-

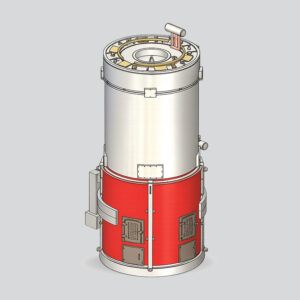

Industrial Boiler

Gas-Fired Industrial Steam Boiler 200 Kg/hr – Natural Gas/LPG

₹490,000.00 Add to cart

High-Capacity Horizontal Steam Boilers: Robust Thermal Solutions

At IndianBoilers.com, our Horizontal Steam Boilers are engineered for industries that demand high-volume steam and uncompromising reliability. Designed with a traditional horizontal shell-and-tube architecture, these boilers provide a larger steam space and a longer flue gas path, ensuring superior heat transfer and the ability to handle fluctuating steam loads with ease.

Key Features & Performance

- 3-Pass Fully Wet Back Design: Maximizes heat absorption and eliminates the need for rear-end refractory, significantly reducing maintenance and preventing tube-sheet cooling issues.

- Multi-Fuel Versatility: Our horizontal units are optimized for a wide range of fuels, including Furnace Oil, LDO, Natural Gas, Coal, and Agro-waste, offering you the flexibility to choose the most cost-effective energy source.

- Superior Steam Quality: Large water-holding capacity and significant steam disengaging area ensure the production of high-dryness saturated steam even during peak demand.

- High Thermal Efficiency: Achieves 82% to 88% efficiency with integrated heat recovery units like Economizers and Air Pre-Heaters (APH).

- IBR Certified Safety: Manufactured strictly under Indian Boiler Regulations (IBR) using premium boiler-quality steel plates (SA 515/516 Gr. 70) for maximum safety and longevity.

Technical Specifications

| Specification | Details |

| Capacity Range | 1.0 TPH to 25.0 TPH |

| Working Pressure | 10.54 kg/cm² to 32 kg/cm² (Customizable) |

| Fuel Options | Oil (HSD/LDO/FO), Gas (PNG/LPG), Coal, Wood, Briquettes |

| Design Type | Horizontal, 3-Pass, Internal/External Furnace |

| Automation Grade | Fully Automatic / Semi-Automatic |

| Heat Recovery | Optional Economizer, APH, or Water Pre-Heaters |

Why Choose Our Horizontal Boilers?

- Scalability: Perfect for medium to large-scale industrial operations where steam demand is high and consistent.

- Ease of Maintenance: The horizontal layout allows for easy access to smoke tubes and the furnace for routine cleaning and inspection, ensuring minimal downtime.

- Durability: Rugged construction designed for 24/7 heavy-duty industrial operation with a lifespan exceeding 20+ years.

- Low Power Consumption: Optimized draught systems (ID/FD fans) ensure efficient combustion with minimum electrical energy usage.

Core Industry Applications

Our horizontal steam systems are the backbone of various high-demand sectors across India:

- Textile & Dyeing: For continuous high-pressure steam required in processing and finishing.

- Chemical & Pharma: Precise temperature control for reactors and distillation units.

- Food & Beverage: Large-scale sterilization, pasteurization, and cooking processes.

- Paper & Packaging: Reliable thermal energy for drying and pulp processing.