built for heavy-duty industrial performance and longevity.

- 1. Capacity: 5.0 TPH (5000 Kg/hr) — Part of our high-capacity series up to 10 TPH.

- 2. Fuel Options: PNG (Natural Gas), LPG, Propane, and Multi-fuel (Gas/Oil) options.

- 3. Working Pressure: Standard designs accommodate pressures from 10.54 Kg/cm2 to 21 Kg/cm2.

- 4. Compliance: Fully IBR (Indian Boiler Regulations) certified using high-grade SA 515/516 boiler quality steel.

Core Industry Applications

The 5 Ton PNG/LPG Boiler is the workhorse for:

- Large Beverage Plants: High-volume steam for bottling lines and sterilization.

- Textile Megaplants: Continuous steam for dyeing, printing, and stenter operations.

- Bulk Drug Pharma: Precise temperature control for large-scale chemical reactors.

- Distilleries: Driving distillation columns with steady, high-pressure steam.

Advantages

By choosing IndianBoilers.com, you partner with Gujarat’s leading boiler manufacturer:

- Low Stack Temperature: Our 3-pass design captures maximum heat within the boiler, ensuring minimal energy loss through the chimney.

- Environmental Compliance: Easily meets and exceeds GPCB and central pollution board norms for clean air.

- Local Expertise & Spares: Based in Ahmedabad, we maintain a full inventory of ELCO burner spares and provide 24/7 technical support for our high-capacity units.

Technical Specifications

| Specification | Unit | SJ-05 | SJ-10 | SJ-15 | SJ-20 | SJ-30 | SJ-40 | SJ-50 | SJ-60 | SJ-80 | SJ-100 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| General | |||||||||||

| Steam Output From & at 100°C | Kg/hr | 500 | 1000 | 1500 | 2000 | 3000 | 4000 | 5000 | 6000 | 8000 | 10000 |

| Working Pressure | Kg/CM² | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 |

| Steam Temprature | °C | 183 | 183 | 183 | 183 | 183 | 183 | 183 | 183 | 184 | 185 |

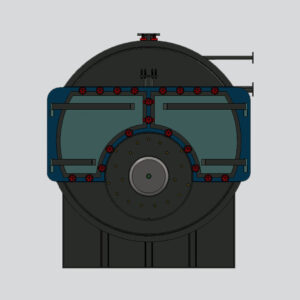

| No’s Passes | No’s | Three | Three | Three | Three | Three | Three | Three | Three | Three | Three |

| No’s of Furnace | No’s | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| Steam Outlet | MM | 40 | 50 | 80 | 80 | 100 | 100 | 125 | 150 | 150 | 200 |

| HTA | M² | 15 | 30 | 45 | 60 | 90 | 120 | 150 | 180 | 240 | 300 |

| Burner: Pressure jet Monoblock Burner | |||||||||||

| Type of Fuel: Diesel, LPG, NG, PNG, FO, LDO | |||||||||||

| Boilers Efficiency | |||||||||||

| On Gas | % | 90 +/-2 | 90 +/-2 | 90 +/-2 | 90 +/-2 | 90 +/-2 | 90 +/-2 | 90 +/-2 | 90 +/-2 | 90 +/-2 | 90 +/-2 |

| On Oil | % | 88 +/-2 | 88 +/-2 | 88 +/-2 | 88 +/-2 | 88 +/-2 | 88 +/-2 | 88 +/-2 | 88 +/-2 | 88 +/-2 | 88 +/-2 |

| Fuel Consumption | |||||||||||

| Diesel (10500) | Kg/hr | 29 | 58 | 88 | 117 | 175 | 234 | 292 | 351 | 468 | 584 |

| Furnace Oil (9600) | Kg/hr | 32 | 64 | 96 | 128 | 192 | 256 | 320 | 384 | 511 | 639 |

| LDO (10200) | Kg/hr | 30 | 60 | 90 | 120 | 180 | 241 | 301 | 361 | 481 | 602 |

| LPG (11000) | Kg/hr | 30 | 60 | 90 | 120 | 180 | 241 | 301 | 361 | 481 | 602 |

| Natural gas(8900) | M³/hr | 34 | 67 | 101 | 135 | 202 | 270 | 337 | 404 | 539 | 674 |

| Electrical Load | |||||||||||

| Feed Water Pump | H.P. | 2.00 | 2.00 | 3.00 | 3.00 | 4.00 | 4.00 | 6.00 | 7.50 | 10.00 | 15.00 |

| Burner Blower (oil) | H.P. | 0.37 | 1.10 | 3.00 | 3.00 | 5.50 | 7.50 | 7.50 | 11.00 | 18.5 | 18.5 |

| Fuel Pump | H.P. | * | * | * | * | 1.10 | 1.10 | 1.10 | 1.50 | 3.0 | 3.0 |

| Total Electric Load | H.P. | 2.37 | 3.10 | 6.00 | 6.00 | 10.60 | 12.60 | 14.60 | 20.00 | 31.50 | 36.50 |

| NOTE: In view of constant endeavors to improve our products, we reserve the right to alter or change above specifications without prior notice. | |||||||||||

Frequently Asked Questions

Can this boiler switch between PNG and LPG?

Yes. By using a Dual-Fuel or Multi-Fuel burner, the system can seamlessly switch between Piped Natural Gas and Liquid Petroleum Gas (LPG) depending on availability.

What is the thermal efficiency of this 5 TPH gas boiler?

Our gas-fired units operate at 90% to 92% efficiency, which can be boosted to 95% - 98% when integrated with a condensing economizer.

Is PNG cheaper to run than Diesel for a 5 Ton capacity?

In most industrial clusters, PNG offers a 20% to 30% saving in fuel costs compared to HSD (Diesel), while providing much cleaner combustion.

How does the boiler ensure complete combustion of gas?

We utilize high-precision Modulating Burners that automatically adjust the air-to-fuel ratio across the entire firing range for maximum efficiency.

What is the steam output of this model?

The rated capacity is 5000 Kg/hr (5.0 TPH) of high-quality dry saturated steam.

What are the standard working pressure options?

The standard design is for 10.54 Kg/cm², with high-pressure custom versions available up to 21 Kg/cm².

Is this 5 Ton boiler IBR compliant?

Yes, all 5 TPH gas boilers are fully IBR (Indian Boiler Regulations) certified, ensuring safety and legal compliance.

What is the advantage of a "3-Pass Wet Back" design for gas?

It maximizes heat transfer and eliminates the need for a rear refractory arch (which is prone to cracking), reducing long-term maintenance costs and heat loss.

What burner brands are used for the 5 TPH range?

We equip these units with premium European burners such as ELCO (Germany), Riello (Italy), or equivalent world-class brands.

What automation features are included?

The boiler features a PLC-based HMI touch panel for fully automatic operation, including auto-start, pressure modulation, and data logging.

Does the boiler have a gas leak detection system?

Yes, for safety, the gas train includes a Valve Proving System (VPS) and optional ambient gas sensors to detect and shut down the system in case of leaks.

How does the boiler handle sudden peaks in steam demand?

The large shell diameter and high water volume provide a "thermal flywheel" effect, maintaining stable pressure even when the factory suddenly opens large steam valves.

What safety interlocks are standard?

Standard interlocks include high/low gas pressure switches, air pressure switches, dual low-water cut-offs, and flame scanners.

Can I monitor this boiler via my smartphone?

Yes, we offer an optional IoT Remote Monitoring System that allows you to track fuel consumption and boiler status in real-time.

What is the electrical connected load for a 5 TPH gas boiler?

The total load, including the burner motor and feedwater pumps, is approximately 15 HP to 20 HP.

Is the 5 Ton gas boiler available as a skid-mounted unit?

Yes, we provide complete skid-mounted solutions where the boiler, gas train, and feed pumps are integrated for faster site installation.

What kind of chimney is required for a PNG boiler?

While gas is clean, a chimney is required to discharge flue gases. Typically, a 30-meter stack is standard to meet environmental norms, though the diameter is smaller than coal boilers.

How often should the gas train be inspected?

We recommend a monthly check of the gas filters and valves, with a professional burner calibration every 6 months to maintain peak efficiency.

Does Indian Boilers provide IBR renewal services in Ahmedabad?

Yes, our Ahmedabad team provides end-to-end support for annual IBR inspections, burner tuning, and genuine spare parts.

Reviews

There are no reviews yet.