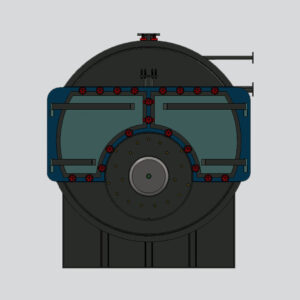

1 Ton Natural Gas Fired Steam Boiler (1000 Kg/hr)

Clean Energy | Ultra-High Efficiency | Fully Automated Steam Solutions

At IndianBoilers.com, our 1 Ton Natural Gas Fired Steam Boilers are the preferred choice for industries prioritizing environmental compliance and operational ease. Natural gas offers the cleanest combustion of all fossil fuels, eliminating the need for complex ash handling or heavy soot management.

Manufactured in our Ahmedabad facility, these boilers are engineered for precision, utilizing advanced burner technology to deliver instant, high-quality steam with a carbon footprint significantly lower than coal or oil-fired units.

Key Features & Performance

- Maximum Thermal Efficiency: Achieves an overall efficiency of up to 95% when integrated with sensible heat recovery units.

- Plug-and-Play Design: Features a 100% skid-mounted configuration for rapid installation and “Plug and Play” operation.

- High-Quality Dry Steam: Delivers steam with a high dryness fraction, which increases usable heat for your industrial processes.

- World-Class Combustion: Equipped with mono-block or dual-block burners featuring world-renowned technology from ELCO-Germany.

- Advanced Monitoring: Includes panels for advanced boiler monitoring and control, ensuring safe and optimized performance.

- Precision Water Management: Optional 3-element control systems are available for close monitoring of water level, steam flow, and feedwater flow.

- Large Water Reserve: Designed with a large water holding capacity to handle load fluctuations without dropping pressure.

Operating Range

Our 1 Ton Gas Boiler is part of the premium STEAMJET series, built for high-performance industrial environments.

- 1. Capacity: 1.0 TPH (1000 Kg/hr) — Scaling available from 0.5 TPH to 10 TPH.

- 2. Fuel Versatility: Optimized for Natural Gas (PNG), but also compatible with LPG and Light Oils.

- 3. Working Pressure: Standard designs from 10.54 Kg/cm2 to 21 Kg/cm2.

- 4. Compliance: Fully IBR (Indian Boiler Regulations) approved for legal safety and insurance compliance.

Core Industry Applications

The 1 Ton Natural Gas Boiler is ideal for:

- Food & Beverage: Clean steam for cooking, pasteurization, and CIP systems.

- Pharmaceuticals: Sterile steam for autoclaves and chemical synthesis.

- Hotels & Hospitals: Centralized laundry and ultra-quiet steam generation.

- Textiles: High-efficiency dyeing and finishing processes.

Advantages

By choosing IndianBoilers.com, you access Gujarat’s leading engineering standards:

- Low Emissions: Our gas-fired units easily meet the most stringent GPCB (Gujarat Pollution Control Board) norms.

- Compact Footprint: No fuel storage tanks or large ash pits required, saving valuable factory floor space.

- Expert Support: Our Ahmedabad-based team provides 24/7 technical support and genuine spare parts for your ELCO burner systems.

Technical Specifications

| Specification | Unit | SJ-05 | SJ-10 | SJ-15 | SJ-20 | SJ-30 | SJ-40 | SJ-50 | SJ-60 | SJ-80 | SJ-100 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| General | |||||||||||

| Steam Output From & at 100°C | Kg/hr | 500 | 1000 | 1500 | 2000 | 3000 | 4000 | 5000 | 6000 | 8000 | 10000 |

| Working Pressure | Kg/CM² | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 |

| Steam Temprature | °C | 183 | 183 | 183 | 183 | 183 | 183 | 183 | 183 | 184 | 185 |

| No’s Passes | No’s | Three | Three | Three | Three | Three | Three | Three | Three | Three | Three |

| No’s of Furnace | No’s | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| Steam Outlet | MM | 40 | 50 | 80 | 80 | 100 | 100 | 125 | 150 | 150 | 200 |

| HTA | M² | 15 | 30 | 45 | 60 | 90 | 120 | 150 | 180 | 240 | 300 |

| Burner: Pressure jet Monoblock Burner | |||||||||||

| Type of Fuel: Diesel, LPG, NG, PNG, FO, LDO | |||||||||||

| Boilers Efficiency | |||||||||||

| On Gas | % | 90 +/-2 | 90 +/-2 | 90 +/-2 | 90 +/-2 | 90 +/-2 | 90 +/-2 | 90 +/-2 | 90 +/-2 | 90 +/-2 | 90 +/-2 |

| On Oil | % | 88 +/-2 | 88 +/-2 | 88 +/-2 | 88 +/-2 | 88 +/-2 | 88 +/-2 | 88 +/-2 | 88 +/-2 | 88 +/-2 | 88 +/-2 |

| Fuel Consumption | |||||||||||

| Diesel (10500) | Kg/hr | 29 | 58 | 88 | 117 | 175 | 234 | 292 | 351 | 468 | 584 |

| Furnace Oil (9600) | Kg/hr | 32 | 64 | 96 | 128 | 192 | 256 | 320 | 384 | 511 | 639 |

| LDO (10200) | Kg/hr | 30 | 60 | 90 | 120 | 180 | 241 | 301 | 361 | 481 | 602 |

| LPG (11000) | Kg/hr | 30 | 60 | 90 | 120 | 180 | 241 | 301 | 361 | 481 | 602 |

| Natural gas(8900) | M³/hr | 34 | 67 | 101 | 135 | 202 | 270 | 337 | 404 | 539 | 674 |

| Electrical Load | |||||||||||

| Feed Water Pump | H.P. | 2.00 | 2.00 | 3.00 | 3.00 | 4.00 | 4.00 | 6.00 | 7.50 | 10.00 | 15.00 |

| Burner Blower (oil) | H.P. | 0.37 | 1.10 | 3.00 | 3.00 | 5.50 | 7.50 | 7.50 | 11.00 | 18.5 | 18.5 |

| Fuel Pump | H.P. | * | * | * | * | 1.10 | 1.10 | 1.10 | 1.50 | 3.0 | 3.0 |

| Total Electric Load | H.P. | 2.37 | 3.10 | 6.00 | 6.00 | 10.60 | 12.60 | 14.60 | 20.00 | 31.50 | 36.50 |

| NOTE: In view of constant endeavors to improve our products, we reserve the right to alter or change above specifications without prior notice. | |||||||||||

Frequently Asked Questions

What is the thermal efficiency of this model?

Our 1 Ton Natural Gas boiler achieves a thermal efficiency of up to 95% when integrated with our advanced heat recovery units (Economizers).

How much Natural Gas (PNG) does the boiler consume per hour?

At full load, the consumption is approximately 67 NM³/hr, based on a standard calorific value of 8500 Kcal/NM³.

How long does it take to reach full operating pressure from a cold start?

Depending on the design (Coil vs. Shell type), our gas-fired units can generate usable steam in as little as 10–15 minutes for coil types and slightly longer for high-reserve shell types.

Can this boiler handle fluctuating steam loads?

Yes, the STEAMJET SJ-10 series is designed with a large water reserve to act as a thermal buffer, ensuring stable pressure even during sudden peaks in demand.

What is the standard working pressure for this 1 Ton unit?

The standard design pressure is 10.54 Kg/cm², but we offer high-pressure variants up to 21 Kg/cm².

Is this boiler IBR (Indian Boiler Regulations) approved?

Yes, our 1 Ton gas boilers are fully IBR certified, ensuring compliance with all national safety laws and easier insurance processing.

What burner technology do you use?

We use world-class ELCO-Germany or Riello burners, featuring high-precision air-to-fuel ratio control for maximum savings.

What are the electrical requirements for this boiler?

The system typically requires a 3-phase, 415V supply. The total electrical load (including the feed pump and burner blower) is approximately 3.10 HP.

Does it come with an automated control panel?

Yes, it features a fully automated PLC-based control panel with safety interlocks for flame failure, low water level, and over-pressure.

Is the boiler delivered as a "Plug-and-Play" unit?

Yes, our 1 Ton gas boiler is 100% skid-mounted. The boiler, feed pumps, and control panel are pre-wired and pre-piped on a single frame for rapid installation.

Does it require a large chimney (flue)?

Natural gas is a clean fuel, but a chimney is still required for safe exhaust. However, the stack height is usually lower than that required for coal or wood-fired boilers.

What kind of water treatment is required?

To prevent scale formation and tube failure, we recommend using softened water with a hardness of less than 5 ppm. We can provide a matching Water Softener plant as an add-on.

How often should the burner be serviced?

We recommend a professional burner calibration every 6 months to ensure the combustion stays at peak efficiency and emissions remain within GPCB norms.

Are spare parts for the gas burner easily available in India?

As we use standard European burners (ELCO), genuine spare parts are always in stock at our Ahmedabad facility for immediate dispatch.

Can this boiler run on LPG if PNG is unavailable?

Yes, the burner can be configured for Multi-Fuel versatility, allowing it to run on Natural Gas (PNG/CNG) or LPG with minimal adjustments.

How does this boiler help with pollution control?

Natural gas offers the cleanest combustion. Our units easily meet the GPCB (Gujarat Pollution Control Board) norms for NOx and SOx emissions.

Is a fuel storage tank required?

If you are using Piped Natural Gas (PNG), no storage is required. For LPG, a manifold or specialized tank would be necessary.

What is the advantage of a 3-pass wet back design?

The 3-pass design maximizes heat extraction from the gases, while the "wet back" design eliminates fragile rear refractories, reducing maintenance costs.

Can I monitor the boiler efficiency remotely?

Yes, we offer optional IoT-enabled monitoring systems that allow you to track fuel consumption and steam output on your smartphone or computer.

Reviews

There are no reviews yet.