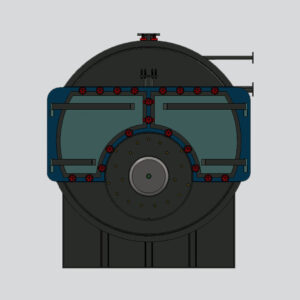

2 Ton Oil Fired Steam Boiler (2000 Kg/hr)

High-Performance Steam | German Burner Technology | Rapid Steam Generation

At IndianBoilers.com, our 2 Ton Oil Fired Steam Boilers are engineered to provide maximum thermal output within a compact industrial footprint. Designed for high-demand applications, these boilers utilize Light Diesel Oil (LDO) or High-Speed Diesel (HSD) to deliver precise temperature control and ultra-efficient combustion.

Manufactured in Ahmedabad, our 2 TPH units feature the STEAMJET series design—a 100% skid-mounted, plug-and-play system that ensures your facility is up and running with minimal installation time.

Key Features & Performance

- 95% Thermal Efficiency: Achieve an overall efficiency of up to 95% when integrated with our advanced sensible heat recovery units.

- World-Class Combustion: Equipped with mono-block, dual-block, or steam-atomized burners featuring world-renowned technology from ELCO-Germany.

- High Dryness Fraction: Specifically designed to produce steam with a high dryness fraction, which increases the usable heat available for your process.

- Plug-and-Play Setup: The 2 Ton model is 100% skid-mounted, allowing for easy transportation and immediate onsite commissioning.

- Large Water Reserve: Built with a large water holding capacity to manage sudden load surges without compromising steam pressure or quality.

- Advanced Monitoring: Features intelligent panels for comprehensive boiler monitoring and control, ensuring safe and optimized operation 24/7.

- Precision Control: Optional 3-element control systems for close monitoring of water level, steam flow, and feedwater flow.

Operating Range

Our 2 Ton Oil Fired Boiler is built for industrial endurance and high-pressure reliability.

- 1. Capacity: 2.0 TPH (2000 Kg/hr) — Available within our scaling range of 0.5 TPH to 10 TPH.

- 2. Fuel Options: Light Oils (LDO/HSD), Heavy Oils, and Gaseous fuels.

- 3. Working Pressure: Standard designs accommodate pressures from 10.54 Kg/cm2 to 21 Kg/cm2.

- 4. Design Type: 3-Pass Smoke Tube with integral furnace and spirals in the tubes for a high rate of heat transfer.

Core Industry Applications

The 2 Ton Oil Fired Boiler is the “Gold Standard” for:

- Chemical Processing: Reliable steam for reactors and jacketed vessels.

- Textiles: Consistent heat for high-volume dyeing and finishing.

- Pharmaceuticals: Precise sterilization and bulk drug manufacturing.

- Food & Dairy: Pasteurization and large-scale industrial cooking.

Advantages

By choosing IndianBoilers.com, you invest in premium quality backed by local support:

- Lower Stack Temperatures: Our design ensures low stack temperatures at the boiler outlet, meaning more heat stays in your process and less goes up the chimney.

- Easy Maintenance: Features a hinged smoke chamber, making the cleaning of tubes easy and facilitating the settling of ash.

- Local Expertise: As an Ahmedabad-based manufacturer, we provide rapid response for IBR certification, spares, and technical service.

Technical Specifications

| Specification | Unit | SJ-05 | SJ-10 | SJ-15 | SJ-20 | SJ-30 | SJ-40 | SJ-50 | SJ-60 | SJ-80 | SJ-100 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| General | |||||||||||

| Steam Output From & at 100°C | Kg/hr | 500 | 1000 | 1500 | 2000 | 3000 | 4000 | 5000 | 6000 | 8000 | 10000 |

| Working Pressure | Kg/CM² | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 |

| Steam Temprature | °C | 183 | 183 | 183 | 183 | 183 | 183 | 183 | 183 | 184 | 185 |

| No’s Passes | No’s | Three | Three | Three | Three | Three | Three | Three | Three | Three | Three |

| No’s of Furnace | No’s | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| Steam Outlet | MM | 40 | 50 | 80 | 80 | 100 | 100 | 125 | 150 | 150 | 200 |

| HTA | M² | 15 | 30 | 45 | 60 | 90 | 120 | 150 | 180 | 240 | 300 |

| Burner: Pressure jet Monoblock Burner | |||||||||||

| Type of Fuel: Diesel, LPG, NG, PNG, FO, LDO | |||||||||||

| Boilers Efficiency | |||||||||||

| On Gas | % | 90 +/-2 | 90 +/-2 | 90 +/-2 | 90 +/-2 | 90 +/-2 | 90 +/-2 | 90 +/-2 | 90 +/-2 | 90 +/-2 | 90 +/-2 |

| On Oil | % | 88 +/-2 | 88 +/-2 | 88 +/-2 | 88 +/-2 | 88 +/-2 | 88 +/-2 | 88 +/-2 | 88 +/-2 | 88 +/-2 | 88 +/-2 |

| Fuel Consumption | |||||||||||

| Diesel (10500) | Kg/hr | 29 | 58 | 88 | 117 | 175 | 234 | 292 | 351 | 468 | 584 |

| Furnace Oil (9600) | Kg/hr | 32 | 64 | 96 | 128 | 192 | 256 | 320 | 384 | 511 | 639 |

| LDO (10200) | Kg/hr | 30 | 60 | 90 | 120 | 180 | 241 | 301 | 361 | 481 | 602 |

| LPG (11000) | Kg/hr | 30 | 60 | 90 | 120 | 180 | 241 | 301 | 361 | 481 | 602 |

| Natural gas(8900) | M³/hr | 34 | 67 | 101 | 135 | 202 | 270 | 337 | 404 | 539 | 674 |

| Electrical Load | |||||||||||

| Feed Water Pump | H.P. | 2.00 | 2.00 | 3.00 | 3.00 | 4.00 | 4.00 | 6.00 | 7.50 | 10.00 | 15.00 |

| Burner Blower (oil) | H.P. | 0.37 | 1.10 | 3.00 | 3.00 | 5.50 | 7.50 | 7.50 | 11.00 | 18.5 | 18.5 |

| Fuel Pump | H.P. | * | * | * | * | 1.10 | 1.10 | 1.10 | 1.50 | 3.0 | 3.0 |

| Total Electric Load | H.P. | 2.37 | 3.10 | 6.00 | 6.00 | 10.60 | 12.60 | 14.60 | 20.00 | 31.50 | 36.50 |

| NOTE: In view of constant endeavors to improve our products, we reserve the right to alter or change above specifications without prior notice. | |||||||||||

Frequently Asked Questions

What types of oil can be used in this boiler?

This versatile unit is designed to fire HSD (Diesel), LDO (Light Diesel Oil), and Furnace Oil (FO).

What is the fuel consumption for a 2 TPH unit?

When firing Diesel (HSD), the consumption is approximately 125 to 135 Liters per hour at full load, depending on the feedwater temperature.

What is the thermal efficiency of this boiler?

The STEAMJET series achieves 88% efficiency on its own, which can be increased to 95% with the integration of our sensible heat recovery units (Economizers).

How does the boiler handle heavy fuels like Furnace Oil?

For FO firing, we provide a specialized burner and a fuel pre-heating system (outflow heaters) to ensure the oil reaches the correct viscosity for perfect atomization.

What is the standard design pressure?

The standard working pressure is 10.54 Kg/cm², but we offer custom high-pressure models up to 21 Kg/cm².

Is this 2 Ton boiler IBR compliant?

Yes, our 2 Ton oil-fired units are fully IBR (Indian Boiler Regulations) certified, manufactured with IBR-approved boiler-quality steel plates.

What burner technology is used?

We use premium ELCO-Germany or equivalent dual-block burners, which offer high-precision combustion and low noise levels.

What is a "3-Pass Wet Back" design?

This design forces flue gases to pass through the water three times for maximum heat transfer. The "Wet Back" feature means the rear reversal chamber is completely surrounded by water, eliminating the need for heavy refractory maintenance.

What are the electrical power requirements?

The system typically requires a 3-phase, 415V supply with a total connected load of approximately 7.5 HP to 10 HP for the burner blower and feed pumps.

Is the boiler operation automated?

Yes, it features a Fully Automatic Control Panel that manages the firing cycle, water level maintenance, and pressure control with zero manual intervention required.

Does it include a "Low Water Cut-Off" system?

Absolutely. The boiler is equipped with redundant safety systems that automatically shut down the burner if the water level drops below a safe threshold.

What is the "3-Element Control System" option?

For the 2 Ton model, we offer a 3-element system that monitors steam flow, water level, and feedwater flow simultaneously for ultra-precise boiler stability.

How many safety valves are provided?

As per IBR standards, we provide two independent spring-loaded safety valves to ensure the boiler never exceeds its maximum allowable pressure.

Can this boiler be monitored remotely?

Yes, we offer optional IoT integration that allows you to monitor steam pressure, fuel consumption, and stack temperature via a mobile app or desktop dashboard.

Is the 2 Ton boiler available as a skid-mounted unit?

Yes, we specialize in 100% skid-mounted, plug-and-play configurations. The boiler, pumps, and controls are integrated on a single frame to minimize on-site civil work.

How easy is it to clean the smoke tubes?

Our design features hinged front and rear doors, allowing easy access for mechanical tube cleaning without the need to dismantle the burner or piping.

How long does it take to generate steam from a cold start?

The 2 Ton oil-fired unit typically reaches its full working pressure within 30 to 45 minutes from a cold start.

What kind of water treatment is necessary?

To protect the 2 TPH unit from scale and corrosion, we recommend using a Water Softener to maintain hardness below 5 ppm.

Does Indian Boilers provide AMC services in Ahmedabad?

Yes, our Ahmedabad team provides comprehensive Annual Maintenance Contracts, including burner tuning, IBR renewal assistance, and genuine spare parts support.

Reviews

There are no reviews yet.